Ultrasonic-assisted method for preparing doped PbS quantum dot at low temperature in liquid phase

A low-temperature liquid phase, ultrasonic-assisted technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low doping amount, low reaction activity, long cooling time, etc., achieve uniform doping degree, shorten reaction time, speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of Cu-doped PbS quantum dots

[0042] 1. Under an argon atmosphere, weigh 0.36mmol of sulfur powder and place it in a test tube, add 0.36mL of dodecylamine to form solution A.

[0043] 2. Under an argon atmosphere, put 3.564mmol of lead chloride and 0.036mmol of copper acetylacetonate into a three-necked flask, and add 3.6mL of dodecylamine to form solution B.

[0044]3. Under an argon atmosphere, heat solution B to 150°C and pour solution A into solution B. After 200W ultrasonic reaction for 30 minutes, stop ultrasonication, and inject 5ml of cooling liquid ethylene glycol at the same time to stop the reaction.

[0045] 4. Mix the reaction product and ethanol at a volume ratio of 1:1, centrifuge at 1500rmp for 15 minutes, add ethanol at the same volume ratio, and repeat the centrifugation for 2-5 times to obtain the centrifuged product.

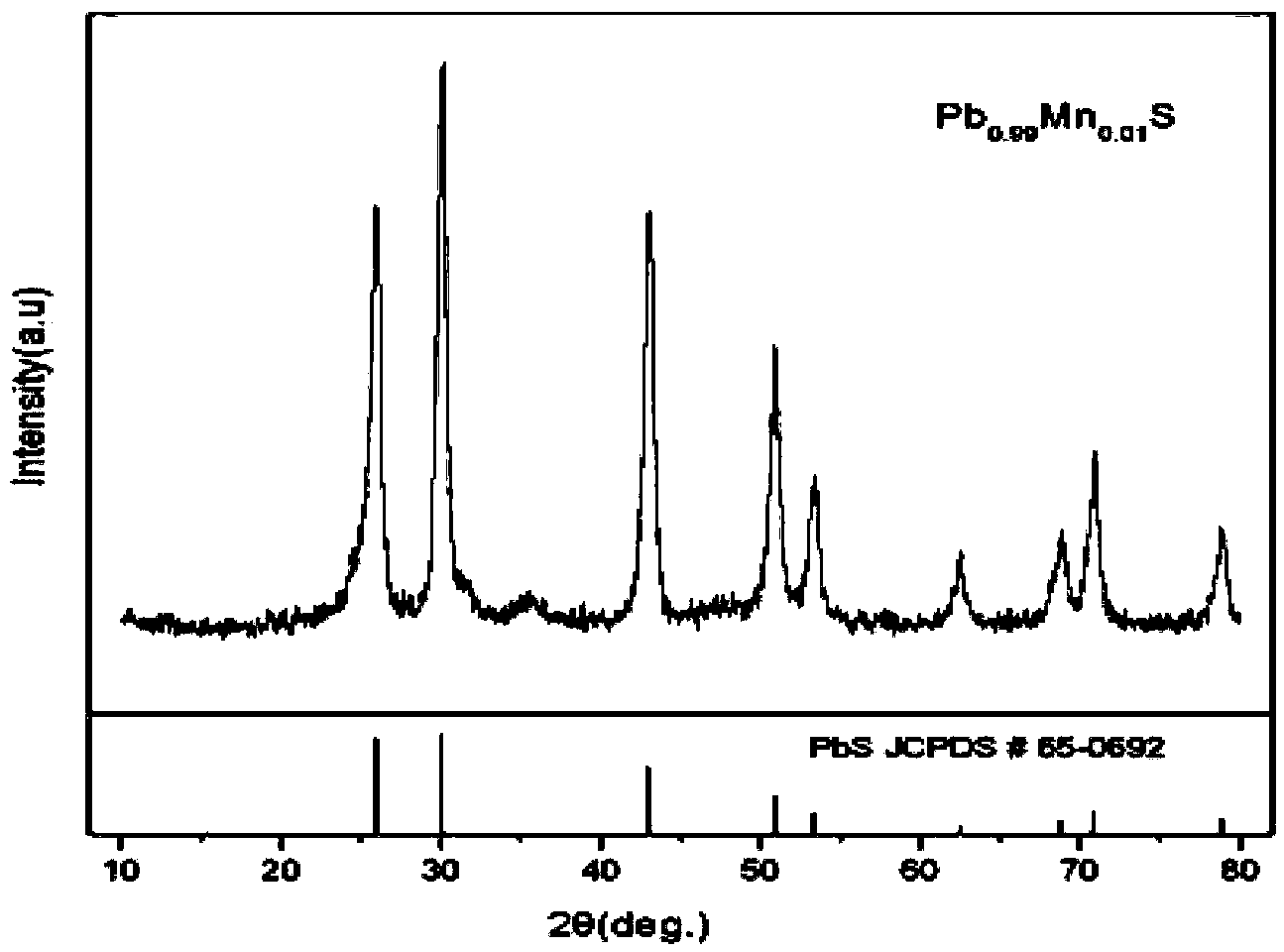

[0046] 5. Disperse the centrifuged product in octane at a concentration of 10 mg / ml to obtain Pb 0.99 Cu...

Embodiment 2

[0047] Embodiment 2: Preparation of W-doped PbS quantum dots

[0048] 1. Under a nitrogen atmosphere, weigh 36mmol of sodium sulfide and place it in a test tube, add 3.6mL of dodecene to form solution A.

[0049] 2. Under nitrogen atmosphere, put 1.8mmol lead chloride and 0.016mmol ammonium tungstate in a three-necked flask, add 0.36mL dodecene to make solution B.

[0050] 3. Under nitrogen atmosphere, after heating solution B to 300°C, pour solution A into solution B quickly, stop ultrasonication after 100W ultrasonic reaction for 60min, and inject 5ml of cooling liquid n-butanol at the same time to stop the reaction.

[0051] 4. Mix the reaction product with methanol at a volume ratio of 1:5, centrifuge at 5000rmp for 10 minutes, add methanol at the same volume ratio, and repeat the centrifugation for 2-5 times to obtain the centrifuged product.

[0052] 5. Disperse the centrifuged product in toluene at a concentration of 200 mg / ml to obtain Pb 0.9 W 0.1 S quantum dots. ...

Embodiment 3

[0053] Embodiment 3: Preparation of Zn-doped PbS quantum dots

[0054] 1. Under a helium atmosphere, weigh 1.8mmol thiourea and put it in a test tube, add 3.6mL octadecene to make solution A.

[0055] 2. Under a helium atmosphere, put 1.2mmol of lead acetylacetonate and 0.3mmol of zinc gluconate in a three-neck flask, add 3.6mL of octadecene to form solution B.

[0056] 3. In a helium atmosphere, heat solution B to 50°C and quickly pour solution A into solution B. After 300W ultrasonic reaction for 1 minute, stop ultrasonication, and inject 5ml of cooling liquid deionized water at the same time to stop the reaction.

[0057] 4. Mix the reaction product and isopropanol at a volume ratio of 1:10, centrifuge at 10,000 rpm for 5 minutes, add isopropanol at the same volume ratio, and repeat centrifugation for 2-5 times to obtain a centrifuged product.

[0058] 5. Disperse the centrifuged product in n-hexane at a concentration of 1 mg / ml to obtain Pb 0.9 Zn 0.1 S quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com