Silicon-based ecological functional polyurethane composite material and preparation method thereof

An ecological function and composite material technology, applied in the direction of textiles and paper making, can solve the problems of surface touch, light resistance, aging resistance, hydrophobic and anti-fouling properties of polyurethane materials, and achieve excellent surface heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

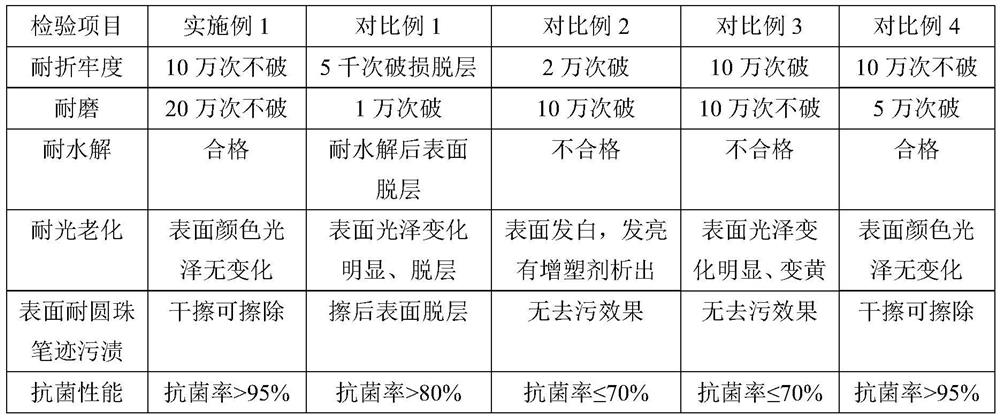

Examples

Embodiment 1

[0028] A preparation method of a silicon-based ecological functional polyurethane composite material, comprising the following steps:

[0029] (1) First, use a pipeline static mixer to mix the silicone resin material A and the silicone resin B material at a mass ratio of 1:1 to obtain a vinyl poss modified silicone resin containing reactive functional groups; Scrape poss modified silicone resin with a thickness of 15 wires on the surface of the release paper and dry it. The oven temperature is 130°C and the drying time is 8 minutes to form a surface layer of silicone resin;

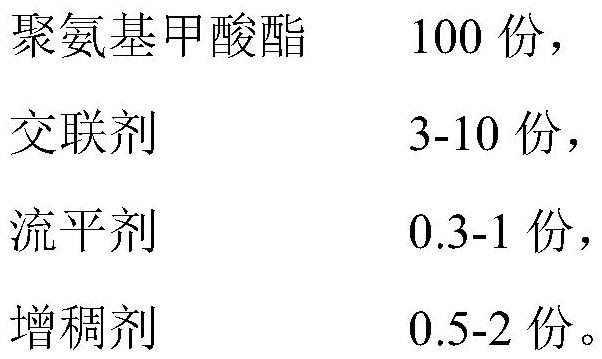

[0030] (2) Scrape 25 strands of water-based PU interlayer slurry on the surface of the silicone resin surface layer that can react with it, and set a gradient temperature difference in the oven: bake at 80°C for 1 minute, bake at 100°C for 2 minutes, and bake for 3 minutes to form Water-based PU middle layer; by mass parts, the water-based PU middle layer slurry includes the following components:

[0031...

Embodiment 2

[0040] A preparation method of a silicon-based ecological functional polyurethane composite material, comprising the following steps:

[0041] (1) First, use a pipeline static mixer to mix the silicone resin material A and the silicone resin B material at a mass ratio of 1:1 to obtain a vinyl poss modified silicone resin containing reactive functional groups; Scrape the poss modified silicone resin with a thickness of 10 wires on the surface of the release paper and dry it. The oven temperature is 100°C and the drying time is 3 minutes to form a silicone resin surface layer;

[0042] (2) Scrape 30 wires of water-based PU interlayer slurry that can react with it on the surface of the silicone resin surface layer. The oven is set with a gradient temperature difference of 80°C for 30s, 130°C for 4.5 minutes, and the drying time is 5 minutes to form water-based PU. Intermediate layer; by mass parts, the water-based PU intermediate layer slurry includes the following components:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com