Continuous preparation device and method of trifluoroacetyl chloride

A technology of trifluoroacetyl chloride and preparation device, which is applied in the preparation of acid halide, preparation of acid halide, preparation of organic compounds, etc., can solve the problems of fluoride ion corrosion equipment, glass optical trap corrosion, etc., which are difficult to solve, and achieve suppressed fracture. , The effect of inhibiting corrosion and accelerating the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

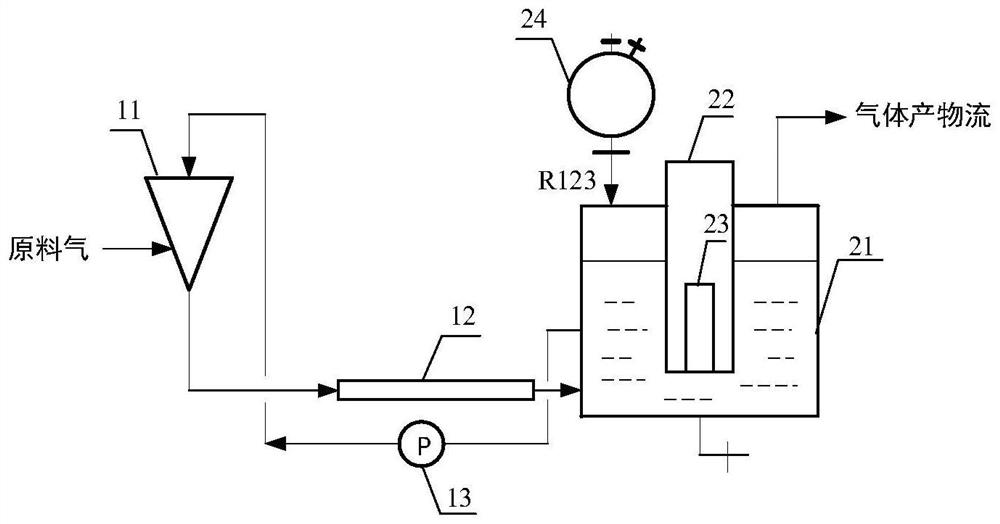

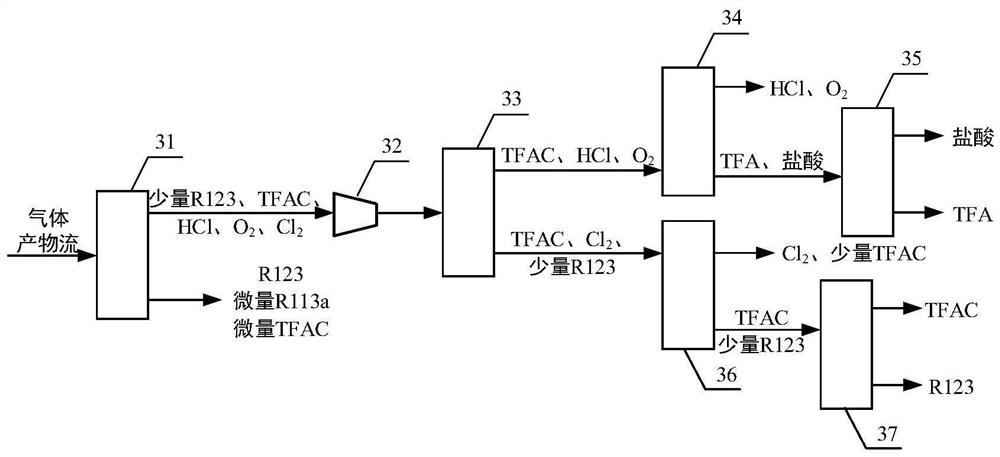

[0075] This embodiment provides a continuous preparation device for trifluoroacetyl chloride, figure 1 , figure 2 Schematically gives the structure diagram of the continuous preparation device of trifluoroacetyl chloride, as figure 1 , figure 2 Shown, described continuous preparation device comprises:

[0076] Side circulation unit, described side circulation unit comprises circulation pump 13, gas injector 11 and static mixer 12 connected in sequence, the material of reaction unit enters gas injector through circulation pump, and feed gas (oxygen and chlorine) in gas injection Mix in the container, and then return to the reaction unit to carry out the photooxidation reaction after being further mixed evenly by the static mixer;

[0077] A reaction unit, the reaction unit includes a reactor 21, a cold trap 22 placed in the reactor, a mercury lamp 23 placed in the cold trap, and a raw material storage container 24 for adding raw material R123 to the reactor, the cold The ...

Embodiment 2

[0083] This embodiment provides a continuous production method of trifluoroacetyl chloride, the continuous production method adopts the continuous production device described in Example 1, specifically: a 100L reactor is used, the mercury lamp is a 2000w high-pressure mercury lamp, and the ETFE The coating thickness of the film is 50 μm, and the rotation speed of the circulation pump is 1500 r / min.

[0084] The reaction process is as follows:

[0085] Add 80L of liquid raw material R123 into the reactor, continuously feed oxygen and chlorine under stirring, the oxygen flow rate is 1000ml / min, the chlorine flow rate is 100ml / min, and the liquid level in the reactor is kept stable by continuously adding R123. The reaction pressure was controlled at 0.1MPa, the reaction temperature was controlled at 48°C through the reactor jacket, and the reactants were continuously discharged from the gas phase outlet of the reactor in the form of gas phase.

[0086] After reacting for 24 hour...

Embodiment 3

[0090] The operation of this embodiment is the same as that of Embodiment 2, the only difference being: the Teflon AF film sprayed on the outer surface of the cold trap.

[0091] After reacting for 100 hours, the calculated TFAC content was 66.4%, the R123 content was 32.8%, the R113a content was 0.8%, and the fluoride ion content was detected to be 7ppm.

[0092] After the reaction was stopped and the cold trap was removed, it was found that there was no corrosion phenomenon on the surface of the cold trap, and no white powdery film was attached, and the light transmittance was 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com