Sulfur-nitrogen doped carbon material and preparation method and application thereof

A carbon material and sulfur-nitrogen technology, which is applied in the fields of sulfur-nitrogen doped carbon material and its preparation and application, can solve the problems of scarcity of resources and high price of platinum, and achieve the effect of improving catalytic performance and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] According to the method for preparing sulfur-nitrogen-doped carbon material of the present invention, in the operation of doping sulfur, if the temperature needs to be raised, the heating rate is not lower than 8°C / min, which can be 8°C / min-15°C / min.

[0100] According to the preparation method of the sulfur-nitrogen doped carbon material of the present invention, any existing known nitrogen doping method can be used. According to the preparation method of the present invention, the operation of doping nitrogen is performed before or after the operation of doping sulfur. That is, the operation of doping nitrogen is carried out first to obtain a carbon material doped with nitrogen, and then the operation of doping sulfur with the carbon material already doped with nitrogen is carried out by the aforementioned method; or, the operation of doping sulfur is first carried out by the aforementioned method , to prepare a sulfur-doped carbon material, and then perform a nitroge...

Embodiment approach

[0112] The present invention provides a preferred embodiment, including:

[0113] (1) The step of impregnating the nitrogen source: mixing the carbon material with the nitrogen source aqueous solution and impregnating to obtain the carbon material impregnated with the nitrogen source;

[0114] (2) The step of manufacturing sulfur and nitrogen doped carbon material: place the carbon material impregnated with nitrogen source obtained in (1) in an inert gas containing thiophene, and treat it at 1000°C to 1500°C (preferably constant temperature treatment) for 0.5h ~10h.

