High-temperature-resistant polyimide composite material as well as preparation method and application thereof

A technology of polyimide and composite materials, which is applied in the field of polyimide composite materials and its preparation, and can solve the problems of cumbersome reaction process and high synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a kind of preparation method of high temperature resistant polyimide composite material, comprises the following steps:

[0046] The imide oligomer monomer and polyimide prepolymer are sequentially subjected to thermal imidization reaction and curing crosslinking reaction to obtain a high temperature resistant polyimide composite material.

[0047] In the present invention, the reaction temperature of the thermal imidization reaction is 240-260°C, preferably 245-255°C, more preferably 250°C. The reaction time is 1.5-2.5 h, preferably 1.8-2.2 h, more preferably 2 h.

[0048] The reaction temperature of the curing crosslinking reaction is 370-390°C, preferably 375-385°C, more preferably 380°C. The reaction time is 1.5-2.5 h, preferably 1.8-2.2 h, more preferably 2 h.

[0049] The concrete operation steps of described preparation polyimide composite material are:

[0050] Stir and dissolve the imide oligomer monomer with dichloromethane, add it to...

Embodiment 1

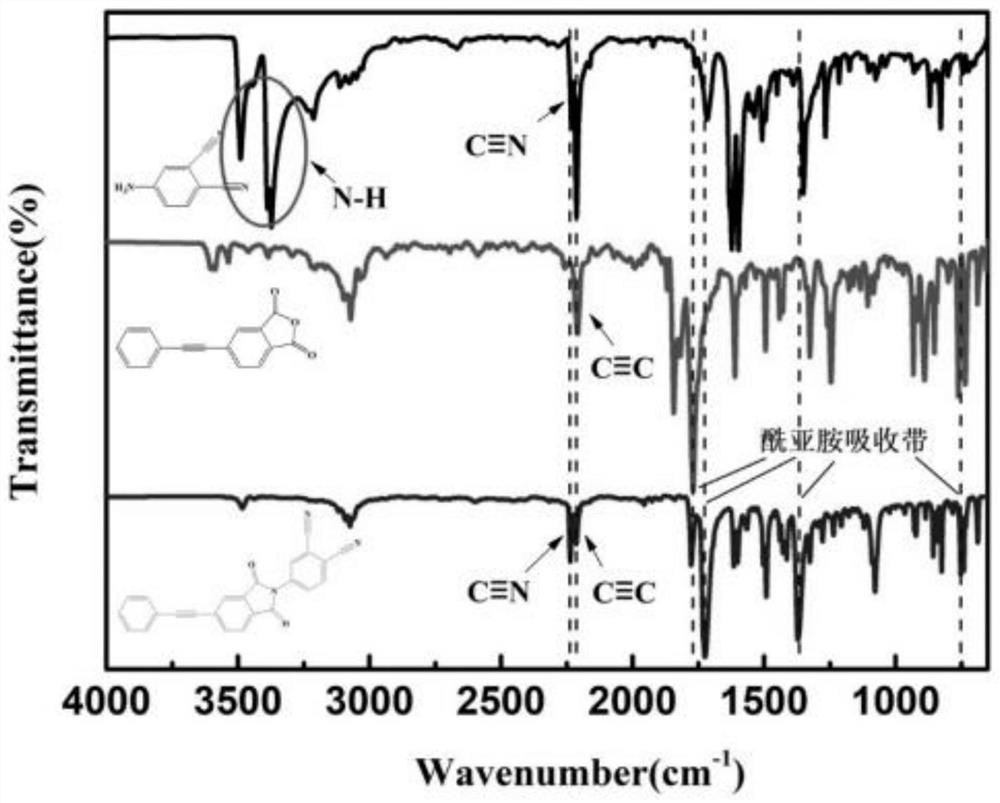

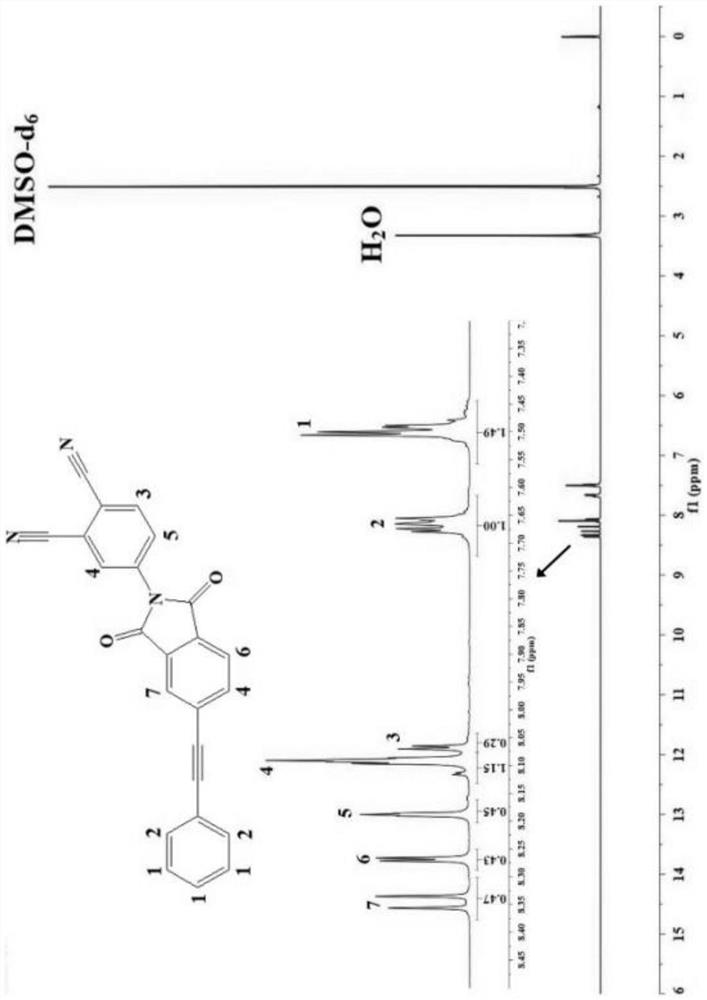

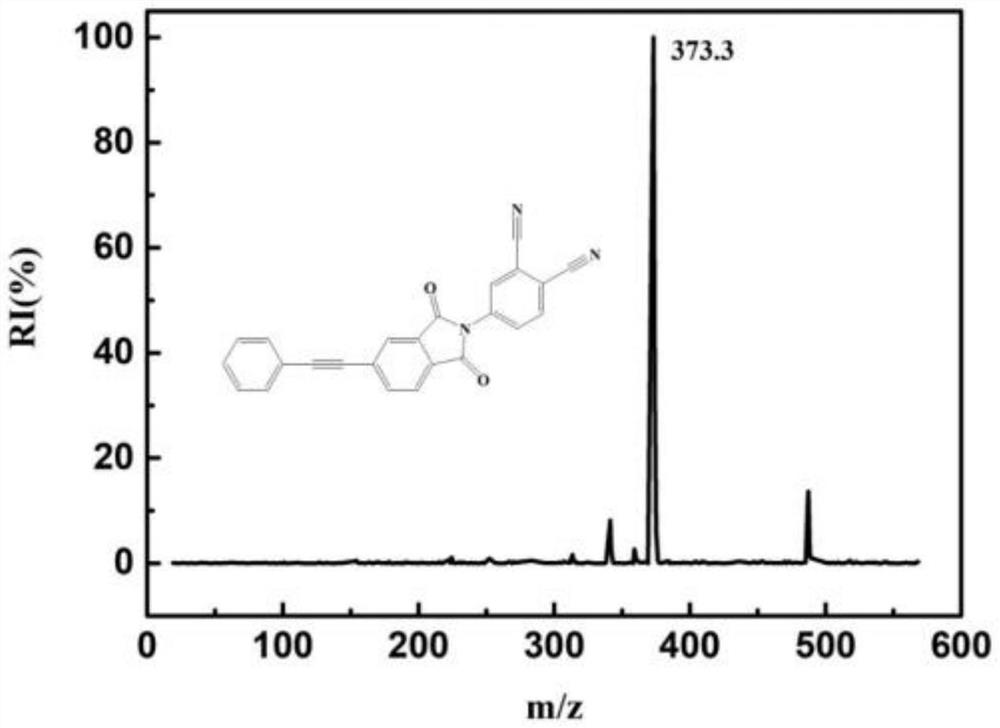

[0085] Present embodiment is the preparation of imide oligomer monomer, and the raw material used in present embodiment is 4-nitrophthalonitrile (APN), and concrete operation steps are as follows:

