Preparation method of modified hemp fiber reinforcing material for auto ceiling

A technology for automotive roofs and reinforcing materials, which is applied in the field of automotive interior composite materials, can solve problems such as complex processes, high costs, and uneven mixing, and achieve simple and easy preparation processes, high toughness, impact resistance, and comprehensive performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

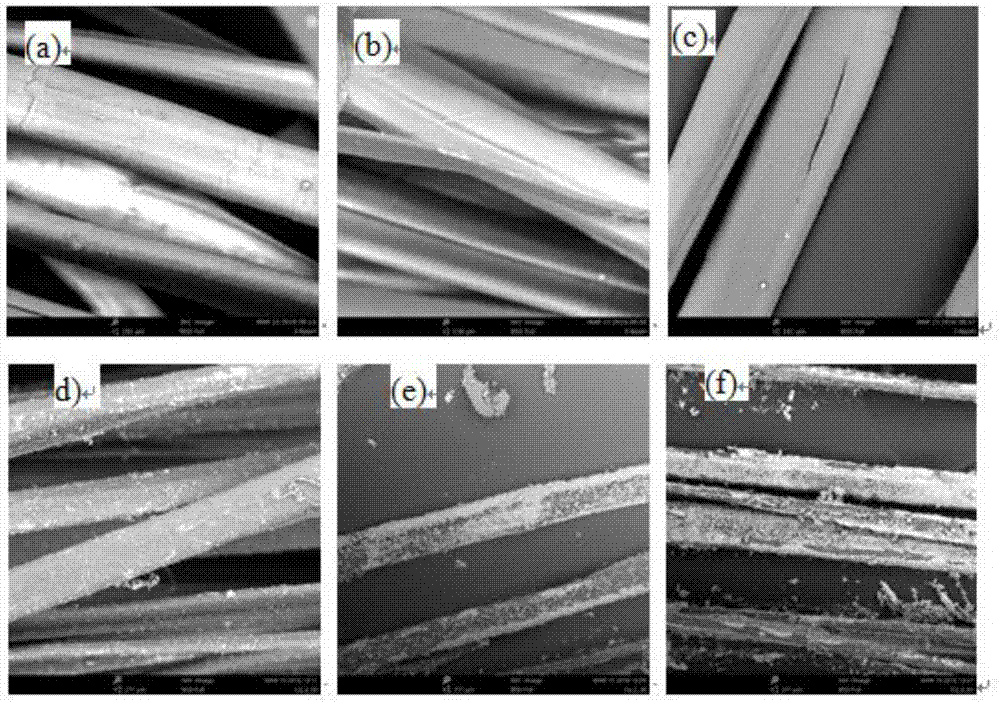

[0031] see Figure 1-3 As shown, the technical solution adopted in the present invention is: a modified hemp fiber reinforced material for automobile roof and its preparation method, wherein the modified hemp fiber reinforced material for automobile roof is made of the following raw materials in parts by weight: ramie fiber 72 16 parts of anhydrous calcium chloride, 18 parts of anhydrous sodium carbonate, 15 parts of sodium hydroxide, 4 parts of acetic acid, 26 parts of ethanol, 19 parts of magnesium acetate tetrahydrate, 9 parts of disodium edetate and JFC permeate 12 doses.

[0032] Further, the preparation method of the modified hemp fiber reinforced material for the automobile roof comprises the following specific steps:

