Copper ion doped calcium silicate microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and calcium silicate, which is applied in the field of electronic ceramic materials, can solve the problems of unsatisfactory quality factor of CaSiO ceramics, difficulty in achieving low-temperature co-firing, high sintering temperature, etc., and achieve excellent microwave dielectric properties, high density, Effect of Improving Dielectric Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of copper ion-doped calcium silicate microwave dielectric ceramics, comprising the following steps:

[0036] According to the stoichiometric ratio of calcium, copper and silicon in formula I, CaCO 3 , SiO 2 and CuO are mixed, and the resulting mixture is first ball milled to obtain the first ball mill;

[0037] Ca 1-x Cu x SiO 3 Formula I; In formula I: 0

[0038] Grinding and calcining the first ball mill material in sequence, and subjecting the obtained calcined powder to second ball milling to obtain Ca 1- x Cu x SiO 3 Powder;

[0039] the Ca 1-x Cu x SiO 3 After the powder and the binder are mixed, they are successively granulated, sieved and pressed to obtain a ceramic green body;

[0040] The ceramic green body is sintered to obtain copper ion-doped calcium silicate microwave dielectric ceramics; the sintering temperature is above 1050°C.

[0041] The present invention according to the stoichiomet...

Embodiment 1

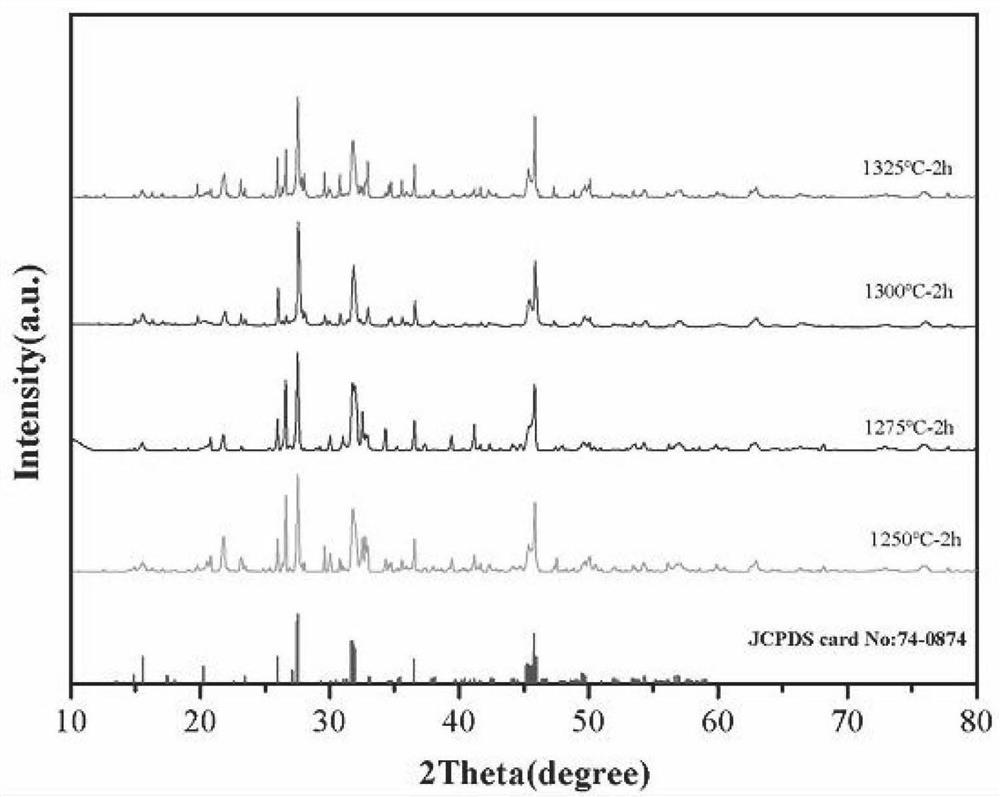

[0056] Calcined at 1250 °C, 1275 °C, 1300 °C and 1325 °C for 2 h to synthesize CaSiO 3 Powder.

[0057] By compound CaSiO 3 The stoichiometric ratio of each element, weigh the raw material CaCO 3 50g, SiO 2 30g, put the weighed raw materials into the ball mill jar after mixing for 40min with a three-dimensional mixer, and carry out the first ball milling, with deionized water as the dispersant, and the ball milling medium as zirconia balls, zirconia balls and powder, The mass ratio of deionized water is 3:1:1, the ball milling speed is 300r / min, and the ball milling time is 4h. After the ball milling, the obtained mixed powder was dried in an oven at 80° C. for 15 hours to remove moisture, and after drying, the mixed powder was ground in an agate mortar and evenly ground. The uniformly ground powder was calcined in a box furnace for 2 hours (calcination temperatures were 1250°C, 1275°C, 1300°C and 1325°C, respectively), and the heating rate was 5°C / min. The obtained cal...

