Composite ceramic coated fiber diaphragm, preparation method thereof and lithium battery

A composite ceramic and coating technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of low melting point of the separator, battery failure, explosion, etc., and improve the liquid retention capacity , low self-discharge, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

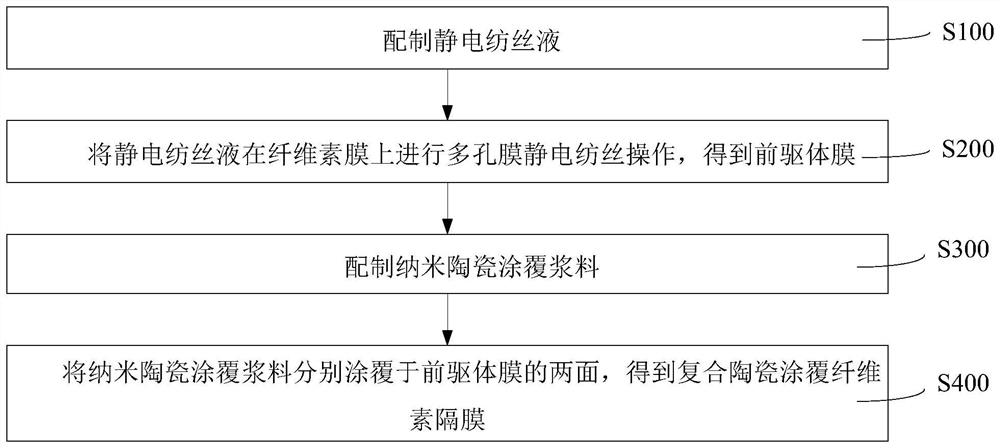

[0031] The application provides a method for preparing a composite ceramic coated fiber diaphragm. The preparation method of the above-mentioned composite ceramic coated fiber membrane comprises the following steps: preparing an electrospinning solution; performing a porous membrane electrospinning operation on the electrospinning solution on a cellulose membrane to obtain a precursor film; preparing a nano-ceramic coating Slurry: coating the nano-ceramic coating slurry on both sides of the precursor film respectively to obtain the composite ceramic-coated cellulose diaphragm.

[0032] In the preparation method of the above-mentioned composite ceramic coated fiber diaphragm, by preparing the electrospinning liquid, then performing the electrospinning operation of the porous membrane on the electrospinning liquid on the cellulose membrane, the cellulose film is used as the base film of the composite diaphragm, which can The composite diaphragm has good stability, and the cellul...

Embodiment 1

[0063] The membrane component materials in preset proportions are sequentially added into the organic solvent, and stirred and mixed to obtain an electrospinning solution. Then, the electrospinning liquid was electrospun on the cellulose membrane to form a porous membrane layer, wherein the thickness of the cellulose membrane was 5 μm, and the porosity was 40%. Weigh a preset amount of nano-ceramic component materials, dissolve them in deionized water, and perform a high-speed dispersion operation to obtain a uniform nano-ceramic coating slurry, wherein the nano-ceramic coating slurry includes 10 wt% of particles with a diameter of 0.1 μm Aluminum oxide, 0.5wt% binder, 0.1wt% stabilizer and 0.2wt% surfactant. The nano-ceramic coating slurry is coated on both sides of the precursor film respectively to obtain a composite ceramic-coated cellulose diaphragm.

Embodiment 2

[0065] The membrane component materials in preset proportions are sequentially added into the organic solvent, and stirred and mixed to obtain an electrospinning solution. Then, the electrospinning liquid is subjected to electrospinning operation of the porous membrane on the cellulose membrane to form a porous membrane layer, wherein the thickness of the cellulose membrane is 20 μm, and the porosity is 90%. Weigh a preset amount of nano-ceramic component materials, dissolve them in deionized water, and perform a high-speed dispersion operation to obtain a uniform nano-ceramic coating slurry, wherein the nano-ceramic coating slurry includes 30 wt% of oxide particles with a diameter of 5 μm Aluminum, 10wt% binder, 2wt% stabilizer and 1wt% surfactant. The nano-ceramic coating slurry is coated on both sides of the precursor film respectively to obtain a composite ceramic-coated cellulose diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com