[0086] Weigh 45.13g (200mmol) SnCl in a three-necked flask equipped with mechanical stirring 2` 2H 2 O in a 250mL three-necked flask equipped with mechanical stirring, add 50mL of absolute ethanol and stir to dissolve. After the solution is stirred uniformly, add 8.66g (50mmol) of 4-nitrophthalonitrile, and add slowly in batches to prevent Pour the material, stir at room temperature for 10 minutes, then raise the temperature to 80°C to condense and reflux, react for 3 to 4 hours, and use the TCL method to monitor the reaction degree at all times. After the reaction, cool to room temperature, evaporate most of the ethanol solvent, pour into a 500mL beaker, add 150mL deionized water and 150mL ethyl acetate, add solid NaOH, NaHCO 3 The pH of the solution was adjusted to 9, and the s...

Embodiment 2

[0089] This embodiment is the preparation of imide oligomer monomer, and the raw material used in this embodiment is 4-nitrophthalonitrile, and the specific operation steps are as follows:

[0090] Weigh 45.13g (200mmol) SnCl in a three-necked flask equipped with mechanical stirring 2` 2H 2 O in a 250mL three-necked flask equipped with mechanical stirring, add 50mL of absolute ethanol and stir to dissolve. After the solution is stirred uniformly, add 8.66g (50mmol) of 4-nitrophthalonitrile, and add slowly in batches to prevent Pour the material, stir at room temperature for 10 minutes, then raise the temperature to 80°C to condense and reflux, react for 3 to 4 hours, and use the TCL method to monitor the reaction degree at all times. After the reaction, cool to room temperature, evaporate most of the ethanol solvent, pour into a 500mL beaker, add 150mL deionized water and 150mL ethyl acetate, add solid NaOH, NaHCO 3 The pH of the solution was adjusted to 9, and the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com