Magnetic inorganic nanoparticle and ordered mesoporous material core-shell composite material and preparation method thereof

A technology of inorganic nanoparticles and mesoporous materials, which is applied in inorganic chemistry, chemical instruments and methods, and other chemical processes, etc., can solve the problems of poor universality of preparation methods, complex synthesis steps and disorder, and achieve simple and sensitive steps. Magnetic Response Characteristics, Effects of Large Apertures and Pore Volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a preparation method of magnetic inorganic nanoparticles@ordered mesoporous material core-shell composite material, comprising the following steps:

[0040](1) dissolving the surfactant, the shell precursor and the catalyst in an organic solvent to obtain a mixed solution;

[0041] (2) drying the mixed solution obtained in step (1) to obtain a single micelle gel;

[0042] (3) The single micelle gel obtained in step (2) is mixed with magnetic inorganic nanoparticles, organic alcohols and water and then reacted. The reaction product is washed, dried and calcined at high temperature to obtain magnetic inorganic nanoparticles@ordered mesoporous material core-shell composite materials;

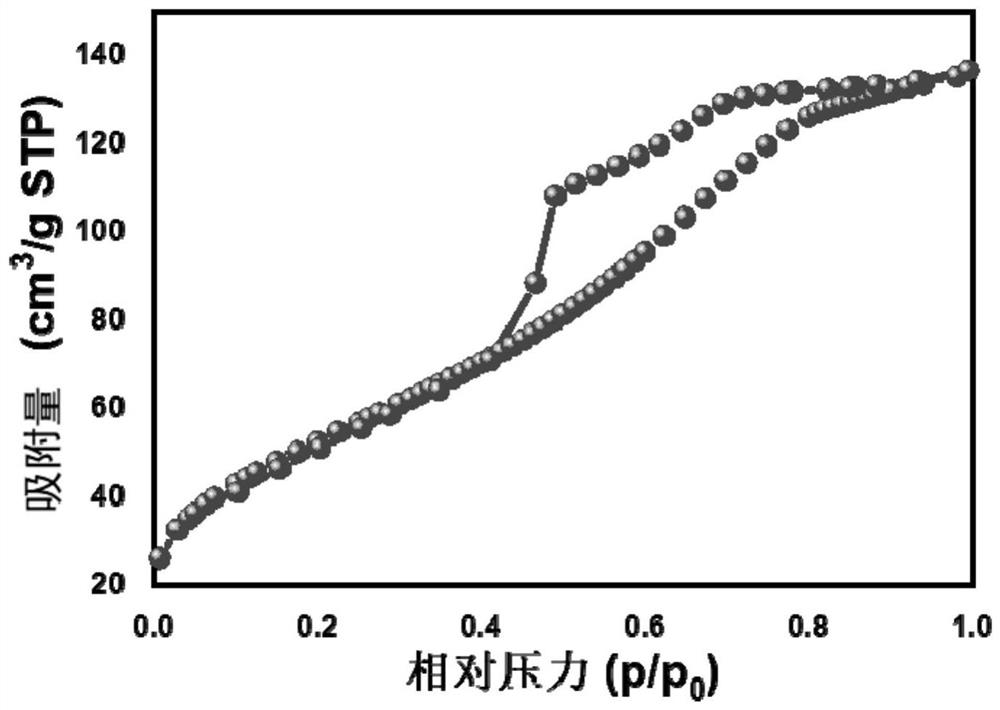

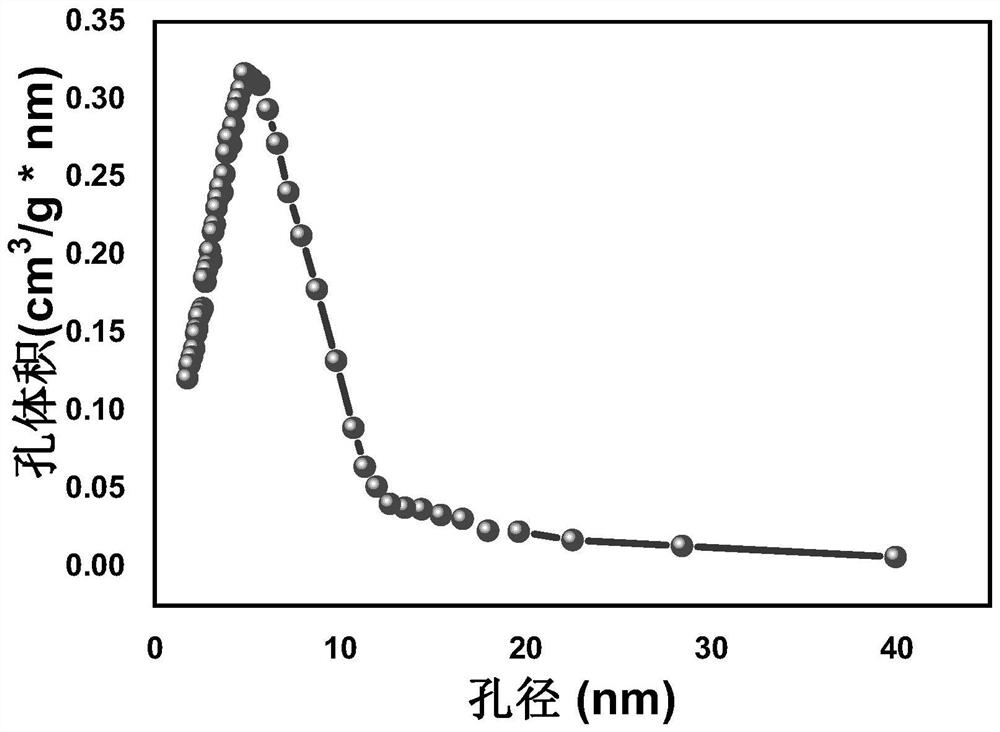

[0043] Among them, the specific surface area of magnetic inorganic nanoparticles@ordered mesoporous material core-shell composite material is 50-1200m 2 / g, the mesopore size is 2-40nm, and the mesoporous shell thickness is 5-100nm;

[0044] The ordered me...

Embodiment 1

[0065] This example provides a γ-ferric oxide particle@mesoporous titanium dioxide composite material and its preparation method.

