Graphene oxide coated ceramic particle corrosion-resistant gradient coating and preparation method thereof

A graphene-coated, ceramic particle technology, applied in coating, metal material coating process, heating inorganic powder coating and other directions, can solve the problem of reducing the corrosion resistance of the coating, increasing the porosity of the coating instead of decreasing, oxidation Problems such as low graphene dispersibility, to achieve the effect of improving bonding strength, avoiding decomposition, and improving antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

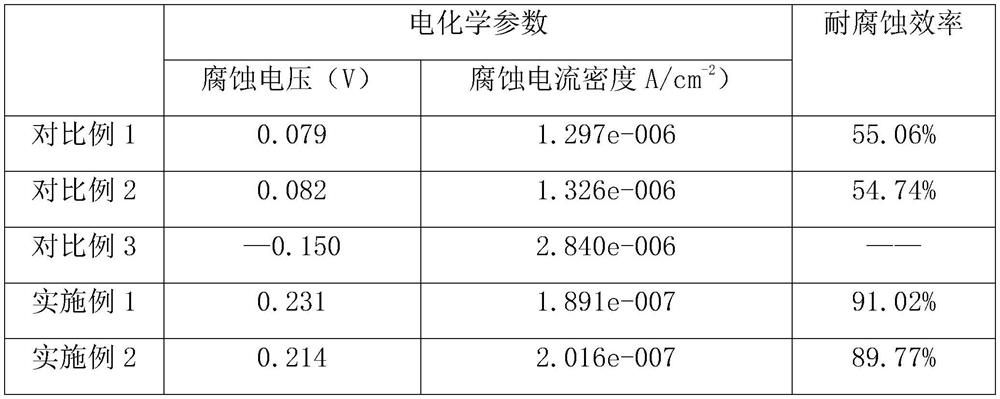

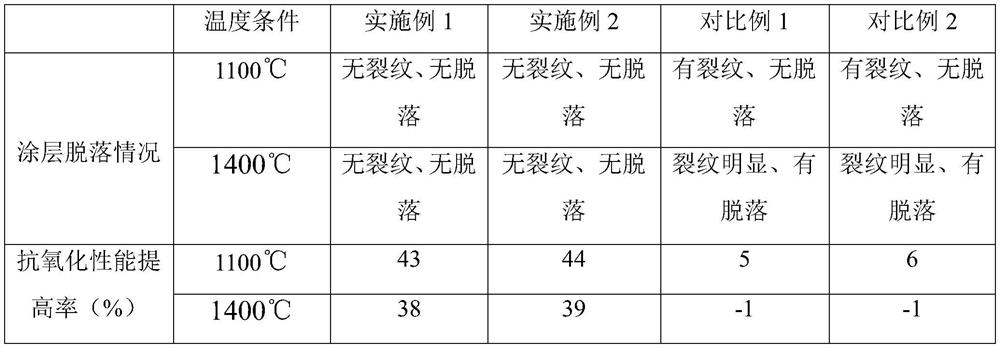

Examples

preparation example Construction

[0028] The invention provides a method for preparing a graphene oxide-coated ceramic particle corrosion-resistant gradient coating, the steps of which are as follows:

[0029] (1) Preparation of graphene oxide-coated ceramic particles

[0030] S1. Take 10wt% ethanol solution, add a small amount of dispersant, stir evenly, add nano-graphene oxide powder, gradually heat up to 50°C-90°C under stirring condition, and add dispersant dropwise under stirring, and stir to react After 1h-2h, obtain the dispersion slurry of graphene oxide;

[0031] S2, according to Cr3C2 ceramic powder and graphene oxide powder mass ratio is (1~4): 1 ratio, in above-mentioned dispersion slurry of graphene oxide, add Cr3C2 ceramic powder and grinding ball, and join in the ball mill, at 70- Grinding for 6-18 hours at a ball milling speed of 160 rpm, then taking out and separating the slurry obtained by grinding, drying and classifying to obtain graphene oxide-coated ceramic particles;

[0032] (2) Prepa...

Embodiment 1

[0043] (1) Preparation of graphene oxide-coated ceramic particles

[0044]S1. Take 100mL of 10wt% ethanol solution, add 0.4g dispersant 3-aminopropyltriethoxysilane, stir evenly, add 8g nano-graphene oxide powder, and gradually heat up to 85°C under stirring conditions, And continue to drop 0.6g dispersant under stirring, after stirring and reacting for 2h, the dispersion slurry of graphene oxide is obtained;

[0045] S2. Add 16g of Cr3C2 ceramic powder and grinding balls to the above-mentioned graphene oxide dispersion slurry, and add them to the ball mill, and grind for 12 hours at 100 rpm ball milling speed, then take out the slurry obtained by grinding and separate, after drying Drying and grading treatment to obtain graphene oxide-coated ceramic particles;

[0046] The particle size of the Cr3C2 ceramic powder is 4-10 μm, and the particle size of the graphene oxide is 0.5-3 μm;

[0047] (2) Preparation of graphene oxide-coated ceramic particles

[0048] S1. Add 0.5g of...

Embodiment 2

[0054] (1) Preparation of graphene oxide-coated ceramic particles

[0055] S1. Take 100mL of 10wt% ethanol solution, add 0.3g dispersant tetraethyl orthosilicate, stir evenly, add 5g nano-graphene oxide powder, gradually heat up to 85°C under stirring condition, and continue stirring 0.4g dispersant was added dropwise, and after stirring and reacting for 2h, a dispersion slurry of graphene oxide was obtained;

[0056] S2. Add 15g of Cr3C2 ceramic powder and grinding balls to the above-mentioned graphene oxide dispersion slurry, and add them to a ball mill, grind for 12 hours at a ball mill speed of 100 rpm, then take out and separate the slurry obtained by grinding, and bake Drying and grading treatment to obtain graphene oxide-coated ceramic particles;

[0057] The particle size of the Cr3C2 ceramic powder is 4-10 μm, and the particle size of the graphene oxide is 0.5-3 μm;

[0058] (2) Preparation of graphene oxide-coated ceramic particles

[0059] S1. Add 0.5g of 3-amino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com