A method of fabricating a selectively doped structure

A selective, matrix technology, applied in the field of solar cells, can solve problems such as difficult mass production, large damage to silicon wafers, and surface concentration in lightly doped regions, so as to reduce surface recombination and emitter layer recombination, improve open circuit voltage and Short-circuit current, the effect of improving the quantum response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

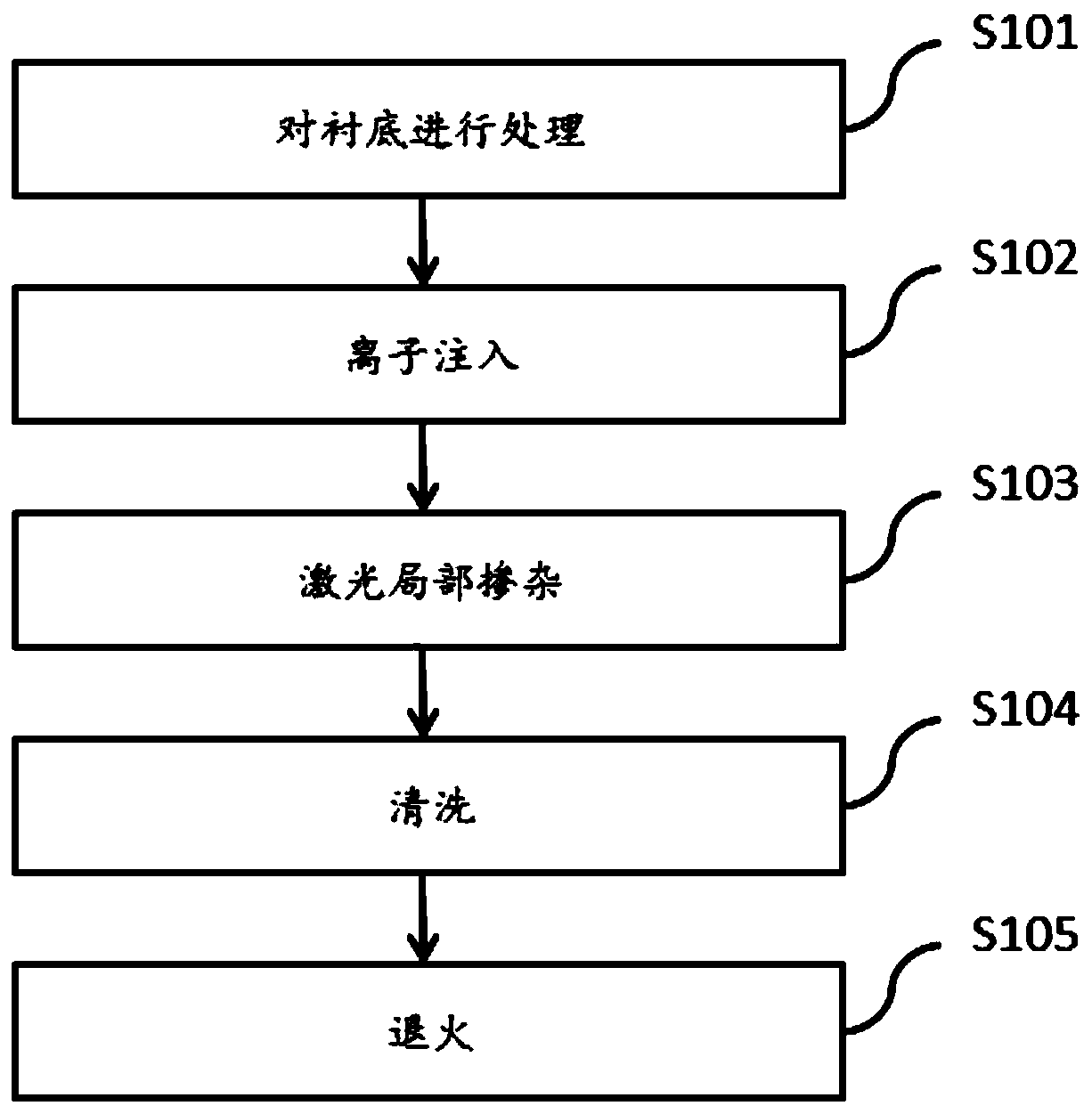

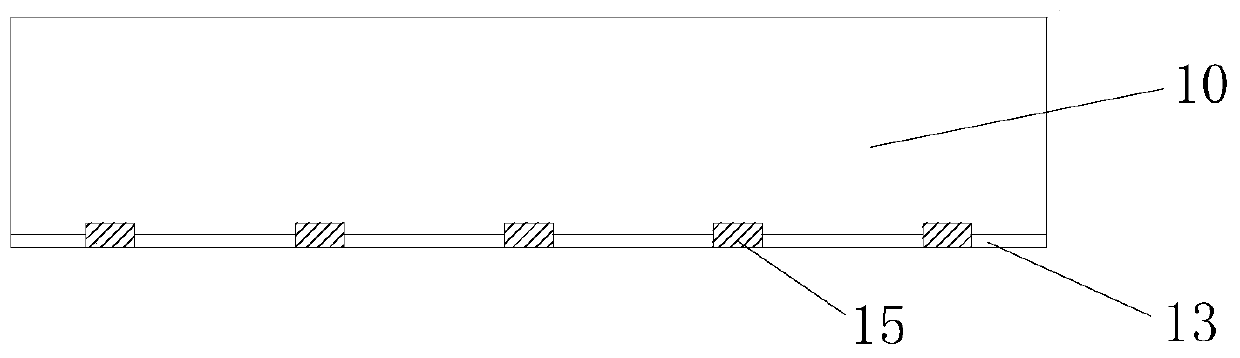

[0034] see Figure 1 to Figure 5 As shown, a method for fabricating a selectively doped structure provided in this embodiment includes the following steps:

[0035] S101. Select a P-type crystalline silicon substrate 10 of 156mm*156mm, and perform texturing and cleaning treatment on the surface of the P-type crystalline silicon substrate 10; the resistivity of the P-type crystalline silicon substrate 10 is 0.5-15Ω·cm, preferably 1~ 5Ω·cm; the thickness of the P-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm.

[0036] S102. Use an ion implanter to perform ion implantation on the front surface of the P-type crystalline silicon substrate 10 processed in step S101. The implanted element is phosphorus, and the implantation dose is 0.5×10 15 cm -2 ~3×10 15 cm -2 , preferably 1.5×10 15 cm -2 ~2.5×10 15 cm -2 . After the implantation is completed, a phosphorus-doped amorphous silicon layer 13 is formed on the front surface of the P-type crystalline s...

Embodiment 2

[0048] see Figure 1 to Figure 5 As shown, a method for fabricating a selectively doped structure provided in this embodiment includes the following steps:

