High-performance variable-valence metal ion oxide-containing microcrystalline glass electrode material as well as preparation method and application thereof

A technology of variable valence metal ions and glass-ceramics, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as not being able to meet the needs of high-power devices, improve negative electrode capacity and cycle stability, and shorten transmission distance , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

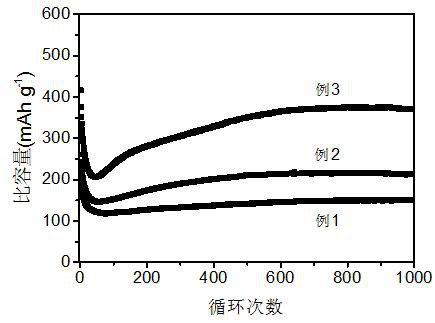

[0018] Example 1: A glass electrode material containing variable valence metal ion oxide and its preparation method

[0019] Weigh ferric oxide and ammonium dihydrogen phosphate, mix them evenly in a mortar, pour them into an alumina crucible, melt them in an air atmosphere, shape them, anneal them, cool them, and finally get a glass material; the melting temperature is 1250 °C, and the holding time is The annealing temperature was 20 min, the annealing temperature was 450 °C, and the annealing time was 2 h, and the glass electrode material (FeP sample) containing variable-valent metal ion oxide was obtained.

[0020] The obtained glass was ground into powder, and the sample powder, acetylene black and PVDF were put into a 50 mL ball mill jar at a speed of 400 r / min for 4 h at a mass ratio of 7:2:1 and 2 ml of N-methylpyrrolidone. , and then spread the paste on the copper foil. Dry under vacuum at 110 °C for 11 h, and after natural cooling, take out the electrode sheet cut in...

Embodiment 2

[0022] Example 2: A high-performance glass-ceramic electrode material containing variable-valence metal ion oxide and its preparation method

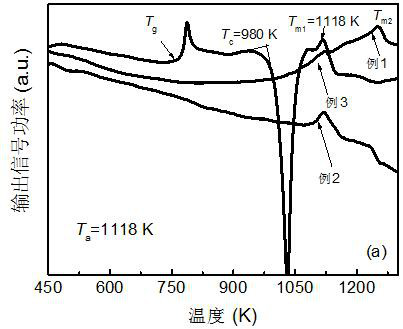

[0023] according to figure 1 According to the DSC curve of Example 1, the heat treatment temperature is selected, and the glass powder obtained in Example 1 is placed in an alumina ceramic state. powder. That is to obtain high-performance glass-ceramic electrode materials containing variable-valence metal ion oxides (A845-0.5h sample)

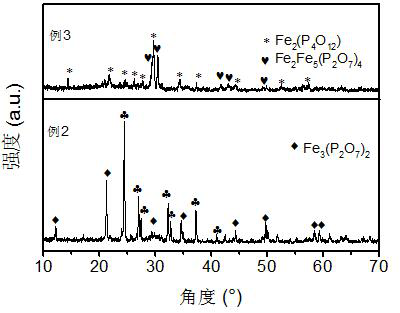

[0024] Detect the high-performance glass-ceramic electrode material containing variable-valence metal ion oxide obtained in embodiment 2, such as figure 2 It can be seen from the XRD pattern that the precipitated crystals are mainly Fe 3 (P 2 o 7 ) 2 .

[0025] Put the sample powder, acetylene black and PVDF in a mass ratio of 7:2:1 and 2ml of N-methylpyrrolidone into a 50mL ball mill jar for 4 h at a speed of 400 r / min, and then spread the slurry on the copper on foil. Dry under vacuum at 110 ...

Embodiment 3

[0027] Example 3: A high-performance glass-ceramic electrode material containing variable-valence metal ion oxide and its preparation method

[0028] according to figure 1 For the DSC curve of Example 1, the heat treatment temperature was selected. The glass powder obtained in Example 1 was placed in an atmosphere furnace. Under a reducing atmosphere, the heat treatment temperature was 845°C, kept for 0.5 h, cooled naturally to room temperature, and then taken out and ground into powder. That is to obtain high-performance glass-ceramic electrode materials containing variable-valence metal ion oxides (R845-0.5h sample)

[0029] Detect the high-performance glass-ceramic electrode material containing variable-valence metal ion oxide obtained in embodiment 3, such as figure 2 It can be seen from the XRD pattern that the precipitated crystals are mainly Fe 2 (P 4 o 12 ) and Fe 2 Fe 5 (P 2 o 7 ) 4 .

[0030] Put the sample powder, acetylene black and PVDF in a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com