[0066] Mix 0.1mmol F127 (surfactant), 30mL tetrahydrofuran and 2.4mmol concentrated hydrochloric acid (36-38wt%), stir at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then add 1mmol tetrabutyl titanate, and continue stirring for one hours; the mixed solution was transferred to a constant temperature drying oven, and placed at 40°C for 48h to obtain a white single micelle gel;

[0067] Disperse 1.0g of single micellar gel and 100mg of γ-iron sesquioxide particles in a mixed solution of 30mL of ethanol and 100mL of water, and then heat at 70°C for 12h; The surface active agent was removed by roasting at 500°C for 3 hours, and the γ-Fe2O3 particles@mesoporous titanium dioxide composite material was obtained.

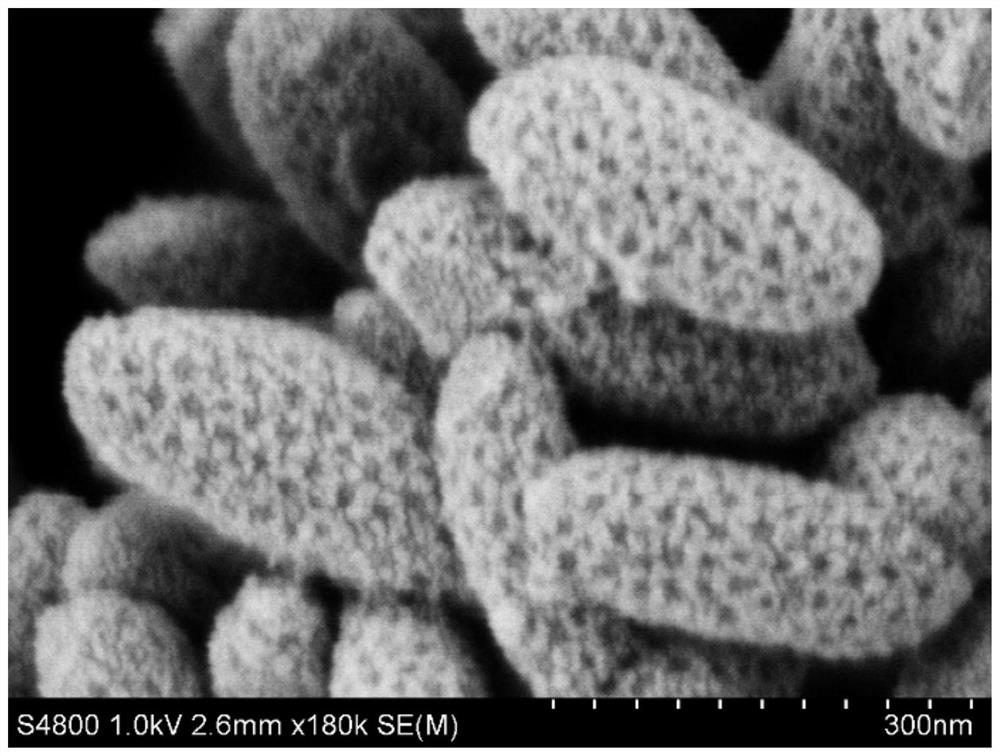

[0068] figure 1 The scanning electron micrograph shows that the γ-ferric oxide particles@mesoporous tit...

Embodiment 2

[0073] This example provides a γ-ferric oxide particle@mesoporous titanium dioxide composite material and its preparation method.

[0074] Mix 0.1mmol F127 (surfactant), 30mL tetrahydrofuran and 2.4mmol concentrated hydrochloric acid (36-38wt%), stir at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then add 1mmol tetrabutyl titanate, and continue stirring for one hours; the mixed solution was transferred to a constant temperature drying oven, and placed at 40°C for 48h to obtain a white single micelle gel;

[0075] Disperse 2.0g of single micellar gel and 100mg of γ-iron sesquioxide particles in a mixed solution of 30mL of ethanol and 100mL of water, then heat at 70°C for 12h; Roast at 500°C for 3 hours to remove the surfactant, and obtain a shell with a thickness of 30nm, a pore diameter of 8.0nm, and a specific surface area of 220m 2 / g, γ-Fe2O3 particles@mesoporous titania composites with space group P6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com