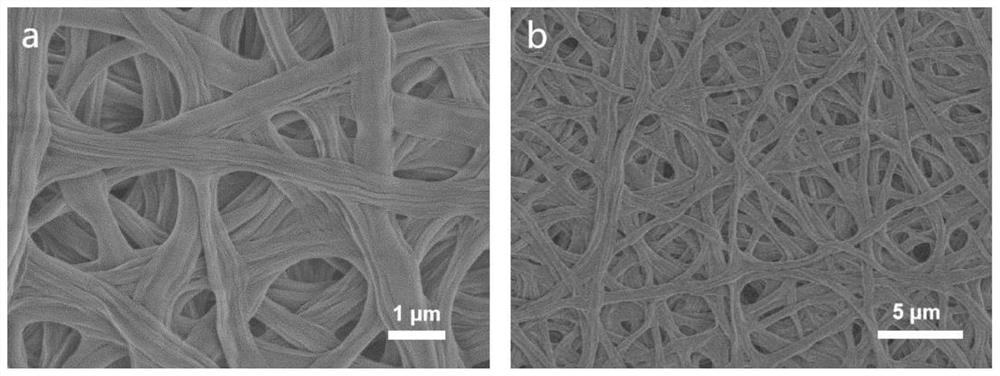

Electrostatic spinning polyimide uniform small-aperture nanofiber membrane as well as preparation method and application thereof

