Modified inorganic particle, preparation method thereof and application of modified inorganic particle in super-hydrophobic material

An inorganic particle and modification technology, applied in the field of coatings, can solve the problems of many preparation steps, unfriendly environment, cumbersome process, etc., and achieve the effect of good biocompatibility and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

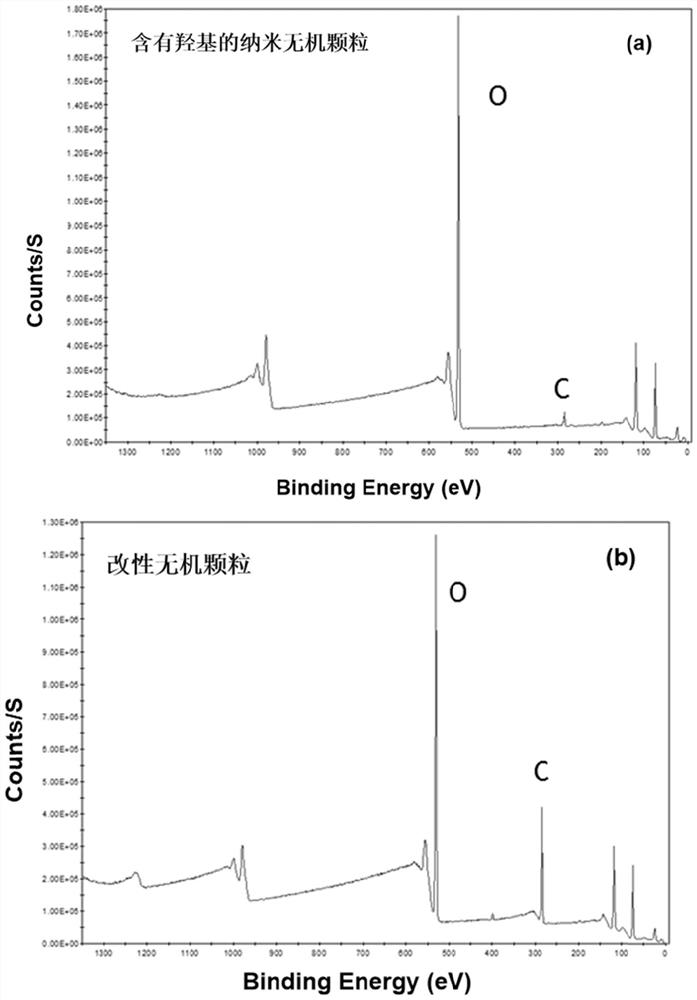

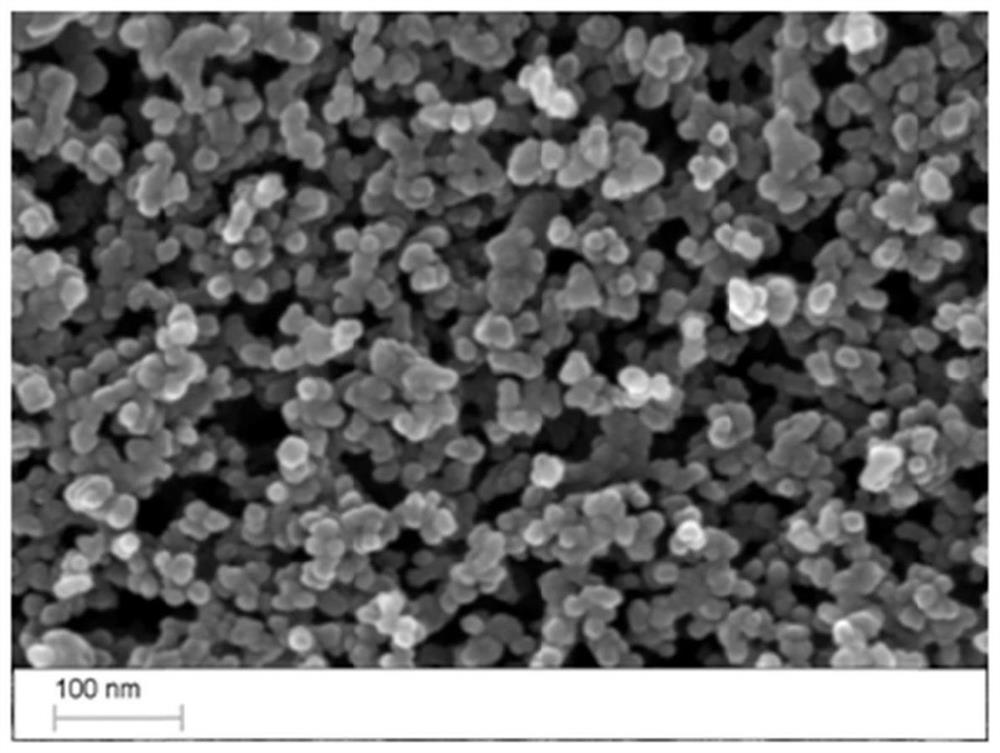

[0057] A modified Al 2 o 3 Particles, rosin modified nano-Al 2 o 3 .

