High-temperature-resistant photocuring 3D printing resin material, preparation method, printing method and application

A 3D printing and resin material technology, applied in the direction of additive processing, etc., can solve the problems such as temperature resistance, mechanical strength and flexibility that cannot be comprehensively considered, affect the accuracy and surface state of printed parts, and cannot be applied in the medical field on a large scale. , to achieve the effect of being conducive to industrial production and manufacturing, fast curing speed and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

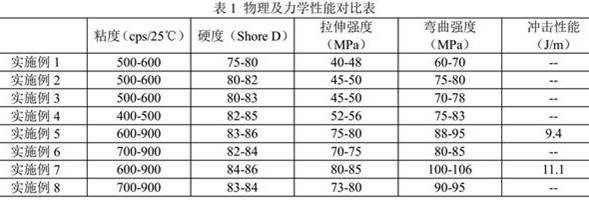

Examples

preparation example Construction

[0032] The present invention provides a method for preparing the above-mentioned high temperature resistant photocurable 3D printing resin material, comprising the following steps:

[0033] (1) Stir and mix the reactive diluent monomer and photoinitiator under light-shielding conditions until completely transparent;

[0034] (2) After the material system in step (1) is transparent, under heating conditions, add high-temperature-resistant monomers and polyurethane acrylate oligomers in turn and stir until the system is completely transparent;

[0035] (3) Under the same heating conditions, mechanically stir for 60-90min, control the speed of 500-1000rpm, disperse evenly, and perform vacuum defoaming to obtain a high-temperature resistant light-curable 3D printing resin material.

[0036] The heating conditions in steps (2)-(3) refer to heating to 40-60°C.

[0037] The present invention also provides a 3D printing method for the above-mentioned high-temperature-resistant light-...

Embodiment 1

[0039] A high temperature resistant photocurable 3D printing resin material is prepared by the following steps:

[0040] (1) Weigh 50g of N-acryloylmorpholine (reactive diluent monomer) and 5g of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide (photoinitiator) under light-shading conditions Stir to mix until completely transparent;

[0041] (2) After the material system in step (1) is transparent, add 60g of tris(2-hydroxyethyl)isocyanurate triacrylate (high temperature resistant monomer) and 90g of trifunctional phenolic aldehyde under heating conditions Epoxy resin (oligomer, viscosity 20000-30000cps / 25°C), stirred until the system is completely transparent, vacuum defoaming after mechanical stirring is completely uniform, and high temperature resistant photocurable 3D printing resin material is obtained.

[0042] Put the obtained 3D printing resin material into the resin tank of the DLP type 3D printer, set the printing model and parameters, the printing model is a mechani...

Embodiment 2

[0044] A high temperature resistant photocurable 3D printing resin material is prepared by the following steps:

[0045] (1) Weigh 50g of N-acryloylmorpholine (reactive diluent monomer) and 5g of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide (photoinitiator) under light-shading conditions Stir to mix until completely transparent;

[0046] (2) After the material system in step (1) is transparent, add 60g of tris(2-hydroxyethyl)isocyanurate triacrylate (high temperature resistant monomer) and 90g of hexafunctional polyurethane in turn under heating conditions Acrylate (oligomer, viscosity 20,000-40,000cps / 25°C) is stirred until the system is completely transparent. After the mechanical stirring is completely uniform, vacuum defoaming is obtained, and a high temperature resistant light-curable 3D printing resin material is obtained.

[0047] Put the obtained 3D printing resin material into the resin tank of the DLP type 3D printer, set the printing model and parameters, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com