Porphyrin-based conjugated microporous polymer photothermal conversion sponge as well as preparation and application thereof

A conjugated microporous, photothermal conversion technology, applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc. The effect of easy availability of materials and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

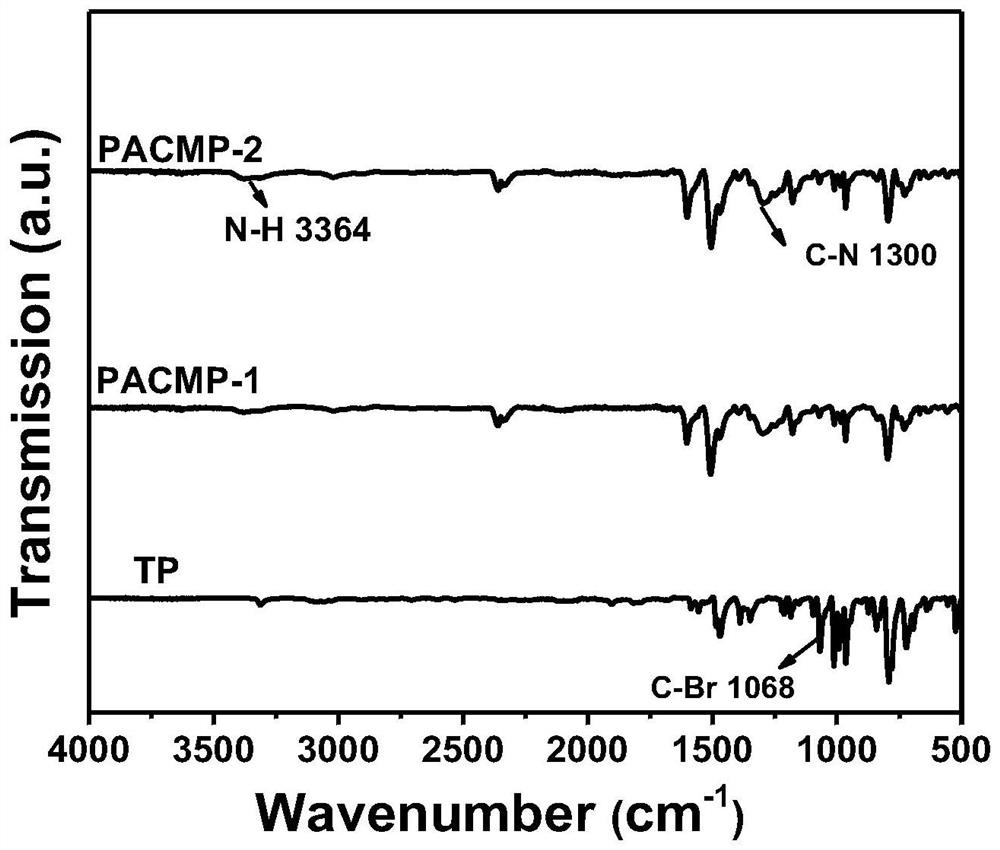

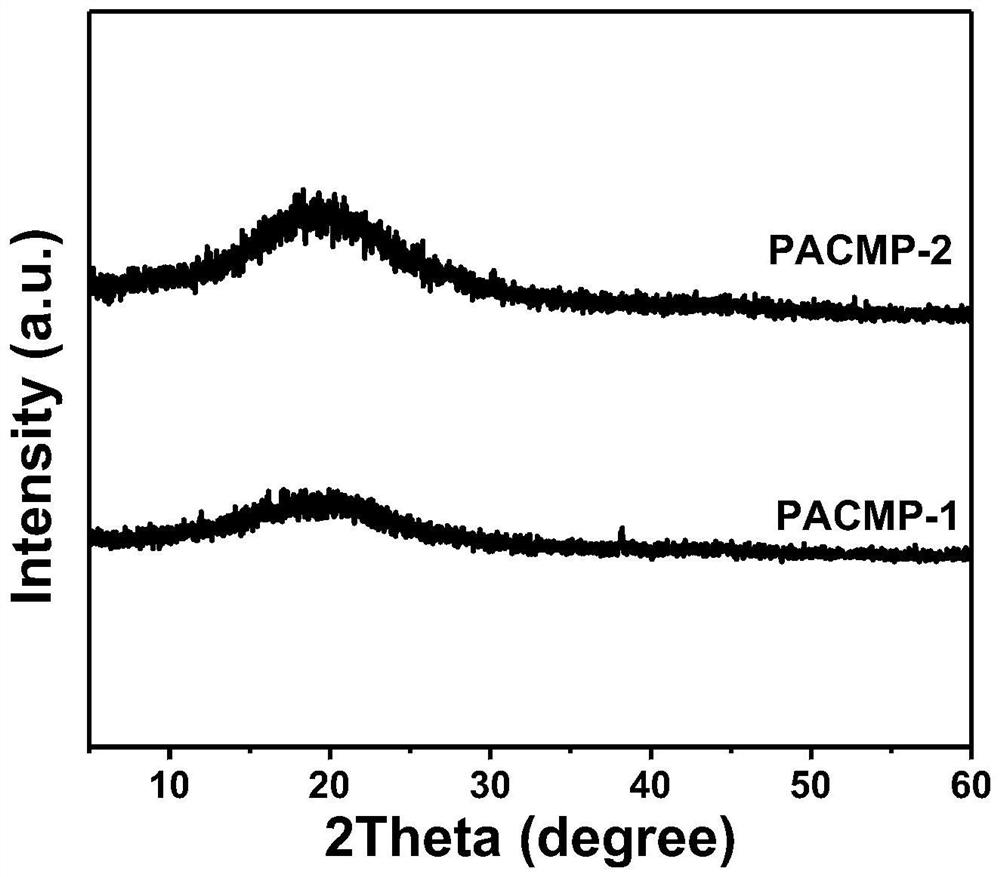

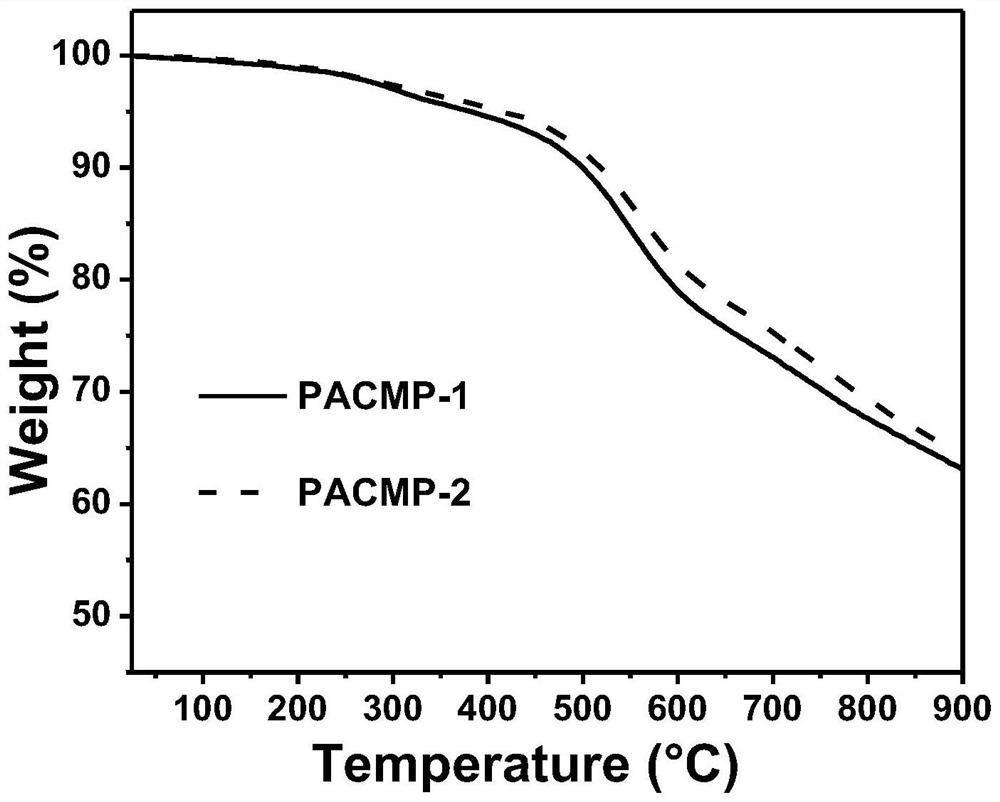

[0047] Preparation of porphyrin-based conjugated microporous polymers as light-to-heat conversion materials.

[0048] Its preparation method is: under normal temperature and pressure, put tetrabromophenylporphyrin (186mg, 0.2mmol) and p-phenylenediamine (64.8mg, 0.6mmol) into a 50mL reaction tube, add tert-butyl Sodium alkoxide (100mg, 1.04mmol), 2-dicyclohexylphosphonium-2,4,6-triisopropylbiphenyl (11.44mg, 0.024mmol), bis(dibenzylideneacetone) palladium (9.2mg, 0.016 mmol), then add 20mL anhydrous toluene under nitrogen atmosphere, react at 110°C for 48h, wash and suction filter the prepared polymer with chloroform, methanol and water, put into 100°C vacuum oven and dry for 48h to obtain porphyrin Phenyl-conjugated microporous polymer, denoted as PACMP-2.

