Super-crosslinked porous polymer material capable of being dissolved and processed and preparation method of super-crosslinked porous polymer material

A technology of porous polymers and microporous polymers, applied in the direction of separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems that the surface cannot be further modified, unfavorable applications, limited application fields, etc., to achieve enhanced dispersion and Two-phase interface compatibility, good application and development prospects, simple synthesis and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a novel porous hypercrosslinked polymer PP@TB, comprising the following steps:

[0042] (1) Preparation of raw material mixture: under protective gas atmosphere, with 1.129g (6.45mmol) 1,4-p-dichlorobenzyl as monomer, 44mL 1,2-dichloroethane as solvent, reflux condensation Add the above raw materials into the three-necked flask of the tube, and use magnetic stirring for 0.5h to obtain the raw material mixture;

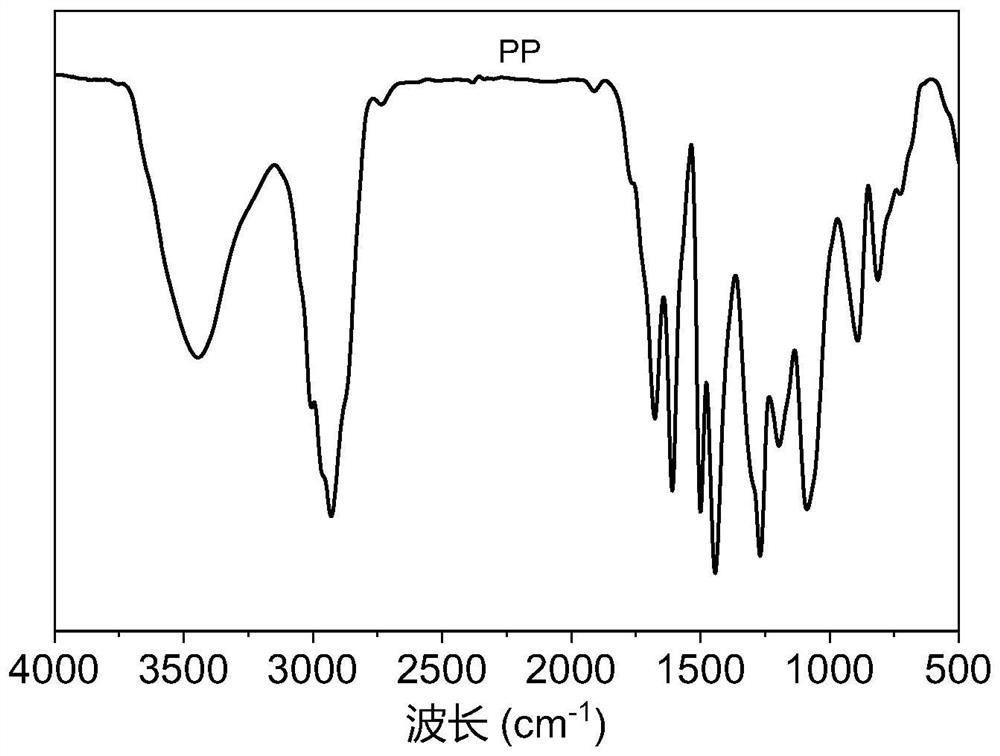

[0043] (2) Preparation of porous hypercrosslinked polymer: take anhydrous ferric chloride as catalyzer, add 1.046g (6.45mmol) catalyzer in the raw material mixed solution that obtains in step (1), Friedel-Crafts alkylation takes place Reaction, further hypercrosslinking to obtain the product PP; FT-IR such as figure 1 As shown, the successful synthesis of the PP material was verified by infrared spectroscopy.

[0044] Keep stirring continuously during the Friedel-Crafts alkylation reaction, and the specific process of temperature contr...

Embodiment 2

[0053] A preparation method of a novel porous hypercrosslinked polymer PP@PIM-1, comprising the following steps:

[0054] (1) Preparation of raw material mixture: under protective gas atmosphere, with 1.129g (6.45mmol) 1,4-p-dichlorobenzyl as monomer, 44mL 1,2-dichloroethane as solvent, reflux condensation Add the above raw materials into the three-necked flask of the tube, and use magnetic stirring for 0.5h to obtain the raw material mixture;

[0055] (2) Preparation of porous hypercrosslinked polymer: take anhydrous ferric chloride as catalyzer, add 1.046g (6.45mmol) catalyzer in the raw material mixed solution that obtains in step (1), Friedel-Crafts alkylation takes place reaction, further hypercrosslinking to obtain the product PP; FT-IR as attached figure 1 As shown, the PP material was successfully synthesized through the infrared spectrum.

[0056] Keep stirring continuously during the Friedel-Crafts alkylation reaction, and the specific process of temperature contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com