3D printing xanthan gum hydrogel stent and preparation method thereof

A 3D printing and xanthan gum technology, applied in the field of medical supplies, can solve the problems of easy damage, poor water resistance, poor environmental performance, etc., and achieve the effects of fast curing time, improved light absorption capacity, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A modified photoinitiator is prepared, and the modified photoinitiator is made by the following steps:

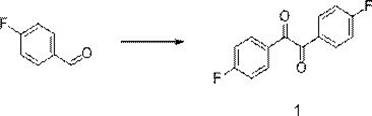

[0039] Step S1: add vitamin B1 and p-fluorobenzaldehyde to the flask, then add triethylamine, heat up to 90 ° C, and react for 24 hours, then add acetic acid, ferric chloride, copper sulfate, and sodium nitrate, reflux for 5 hours, and cool to After room temperature, deionized water was added, and after extraction with dichloromethane, the organic layer was removed from dichloromethane, and recrystallized with acetic acid to obtain intermediate 1; wherein vitamin B1, p-fluorobenzaldehyde, triethylamine, acetic acid, trichloride The dosage ratio of iron, copper sulfate and sodium nitrate is 1mmol: 40mmol: 1.4g: 25mL: 0.5g: 0.1g: 1.7g;

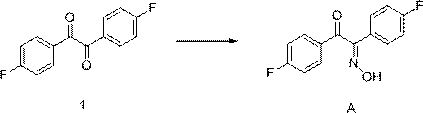

[0040] Step S2: add intermediate 1, hydroxylamine hydrochloride and sodium hydroxide into the flask, then add tetrahydrofuran and deionized water, heat under reflux for 10 hours, and after the reaction ends, obtain functional monomer A...

Embodiment 2

[0046] A modified photoinitiator is prepared, and the modified photoinitiator is made by the following steps:

[0047] Step S1: add vitamin B1 and p-fluorobenzaldehyde to the flask, then add triethylamine, heat up to 90 ° C, and react for 24 hours, then add acetic acid, ferric chloride, copper sulfate, and sodium nitrate, reflux for 5 hours, and cool to After room temperature, deionized water was added, and after extraction with dichloromethane, the organic layer was removed from dichloromethane, and recrystallized with acetic acid to obtain intermediate 1; wherein vitamin B1, p-fluorobenzaldehyde, triethylamine, acetic acid, trichloride The dosage ratio of iron, copper sulfate and sodium nitrate is 1mmol: 40mmol: 1.4g: 25mL: 0.5g: 0.1g: 1.7g;

[0048] Step S2: Add intermediate 1, hydroxylamine hydrochloride and sodium hydroxide into the flask, then add tetrahydrofuran and deionized water, heat under reflux for 11 h, and after the reaction ends, obtain functional monomer A; wh...

Embodiment 3

[0054] A modified photoinitiator is prepared, and the modified photoinitiator is made by the following steps:

[0055] Step S1: add vitamin B1 and p-fluorobenzaldehyde to the flask, then add triethylamine, heat up to 90 ° C, and react for 24 hours, then add acetic acid, ferric chloride, copper sulfate, and sodium nitrate, reflux for 5 hours, and cool to After room temperature, deionized water was added, and after extraction with dichloromethane, the organic layer was removed from dichloromethane, and recrystallized with acetic acid to obtain intermediate 1; wherein vitamin B1, p-fluorobenzaldehyde, triethylamine, acetic acid, trichloride The dosage ratio of iron, copper sulfate and sodium nitrate is 1mmol: 40mmol: 1.4g: 25mL: 0.5g: 0.1g: 1.7g;

[0056] Step S2: Add intermediate 1, hydroxylamine hydrochloride and sodium hydroxide into the flask, then add tetrahydrofuran and deionized water, heat under reflux for 12 hours, and after the reaction ends, obtain functional monomer A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com