Extraction method of oil-tea cake protein and application of oil-tea cake protein

An extraction method and a technology for protein extraction liquid, which are applied in the preparation methods of peptides, protein adhesives, chemical instruments and methods, etc., can solve the problems of difficulty in controlling the extraction process and change the structural properties of proteins, and achieve low destructive, enhanced Dissolution rate, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

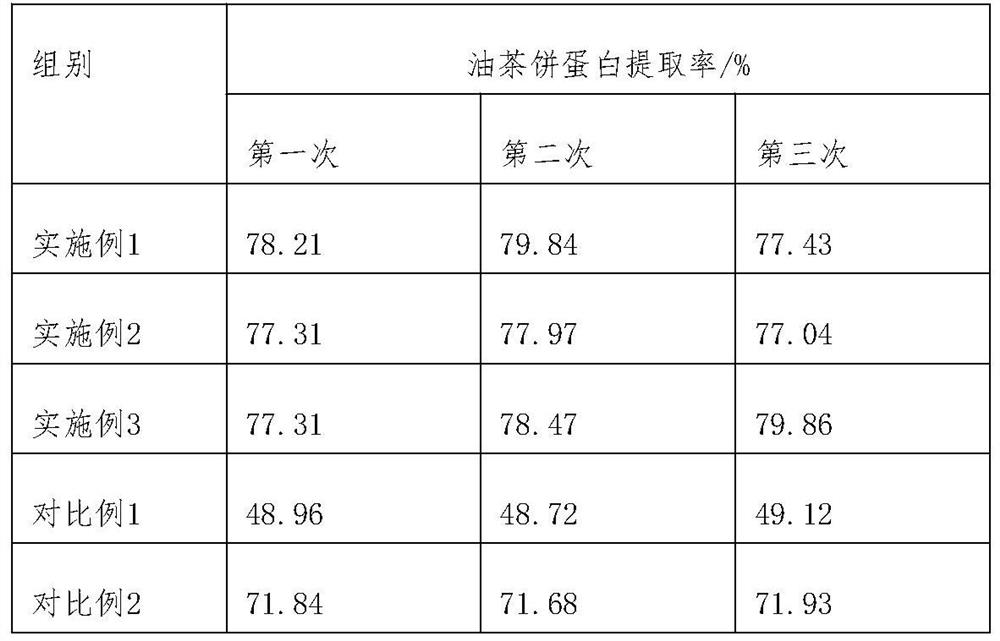

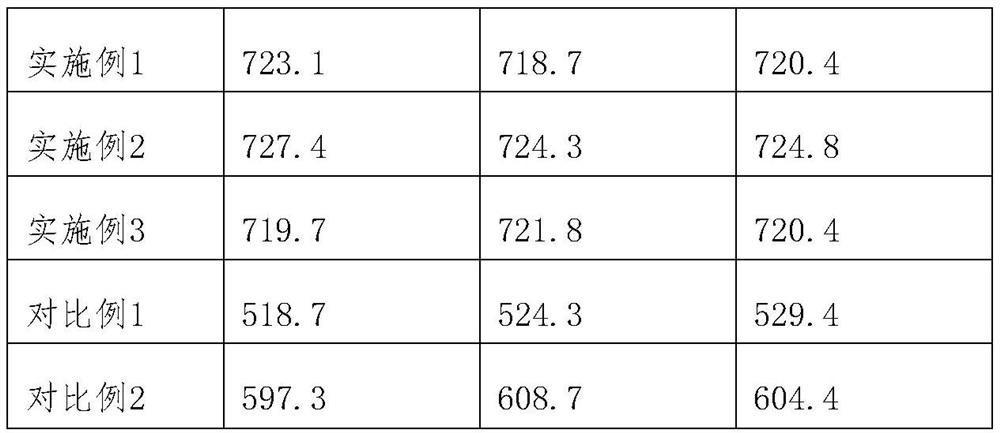

Examples

Embodiment 1

[0028] A method for extracting camellia cake protein, comprising the following steps:

[0029] (1) Pretreatment: add 6 times the amount of acetone to the camellia oleifera cake, stir quickly at 0°C to 2°C, filter, and rinse with trimethylsilyl ether to obtain a pretreatment material;

[0030] (2) Secondary pretreatment: add immobilized enzyme accounting for 10% of its mass and protein stabilizer accounting for 10% of its mass to the primary pretreatment material, and treat it at 30°C to 35°C for 5 hours to obtain secondary pretreatment. processing material;

[0031] (3) Differential pressure extraction: add the secondary pretreatment material to 8 times of sodium pyrophosphate buffer with a pH of 6, extract once at room temperature with a pressure difference of -0.1 MPa to 60 MPa, and filter to obtain Camellia oleifera Cake protein extract;

[0032] (4) Concentration and drying treatment: adjust the pH value of the Camellia oleifera cake protein extract to be 4.2, stand for ...

Embodiment 2

[0038] A method for extracting camellia cake protein, comprising the following steps:

[0039] (1) Pretreatment: add 8 times the amount of acetone to the Camellia oleifera cake, stir quickly at 0°C to 2°C, filter, and rinse with trimethylsilyl ether to obtain a pretreatment material;

[0040] (2) Secondary pretreatment: add immobilized enzyme accounting for 15% of its mass and protein stabilizer accounting for 10% of its mass to the primary pretreatment material, and treat it at 30°C to 35°C for 6 hours to obtain secondary pretreatment. material;

[0041] (3) Differential pressure extraction: add the secondary pretreatment material to 9 times of sodium pyrophosphate buffer with a pH of 6, extract once at room temperature with a pressure difference of -0.1 MPa to 60 MPa, and filter to obtain Camellia oleifera Cake protein extract;

[0042] (4) Concentration and drying treatment: adjust the pH value of the Camellia oleifera cake protein extract to be 4.2, stand for precipitati...

Embodiment 3

[0048] A method for extracting camellia cake protein, comprising the following steps:

[0049] (1) Pretreatment: Add 8 times the amount of acetone to the camellia oil cake, stir quickly at 2°C to 4°C, filter, and rinse with trimethylsilyl ether to obtain a pretreatment material;

[0050] (2) Secondary pretreatment: add immobilized enzyme accounting for 15% of its mass and protein stabilizer accounting for 15% of its mass to the primary pretreatment material, and treat it at 30°C to 35°C for 6 hours to obtain secondary pretreatment. material;

[0051] (3) Differential pressure extraction: add the secondary pretreatment material to 10 times of sodium pyrophosphate buffer with a pH of 6, extract once at room temperature with a pressure difference of -0.1 MPa to 60 MPa, and filter to obtain Camellia oleifera Cake protein extract;

[0052] (4) Concentration and drying treatment: adjust the pH value of the Camellia oleifera cake protein extract to be 4.2, stand for precipitation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com