[0049] S101. Select an N-type crystalline silicon substrate 10 of 156mm*156mm, and perform texturing and cleaning treatment on the surface of the N-type crystalline silicon substrate 10; the resistivity of the N-type crystalline silicon substrate 10 is 0.5-15Ω·cm, preferably 1- 5Ω·cm; the thickness of the N-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm.

[0050] S102. Use an ion implanter to perform ion implantation on the back surface of the N-type crystalline silicon substrate 10 processed in step S101. The implanted element is phosphorus, and the implantation dose is 0.5×10 15 cm -2 ~3×10 15 cm -2 , preferably 1.5×10 15 cm -2 ~2.5×10 15 cm -2 . After the implantation is completed, a phosphorus-doped amorphous silicon layer 13 is formed on the back surface of the N-type crystalline si...

Embodiment 3

[0054] see Figure 1 to Figure 5 As shown, a method for fabricating a selectively doped structure provided in this embodiment includes the following steps:

[0055] S101. Select an N-type crystalline silicon substrate 10 of 156mm*156mm, and perform texturing and cleaning treatment on the surface of the N-type crystalline silicon substrate 10; the resistivity of the N-type crystalline silicon substrate 10 is 0.5-15Ω·cm, preferably 1- 5Ω·cm; the thickness of the N-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm.

[0056] S102. Use an ion implanter to perform ion implantation on the front surface of the N-type crystalline silicon substrate 10 processed in step S101. The implanted element is boron, and the implantation dose is 0.5×10 15 cm -2 ~3×10 15 cm -2 , preferably 1.5×10 15 cm -2 ~2.5×10 15 cm -2 . After the implantation is completed, a boron-doped amorphous silicon layer 13 is formed on the back surface of the N-type crystalline silicon sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com