A method of coating nano-starch microspheres by atomic layer deposition

An atomic layer deposition and nanostarch technology, which is applied in the fields of nanotechnology, nanomagnetism, and nanotechnology for materials and surface science. problem, to achieve the effect of favoring stability, increasing magnetic content, and narrowing particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

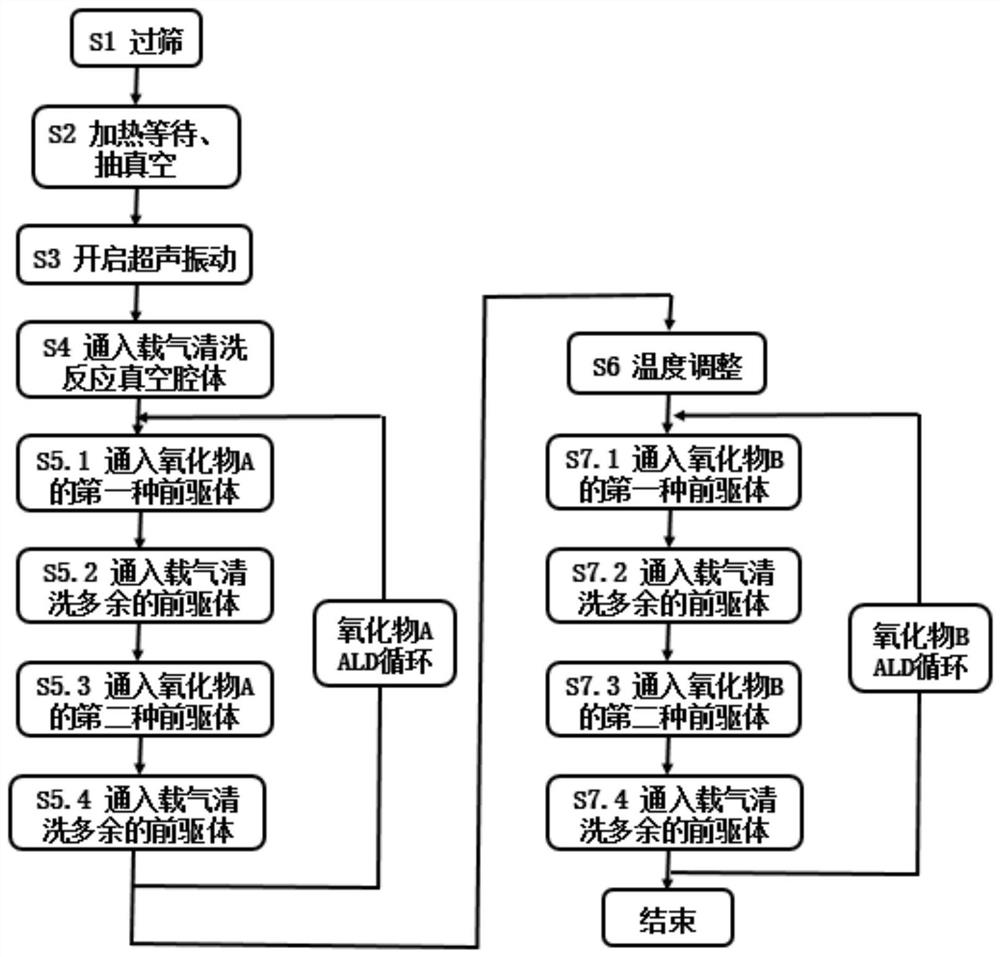

Method used

Image

Examples

Embodiment 1

[0034] A method of coating nano-starch microspheres by atomic layer deposition, surface modification of nano-starch microspheres with a particle size of 20nm, coating 5nm Fe 2 o 3 Thin films and 1nm Al 2 o 3 Thin film, where C is selected 10 h 10 Fe / O 3 , Al(CH 3 ) 3 / H 2 O is a precursor, which specifically includes the following steps:

[0035] (1) Iron oxide coating:

[0036] 1.1 After passing the nano-starch microspheres through the 800-mesh screen, weigh 5 mg and place it in the powder container of the atomic layer deposition equipment, put the powder container into the cavity, and evacuate to 10Pa;

[0037]1.2 Turn on the ultrasonic vibration, set the ultrasonic frequency to 20KHz, the working time of the ultrasonic vibration is 60s, and the intermittent time is 5s;

[0038] 1.3 Heat the cavity, and at the same time, feed the carrier gas to clean the surface of the nano-starch microspheres for 30 minutes and disperse them. The flow rate of the carrier gas is se...

Embodiment 2

[0053] A method of coating nano-starch microspheres by atomic layer deposition, surface modification of nano-starch microspheres with a particle size of 20nm, coating 5nm Fe 2 o 3 Thin films and 1nm Al 2 o 3 Thin film, where C is selected 10 h 10 Fe / O 3 , Al(CH 3 ) 3 / H 2 O is a precursor, which specifically includes the following steps:

[0054] (1) Iron oxide coating:

[0055] 1.1 After passing the nano starch microspheres through the 800 mesh screen, weigh 100g and place it in the powder container of the atomic layer deposition equipment, put the powder container into the cavity, and evacuate to 10Pa;

[0056] 1.2 Turn on the ultrasonic vibration, set the ultrasonic frequency to 40KHz, the working time of the ultrasonic vibration is 5min, and the intermittent time is 5s;

[0057] 1.3 Heat the cavity, and at the same time, pass the carrier gas to clean the surface of the nano-starch microspheres for 50 minutes and disperse them, and select the flow rate of the carr...

Embodiment 3

[0072] A method of coating nano-starch microspheres by atomic layer deposition, surface modification of nano-starch microspheres with a particle size of 10 μm, and coating with 5nm Fe 2 o 3 Thin films and 1nm SiO 2 Thin film, where C is selected 10 h 10 Fe / O 3 、SiCl 4 / H 2 O is a precursor, which specifically includes the following steps:

[0073] (1) Iron oxide coating:

[0074] 1.1 After passing the nano starch microspheres through the 800 mesh screen, weigh 200g and place it in the powder container of the atomic layer deposition equipment, put the powder container into the cavity, and evacuate to 10Pa;

[0075] 1.2 Turn on the ultrasonic vibration, set the ultrasonic frequency to 40KHz, the working time of the ultrasonic vibration is 10min, and the intermittent time is 5s;

[0076] 1.3 Heat the cavity, and at the same time pass the carrier gas to clean the surface of the nano-starch microspheres for 50 minutes and disperse them. The flow rate of the carrier gas is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com