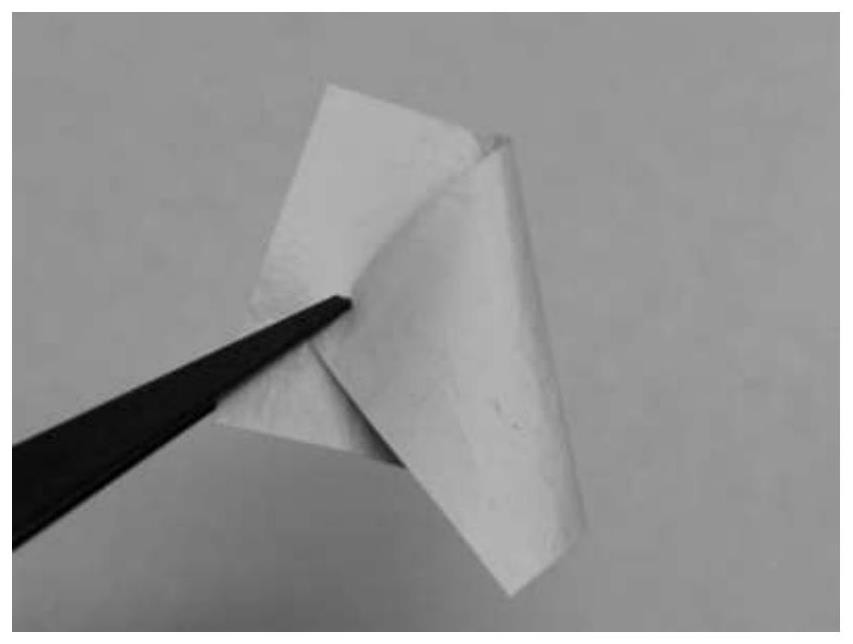

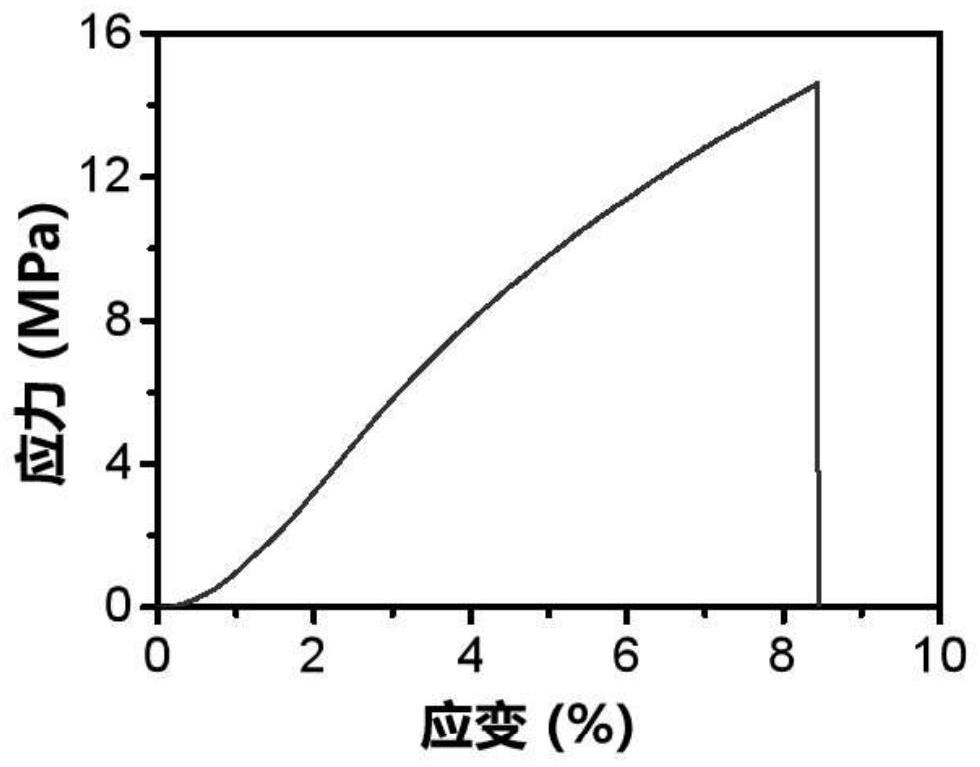

A nanofiber membrane, polyimide technology, applied in fiber processing, chemical instruments and methods, membrane technology, etc., can solve the problems of no interaction, poor mechanical properties of nanofiber membrane, etc., achieve uniform distribution and simple preparation method The effect of easy, good shape recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of Electrospun Polyimide Uniform Small Pore Nanofiber Membrane

[0035] (1) Use a balance to weigh 8.00g of 4,4'-diaminodiphenyl ether into a three-necked flask, and then add 94.76g of N,N-dimethylacetamide. At the same time, the stirring motor was turned on for stirring and nitrogen gas was kept flowing in, so that the reaction system was in a nitrogen atmosphere. After completely dissolving, add 8.72 g of pyromellitic dianhydride in four batches. Stirring is continued at low temperature until a light yellow, uniform and viscous polyamic acid spinning solution precursor is obtained.

[0036] (2) Weigh 8.36g of polystyrene into a blue bottle, add 47.37g of N,N-dimethylacetamide, control the solid content to 15%, and use magnetic stirring to completely dissolve the polystyrene.

[0037] (3) Weigh 10.00 g and 5.00 g of the solutions obtained in step (1) and step (2), respectively, add them into a sample bottle, stir them evenly with a magnet to ob...

Embodiment 2

[0040] Example 2: Preparation of Electrospun Polyimide Uniform Small Pore Nanofiber Membrane

[0041] (1) Use a balance to weigh 8.00g of 4,4'-diaminodiphenyl ether into a three-necked flask, and then add 94.76g of N,N-dimethylacetamide. At the same time, the stirring motor was turned on for stirring and nitrogen gas was kept flowing in, so that the reaction system was in a nitrogen atmosphere. After completely dissolving, add 8.72 g of pyromellitic dianhydride in four batches. Stirring is continued at low temperature until a pale yellow uniform viscous polyamic acid spinning precursor is obtained.

[0042] (2) Weigh 8.36g of polystyrene into a blue bottle, add 47.37g of N,N-dimethylacetamide, control the solid content to 15%, and use magnetic stirring to completely dissolve the polystyrene.

[0043] (3) Weigh 10.00 g and 2.00 g of the solutions obtained in step (1) and step (2), respectively, add them into a sample bottle, stir them evenly with a magnet to obtain a mixed so...

Embodiment 3

[0046] Example 3: Preparation of Electrospun Polyimide Uniform Small Pore Nanofiber Membrane

[0047](1) Use a balance to weigh 8.00g of 4,4'-diaminodiphenyl ether into a three-necked flask, and then add 94.76g of N,N-dimethylacetamide. At the same time, the stirring motor was turned on for stirring and nitrogen gas was kept flowing in, so that the reaction system was in a nitrogen atmosphere. After completely dissolving, add 8.72 g of pyromellitic dianhydride in four batches. Stirring is continued at low temperature until a light yellow, uniform and viscous polyamic acid spinning solution precursor is obtained.

[0048] (2) Weigh 8.36g of polystyrene into a blue bottle, add 47.37g of N,N-dimethylacetamide, control the solid content to 15%, and use magnetic stirring to completely dissolve the polystyrene.

[0049] (3) Weigh 10.00 g and 10.00 g of the solutions obtained in step (1) and step (2), respectively, add them into a sample bottle, stir them evenly with a magnet to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com