Oxygen-carrying phospholipid micro-capsule, preparation method thereof and application of oxygen-carrying phospholipid micro-capsule in preparation of anti-hypoxic drugs

A technology of oxygen-loaded phospholipids and myristoyl phosphatidylcholine, which is applied in the field of medicine, can solve the problems of restricting the marketization process of products, the inability to realize small laboratory tests, and low bioavailability, and achieve a simple, controllable and stable preparation method Good stability and biocompatibility, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

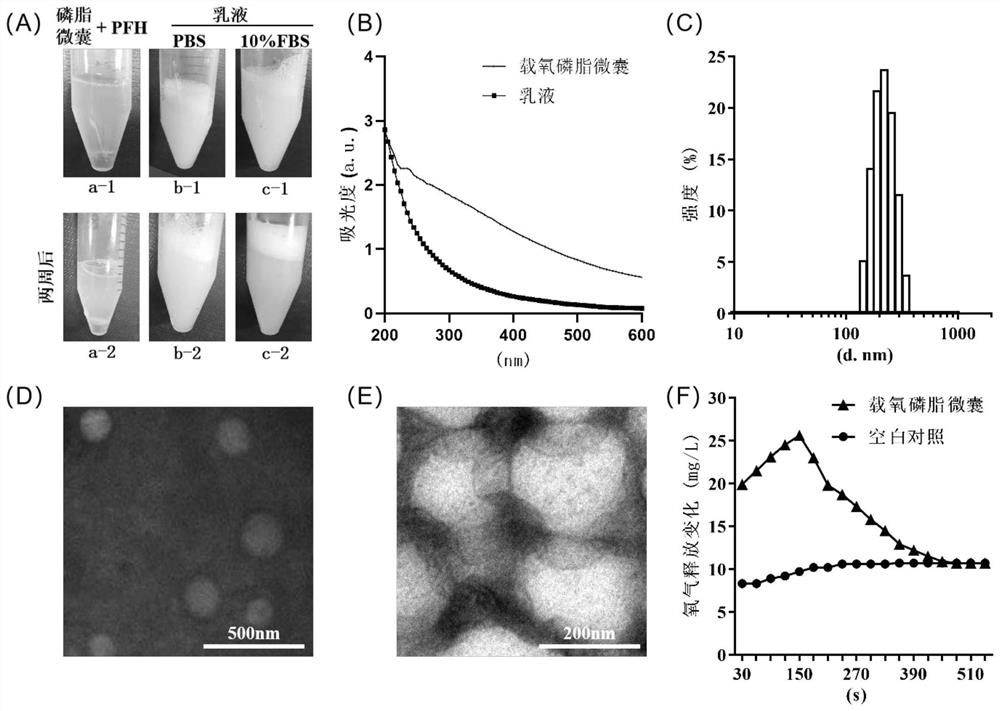

[0039] A preparation method of oxygen-loaded phospholipid microcapsules, comprising the steps of:

[0040] Add 20 mg of myristoylphosphatidylcholine, 75 mg of dipalmitoylphosphatidylcholine, 5 mg of dipalmitoylphosphatidylethanol-polyethylene glycol 2000-triphenylphosphate, and 10 mL of dimethyl sulfoxide to a vessel using phacoemulsification Machine, ultrasonic power is 300W, ultrasonic time is 10min, dissolves, and obtains clear solution; Evaporate under reduced pressure to remove dimethyl sulfoxide, a layer of uniform translucent pale yellow film is attached on the inner wall of the container; Vacuum dry, add 5mL ultrapure water and Hydrate in an ice bath. The set temperature for hydration in the ice bath is 0°C, and the hydration time is 10 minutes to obtain phospholipid microcapsules, which are placed in an ice bath; 3 mL of perfluorohexane is added to obtain a mixed system. 100W, 5min / time, 10 times, each interval of 5min, ultrasonically dispersed until the mixed system ...

Embodiment 2

[0043] A preparation method of oxygen-loaded phospholipid microcapsules, comprising the steps of:

[0044] Add 20mg myristoylphosphatidylcholine, 65mg dipalmitoylphosphatidylcholine, 8mg dipalmitoylphosphatidylethanol-polyethylene glycol 2000-triphenyl phosphate and a mixture of 10mL chloroform and methanol ( Organic solvent: the volume ratio of chloroform to methanol is 4:1), using a ultrasonic emulsification machine, the ultrasonic power is 200W, and the ultrasonic time is 15min, dissolve to obtain a clear solution; remove the organic solvent by evaporation under reduced pressure, and adhere to the inner wall of the container A uniform and transparent light yellow film; vacuum drying, adding 5mL ultrapure water and hydrating in an ice bath, the set temperature for hydration in the ice bath is 0°C, and the hydration time is 15min to obtain phospholipid microcapsules, which are placed in In an ice bath; add 8mL perfluorohexane to obtain a mixed system. At a power of 80W, 5min / ...

Embodiment 3

[0046]A preparation method of oxygen-loaded phospholipid microcapsules, comprising the steps of:

[0047] Add 20 mg of myristoylphosphatidylcholine, 85 mg of dipalmitoylphosphatidylcholine, 2 mg of dipalmitoylphosphatidylethanol-polyethylene glycol 2000-triphenyl phosphate and a mixture of 10 mL of chloroform and methanol ( Organic solvent, the volume ratio of chloroform and methanol is 4:1), use ultrasonic emulsification machine, ultrasonic power is 350W, ultrasonic time is 5min, dissolve, obtain clear solution; A uniform and transparent light yellow film; vacuum drying, adding 5mL ultrapure water and hydrating in an ice bath, the set temperature for hydration in the ice bath is 0 °C, and the hydration time is 5min to obtain phospholipid microcapsules, which are placed in In an ice bath; add 12mL of perfluorohexane to obtain a mixed system, and at a power of 120W, 5min / time, 5 times, with an interval of 5min, ultrasonically disperse until the mixed system has no stratificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com