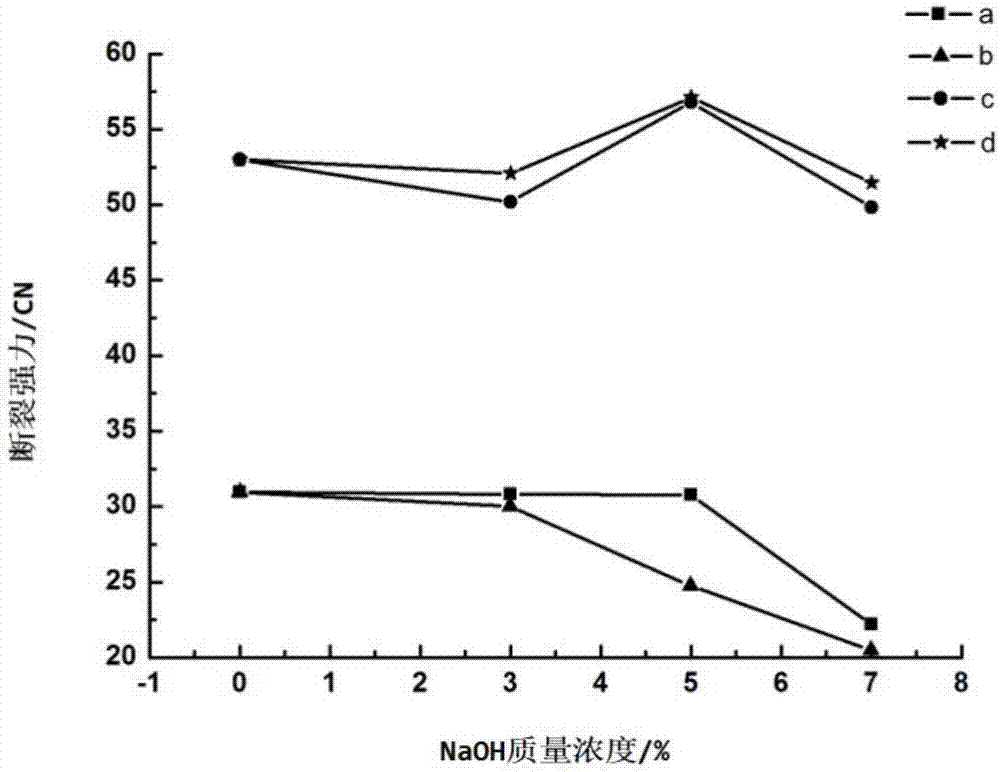

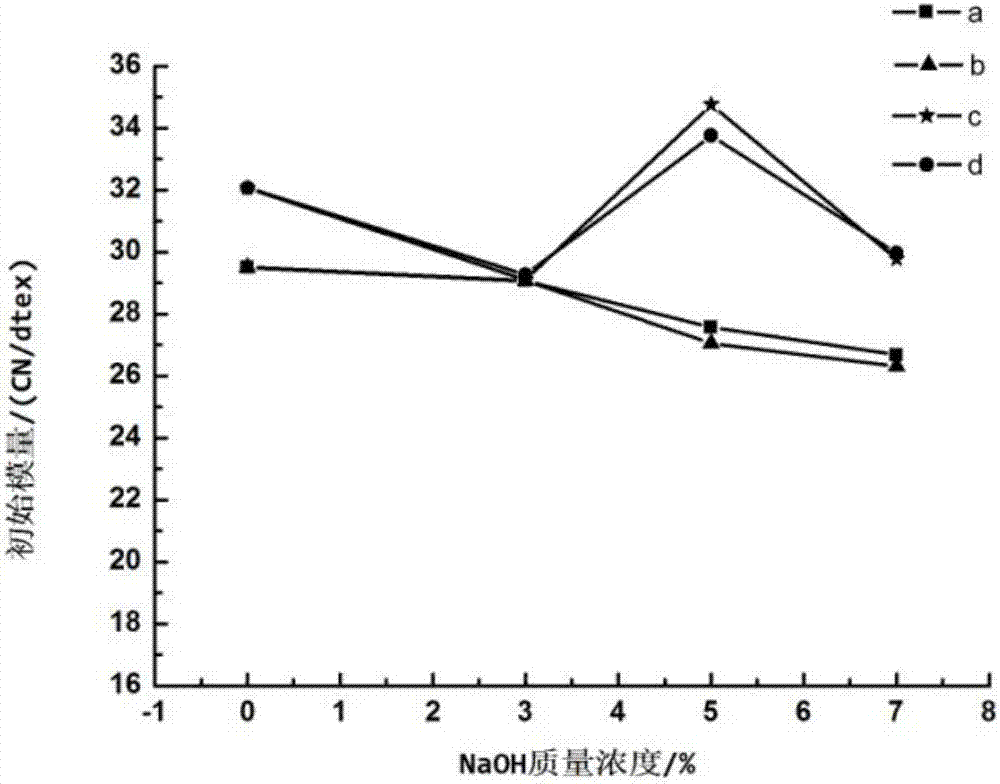

[0033] 1). Immerse the degummed ramie fibers in an aqueous solution of 15 parts by weight of sodium hydroxide at a bath ratio of 1:150, soak for 2 hours in a water bath at 50°C, place the reactor in an ultrasonic cleaner, and The alkaline-treated ramie...

Embodiment 2

[0037] see Figure 1-3 As shown, the technical solution adopted in the present invention is: a modified hemp fiber reinforced material for automobile roof and its preparation method, wherein the modified hemp fiber reinforced material for automobile roof is made of the following raw materials in parts by weight: ramie fiber 75 , 21 parts of anhydrous calcium chloride, 20 parts of anhydrous sodium carbonate, 21 parts of sodium hydroxide, 6 parts of acetic acid, 30 parts of ethanol, 25 parts of magnesium acetate tetrahydrate, 10 parts of disodium edetate and JFC permeate 15 doses.

[0038] Further, the preparation method of the modified hemp fiber reinforced material for the automobile roof comprises the following specific steps:

[0039] 1). Immerse the degummed ramie fibers in an aqueous solution of 21 parts by weight of sodium hydroxide at a bath ratio of 1:150. After soaking in a water bath at 60°C for 3 hours, place the reactor in an ultrasonic cleaner. The alkaline-treat...

Embodiment 3

[0043] see Figure 1-3As shown, the technical solution adopted in the present invention is: a modified hemp fiber reinforced material for automobile roof and its preparation method, wherein the modified hemp fiber reinforced material for automobile roof is made of the following raw materials in parts by weight: ramie fiber 70 16 parts of anhydrous calcium chloride, 16 parts of anhydrous sodium carbonate, 14 parts of sodium hydroxide, 2 parts of acetic acid, 24 parts of ethanol, 17 parts of magnesium acetate tetrahydrate, 9 parts of disodium edetate and JFC permeate 10 doses.

[0044] Further, the preparation method of the modified hemp fiber reinforced material for the automobile roof comprises the following specific steps:

[0045] 1). Immerse the degummed ramie fibers in an aqueous solution of 14 parts by weight of sodium hydroxide at a bath ratio of 1:150. After soaking in a water bath at 40°C for 2 hours, place the reactor in an ultrasonic cleaner. The alkaline-treated r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com