Binder and battery containing same

A binder and polymer technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as irreversible mechanical degradation and delamination, achieve good toughness and self-healing ability, buffer deformation, and improve cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

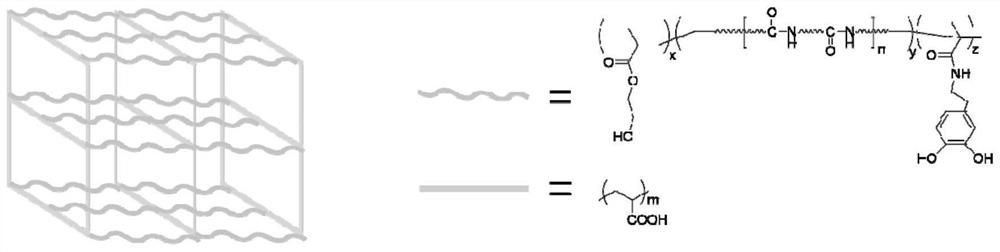

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides the preparation method of above-mentioned adhesive, and described preparation method comprises the following steps:

[0060] Step 1: preparing terminal alkenyl polyurethane;

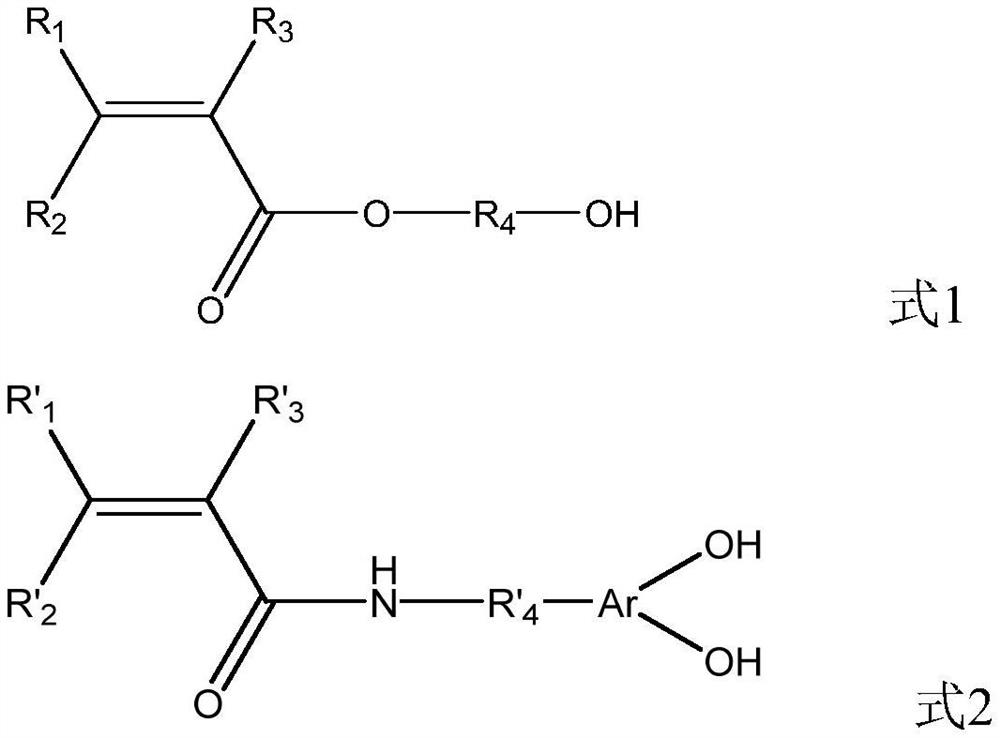

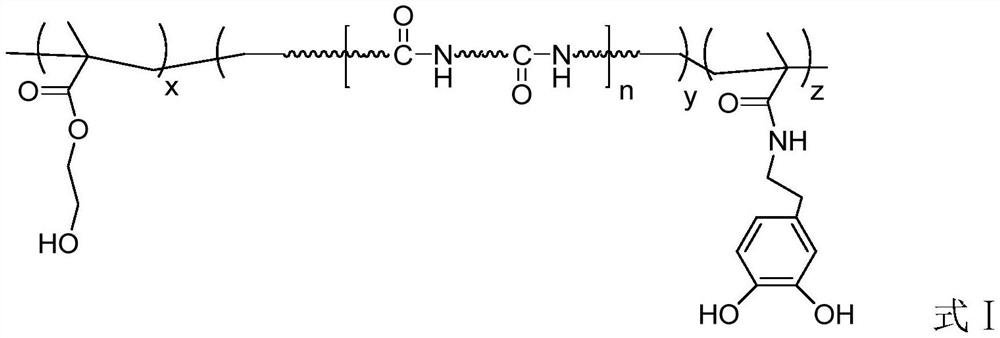

[0061] Step 2: Free radical polymerization of alkenyl-terminated polyurethane, a monomer having the chemical formula shown in Formula 1, and a monomer having the chemical formula shown in Formula 2, to obtain the second polymer;

[0062] Step 3: mixing the second polymer with the first polymer to obtain the binder.

[0063] According to an embodiment of the present invention, in step 1, the polyurethane prepolymer is prepared by reacting polyester polyol and / or polyether polyol with polyisocyanate, and then reacting with a hydroxyl-terminated double bond monomer to prepare the terminal Alkenyl polyurethane.

[0064] According to the embodiment of the present invention, Step 1 is specifically: 50-70 parts by weight of polyester polyol and / or polyether polyol, h...

Embodiment 1

[0097] The preparation method of this implementation self-healing adhesive is as follows:

[0098] (1) Add 0.1 mol (200 g) of polycaprolactone diol with a number average molecular weight of 2000 to a three-neck flask equipped with a stirrer, a spherical condenser and a constant pressure dropping funnel, and heat up to 120° C. for vacuum dehydration for 3 h. After cooling down to 40°C, add 0.15mol (25.2g) of hexamethylene diisocyanate (HDI), drop HDI into the system through a constant pressure dropping funnel, slowly raise the temperature to 80°C after the addition, add the above two monomers The 0.5% mass fraction catalyst dibutyltin dilaurate (DBTDL) of the mass summation, reaction 6h, add terminal hydroxyl double bond monomer hydroxyethyl methacrylate (HEMA) 0.1mol (13.1g) capping reaction 12h, after cooling The polycaprolactone type polyurethane prepolymer can be obtained by adding 200 g of solvent DMF to dilute and discharge the material. It can be seen from tests that its...

Embodiment 2

[0119] The self-healing adhesive preparation method of the present embodiment is as follows:

[0120] (1) Add 0.1 mol (200 g) of polycarbonate diol with a number average molecular weight of 2000 to a three-necked flask equipped with a stirrer, a spherical condenser and a constant pressure dropping funnel, heat up to 120° C. for vacuum dehydration for 3 hours, and cool down After reaching 40°C, add 0.15mol (25.2g) of hexamethylene diisocyanate (HDI), drop HDI into the system through a constant pressure dropping funnel, slowly raise the temperature to 80°C after the addition, add the total of the above two monomers 0.5% mass fraction of the mass catalyst dibutyltin dilaurate (DBTDL), react for 6h, add 0.1mol (13.1g) of hydroxyl-terminated double bond monomer hydroxyethyl methacrylate (HEMA) for capping reaction for 12h, add solvent after cooling 200g of DMF is diluted and discharged to obtain a polycarbonate polyurethane prepolymer, the number average molecular weight of which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com