[0058] The above modified Al 2 o 3 The preparation method of particle, comprises the steps:

[0059] Adopt toluene as organic solvent, configuration mass fraction is 3% rosin solution, then get 0.5 part of rosin solution and add 0.5 part of nanometer Al 2 o 3 (average particle size 13nm) and 0.02 parts of DCC and 0.02 parts of DMAP were esterified at 100°C for 12 hours, filtered and washed several times with ethanol, and dried to constant weight.

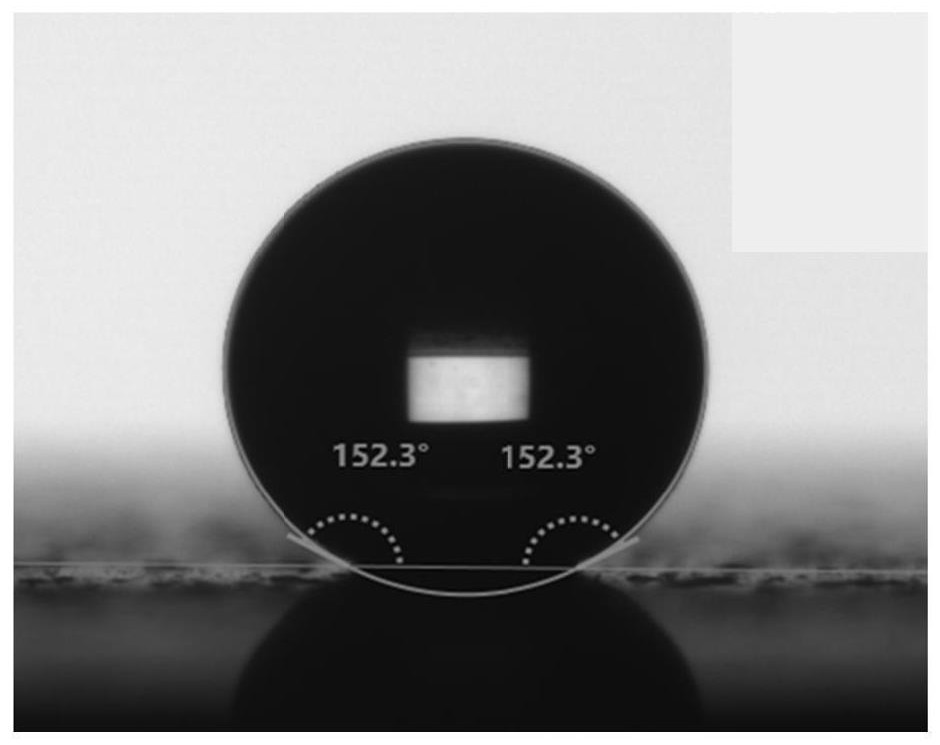

[0060] A preparation method of a bio-based antibacterial superhydrophobic coating, comprising the steps of:

[0061] Using butyl acetate as a solvent, configure a mass fraction of 5% organosilicon-modified acrylate resin solution, then get 5 parts of organosilicon-modified acrylate resin solution and add the above-mentioned 0.8 part of dried modified Al 2 o 3 The particles were uniformly dispersed to prepare a coating; the above coating was sprayed on t...

Embodiment 2

[0063] A modified SiO 2 Particles, nano-SiO modified by dehydroabietic 2 .

[0064] The above modified SiO 2 The preparation method of particle, comprises the steps:

[0065] Adopt ethanol as organic solvent, configuration mass fraction is the dehydroabietic solution of 2%, then take 2 parts of dehydroabietic solutions, add the nanometer SiO of 1 part 2 (average particle size 45nm) and 1 part of dilute sulfuric acid with a mass fraction of 1%, undergo esterification reaction at a certain temperature of 70° C. for 8 hours, filter and wash with ethanol several times and dry to constant weight.

[0066] A preparation method of a bio-based antibacterial superhydrophobic coating, comprising the steps of:

[0067] Adopt methyl ethyl ketone as solvent, configure the organosilicon-modified acrylic acid-polyurethane resin solution with a mass fraction of 3%, get 3 parts of organosilicon-modified acrylic-polyurethane resin solutions and add 2 parts of dried modified SiO 2 The parti...

Embodiment 3

[0069] A modified sepiolite particle is nano sepiolite modified by maleic acid rosin.

[0070] A preparation method of modified sepiolite particles, comprising the steps of:

[0071] Adopt ethanol as solvent, configuration mass fraction is the maleic acid rosin solution of 0.5%, then get 0.5 part of maleic acid rosin solution and add 0.8 part of nanometer sepiolite (average particle diameter 500nm) and 2 parts of mass fraction be 2% Dilute hydrochloric acid, esterify at a certain temperature of 70°C for 24 hours, filter and wash with ethanol several times and dry to constant weight.

[0072] A preparation method of a bio-based antibacterial superhydrophobic coating, comprising the steps of:

[0073] Using isobutyl ketone as the organic solvent, configure a silicone-modified epoxy resin solution with a mass fraction of 10%, take 10 parts of the silicone-modified epoxy resin solution, add 7 parts of dried modified sepiolite particles, and Disperse to prepare a coating; use a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com