[0049] The dosage of p-phenylenediamine in the above preparation method was modified to 21.6 mg (0.2 mmol), and the rest were the same as the above method to obtain a porphyrin-based conjugated microporous polymer, which...

Embodiment 2

[0055] Preparation of Porphyrin-Based Conjugated Microporous Polymer Modified Sponge for Seawater Desalination and Dye Wastewater Purification, Including Glucose-Chitosan Solution (Preparation Method References: Vogt, B.D.; Cavicchi, K.A.; Ye, C.; Seo, J., SOLIDSTATE CONVERSION OF BIO-BASED ORGANIC SALTS TO GENERATE POLYMER COATINGS.) and preparation of polymer modified sponges.

[0056] The preparation method is as follows: fully dissolve 7 g of D-glucose potassium salt in 100 mL of deionized water, add 30 mL of cation exchange resin, stir for 15 minutes until no particles, and obtain a mixed filtrate of glucose potassium salt and ion exchange resin. Mix the mixed filtrate with 9.1g chitosan, add deionized water and stir for 24h to form a uniform glucose-chitosan organic salt solution. The solution was purified by filtration, and the collected filtrate was rotary evaporated at a temperature of 40 °C to obtain a glucose-chitosan adhesive. Before use, 300 mL of methanol was ad...

Embodiment 3

[0060] The application of porphyrin-based conjugated microporous polymer modified sponge in seawater desalination, the specific method is:

[0061] Add 100mL of Yellow Sea seawater to a small beaker with a diameter of 4.5cm, place the polymer sponge in Example 2 on the surface of the seawater, weigh and record the total mass of the beaker, seawater and sponge; The thermal imager records real-time temperature and infrared images. After weighing the total mass of the beaker, seawater and sponge, the results are as follows: Figure 7 and Figure 8 as shown, Figure 7 It shows that the polymer-loaded sponge heats up significantly under light, and the surface temperature of the polymer sponge is significantly higher than that of the pure polyurethane sponge under the same conditions; Figure 8 The evaporation rate and light-to-heat conversion efficiency of polymer sponge and pure polyurethane sponge to seawater under light are shown, indicating that by loading a reasonable mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com