Preparation method and manufacturing die of ITO tubular target material with large length-diameter ratio

A large aspect ratio, tubular technology, applied in the field of preparation of large aspect ratio ITO tubular targets, to achieve the effect of eliminating drastic changes in shrinkage rate, reducing sintered body deformation, and high-density sintered body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

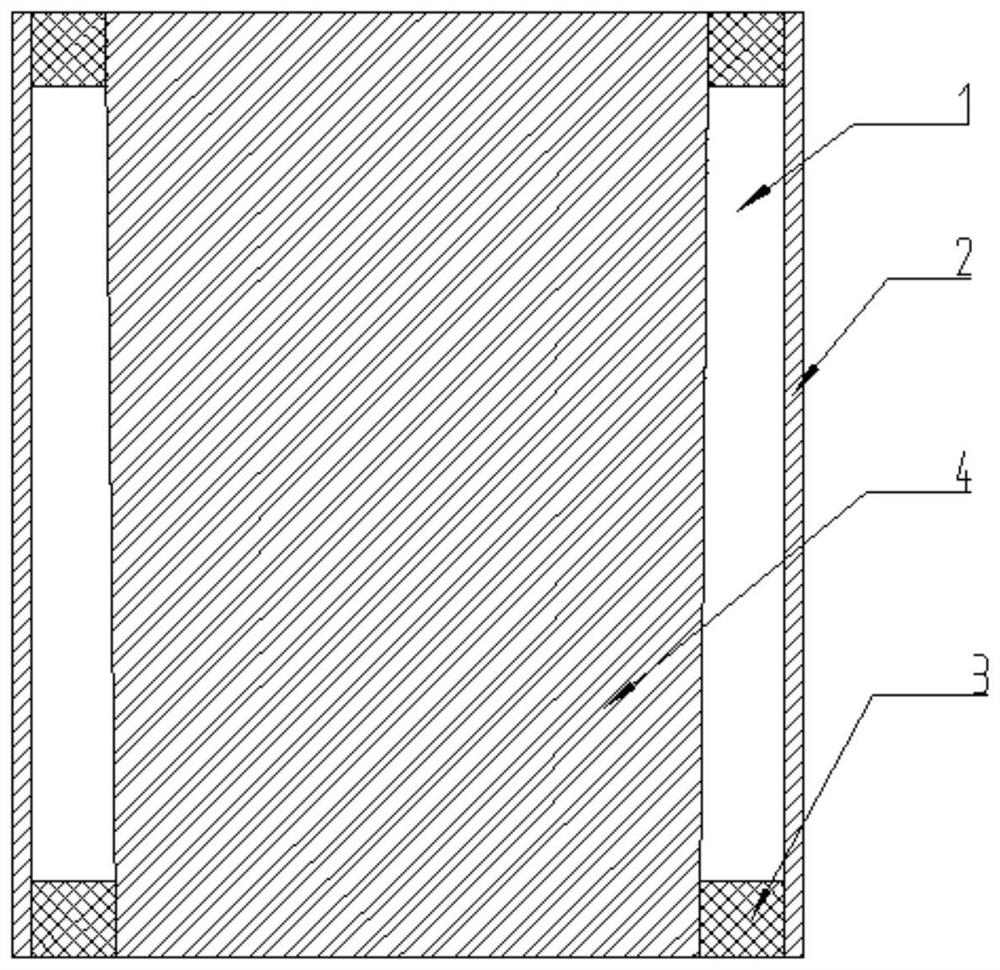

[0027] see figure 1 , the present invention provides a preparation method of a large aspect ratio ITO tubular target, comprising the following steps:

[0028] In step 1, the indium oxide powder and the tin oxide powder are uniformly mixed by a V-type mixer, a three-dimensional mixer and other equipment according to a weight percentage of 90:10;

[0029] Step 2, roasting the mixed powder to form ITO mixed powder;

[0030] Step 3: Use deionized water with electrical conductivity ≥10MΩ as the dispersion medium for the ITO mixed powder, add polyacrylate ammonium as the dispersant, PVA polyvinyl alcohol as the binder, and use Φ3-5mm yttrium-stabilized zirconia balls as the dispersion medium. Grinding medium, ball mill 20-60hr;

[0031] In step 4, the ITO mixed powder treated in step 3 is subjected to agglomeration and granulation, and the tap density of the granulated ITO powder is 2.0-3.5g / cm3, and the moisture content is 0.5-2.5%;

[0032] Step 5: Load the agglomerated and gra...

Embodiment 1

[0042] Embodiment 1, a preparation method of a large aspect ratio ITO tubular target, comprising the following steps:

[0043] Step 1, mix the indium oxide powder with a specific surface area of 22.5m2 / g and the tin oxide powder with a specific surface area of 11m2 / g according to a ratio of 90:10 (wt%), and use a three-dimensional mixer to mix for 12hr;

[0044] Step 2, calcining the mixed powder at 1250° C. under an oxygen atmosphere for 3.5 hr to obtain an ITO mixed powder with a specific surface area of 5.5 m2 / g;

[0045] Step 3: Use deionized water with electrical conductivity ≥ 10MΩ as the dispersion medium for the ITO mixed powder, add polypropylene ammonium as the dispersant, PVA polyvinyl alcohol as the binder, and use Φ5mm yttrium-stabilized zirconia balls as the grinding medium , ball mill 60hr;

[0046] In step 4, the ball-milled ITO mixed powder is subjected to agglomeration and granulation, and the tap density of the granulated ITO powder is 2.75g / cm3 and t...

Embodiment 2

[0050] Embodiment 2, a preparation method of a large aspect ratio ITO tubular target, comprising the following steps:

[0051] Step 1, mix the indium oxide powder with a specific surface area of 22.5m2 / g and the tin oxide powder with a specific surface area of 11m2 / g according to the ratio of 90:10 (wt%), and use a three-dimensional mixer to mix for 12hr

[0052] Step 2, calcining the mixed powder at 1050° C. under an oxygen atmosphere for 3.5 hr to obtain an ITO mixed powder with a specific surface area of 7.6 m2 / g;

[0053] Step 3: Use deionized water with electrical conductivity ≥ 10MΩ as the dispersion medium for the ITO mixed powder, add polypropylene ammonium as the dispersant, PVA polyvinyl alcohol as the binder, and use Φ5mm yttrium-stabilized zirconia balls as the grinding medium , ball mill 60hr;

[0054] In step 4, the ball-milled ITO mixed powder is agglomerated and granulated, and the tap density of the granulated ITO powder is 2.3 g / cm 3 and the moisture c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com