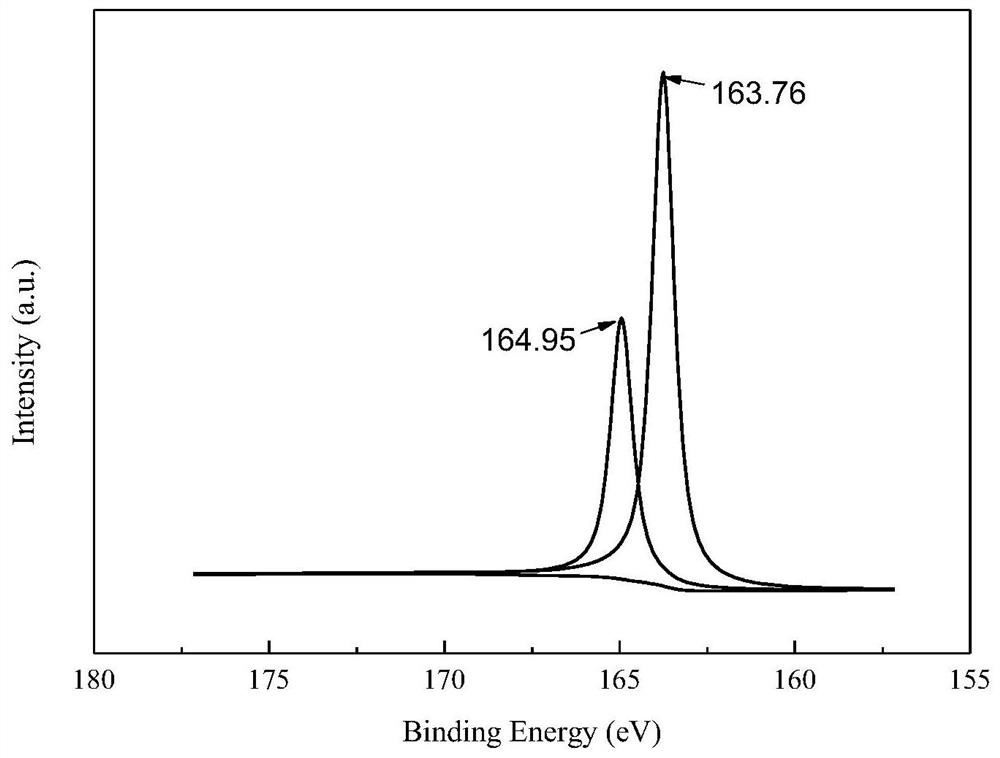

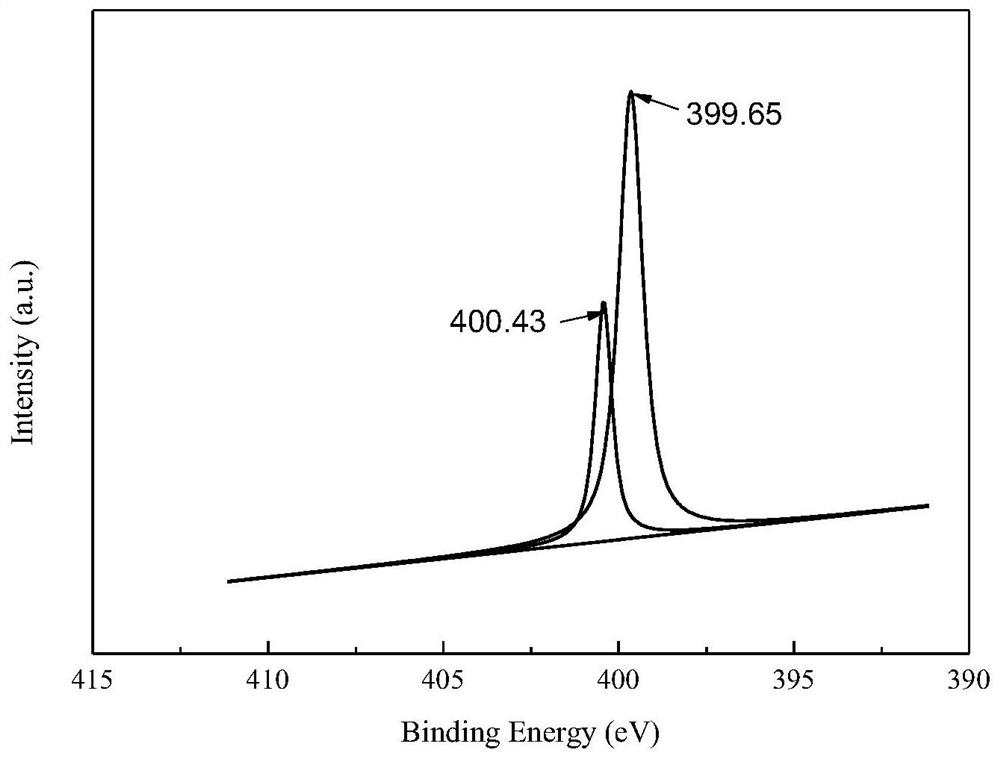

[0115] A carbon material doped only with thiophene-type sulfur and pyrrole-type nitrogen can be produced by using the above-mentioned embodiment.

[0116] According to the preparation method of sulfur-nitrogen doped carbon material of the present invention, in the operation of doping sulfur, one embodiment is to place the carbon material in a tube furnace, and feed the carrier gas containing thiophene at 8°C / min...

Embodiment 1

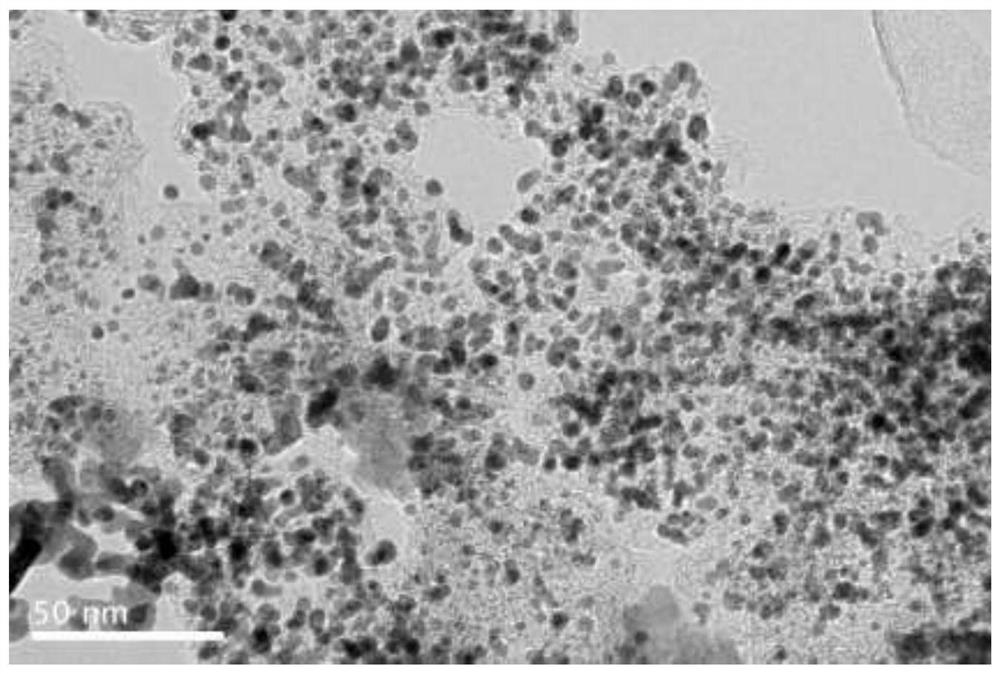

[0143] This example is used to illustrate the preparation of sulfur and nitrogen doped carbon materials and the preparation of platinum-carbon catalysts.

[0144] Immerse 1g of Vulcan XC72 in 20mL of 2wt% ammonia solution for 24 hours, dry it in an oven at 100°C and place it in a tube furnace. The carrier gas (nitrogen) enters the tube furnace after passing through a bubbler filled with thiophene. The temperature of the tube furnace was raised to 1200°C at a rate of 10°C / min, and then treated at a constant temperature for 3 hours. After natural cooling, a sulfur-nitrogen doped carbon material was obtained, which was designated as carbon support A. The quality of thiophene is based on the mass of sulfur contained in it, and the mass ratio of Vulcan XC72 to thiophene is 3:1. The amount of thiophene is controlled by the ventilation rate of the carrier gas, and the ventilation rate of the carrier gas corresponding to the different dosages of thiophene is calibrated in advance acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com