Embodiment 2

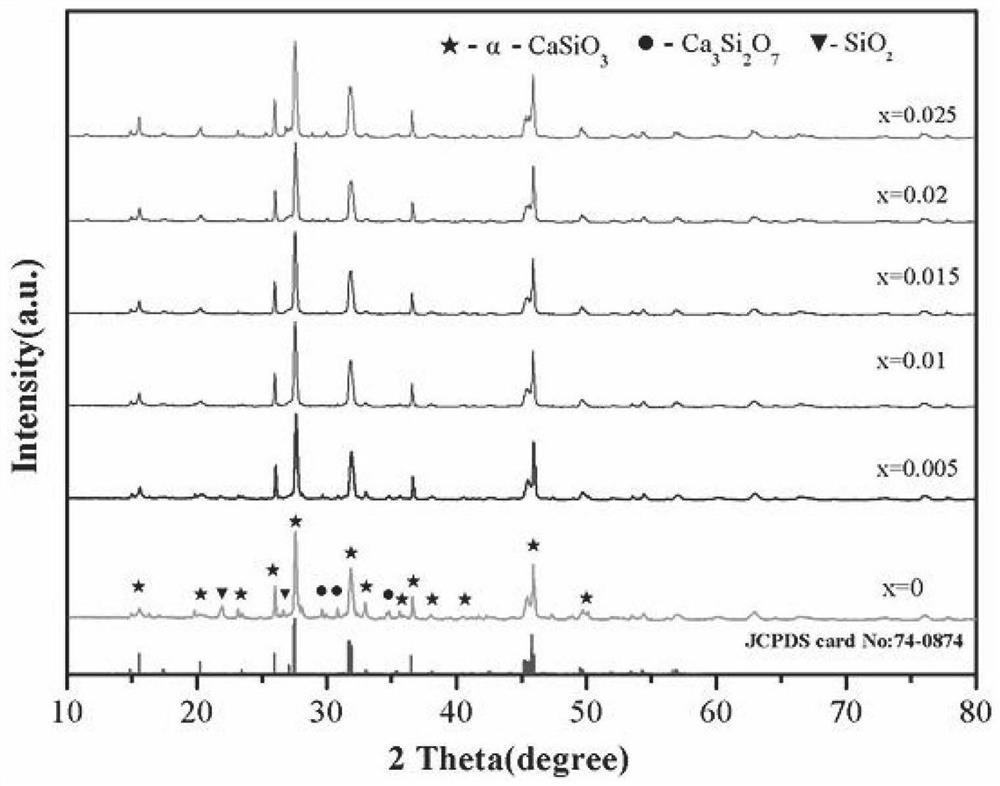

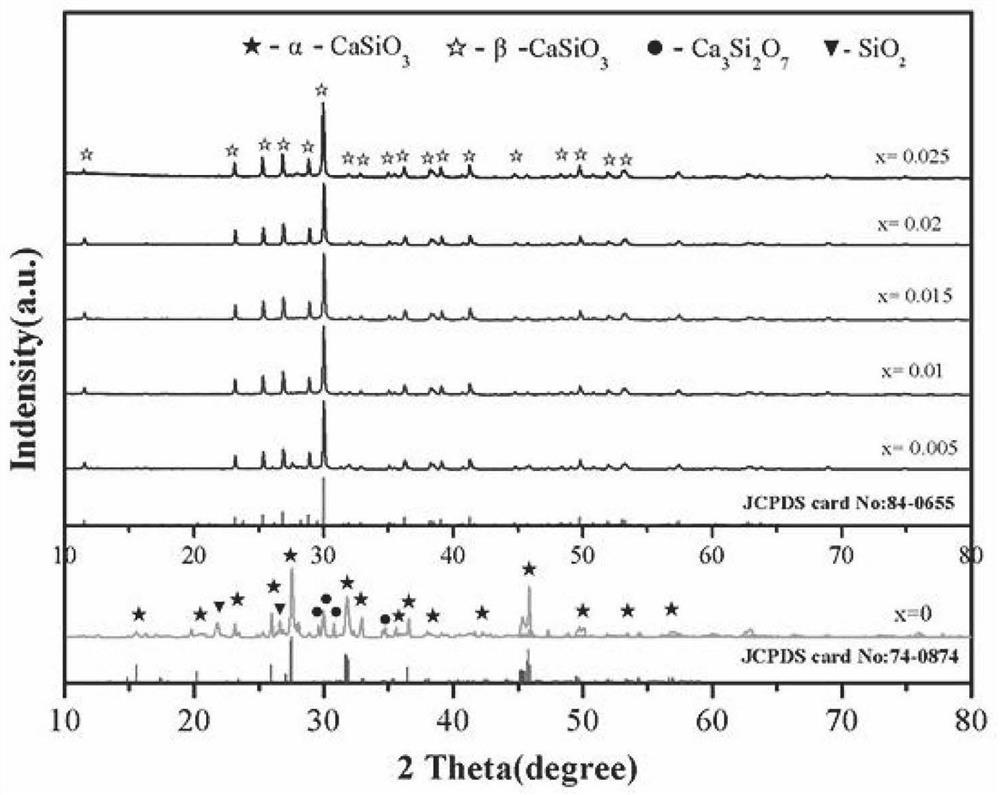

[0059] Calcined at 1300°C for 2h to synthesize Ca 1-x Cu x SiO 3 Powder (x=0.005, 0.01, 0.015, 0.020 or 0.025):

[0060] by compound Ca 1-x Cu x SiO 3 The stoichiometric ratio of each element weighs the raw material CaCO 3 , SiO 2 and CuO, mix the weighed raw materials with a three-dimensional mixer for 40 minutes, then put them into a ball mill tank for the first ball mill, use deionized water as the dispersant, and the ball mill medium is zirconia balls, zirconia balls and powder 1. The mass ratio of deionized water is 3:1:1, the ball milling speed is 300r / min, and the ball milling time is 4h. After the ball milling, the obtained mixed powder was dried in an oven at 80° C. for 15 hours to remove moisture, and after drying, the mixed powder was ground in an agate mortar and evenly ground. The uniformly ground powder was calcined in a box furnace at 1300 °C for 2 h with a heating rate of 5 °C / min. The obtained calcined powder is subjected to the second ball milling, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com