Organic silicone-modified alkyd resin and preparation method thereof

A technology of alkyd resin and organosilicon, which is applied in the field of organosilicon-modified alkyd resin and its preparation, which can solve the problems of complex refining process, poor quality, testicular atrophy, etc., and achieve high cross-linking reactivity and excellent film-forming performance , Excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

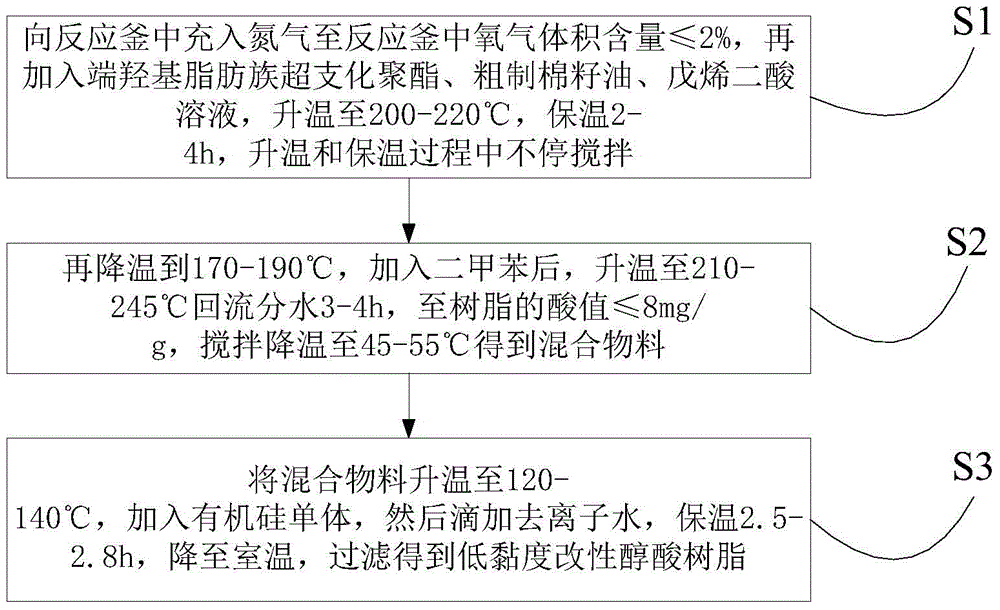

[0022] refer to figure 1 , the preparation method of above-mentioned organosilicon modified alkyd resin that the present invention proposes, comprises the steps:

[0023] S1. Fill the reactor with nitrogen until the oxygen volume content in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, crude cottonseed oil, and glutaconic acid solution, heat up to 200-220°C, and keep warm 2-4h, keep stirring during the heating and heat preservation process;

[0024] S2, then lower the temperature to 170-190°C, add xylene, heat up to 210-245°C, reflux and divide water for 3-4 hours, until the acid value of the resin is ≤8mg / g, stir and cool down to 45-55°C to obtain a mixed material;

[0025] S3. Raise the temperature of the mixture to 120-140° C., add silicone monomer, then drop deionized water, keep warm for 2.5-2.8 hours, cool down to room temperature, and filter to obtain silicone-modified alkyd resin.

Embodiment 1

[0028] A kind of organosilicon modified alkyd resin proposed by the present invention, its raw material comprises by weight: 30 parts of hydroxyl-terminated aliphatic hyperbranched polyester, 30 parts of crude cottonseed oil, 50 parts of glutaconedic acid solution, 8 parts of xylene Parts, 25 parts of vinyltriethoxysilane, 15 parts of deionized water.

[0029] The preparation method of the above-mentioned organosilicon modified alkyd resin that the present invention also proposes comprises the steps:

[0030] S1. Fill the reactor with nitrogen until the volume content of oxygen in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, crude cottonseed oil, and glutaconedic acid solution, and heat up to 210°C at a heating rate of 10°C / min, keep warm for 3.2h, keep stirring during heating up and keeping warm;

[0031] S2, then lower the temperature to 175°C, add xylene, heat up to 235°C, reflux and divide water for 3.4 hours, until the acid value of...

Embodiment 2

[0034] A kind of organosilicon modified alkyd resin proposed by the present invention, its raw material comprises by weight: 37 parts of hydroxyl-terminated aliphatic hyperbranched polyesters, 22 parts of crude cottonseed oil, 56 parts of glutaconedic acid solution, 5 parts of xylene Parts, 28 parts of methyltriethoxysilane, 12 parts of deionized water.

[0035] The preparation method of the above-mentioned organosilicon modified alkyd resin that the present invention also proposes comprises the steps:

[0036] S1. Fill the reactor with nitrogen until the volume content of oxygen in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, crude cottonseed oil, and glutaconedic acid solution, and heat up to 200°C at a heating rate of 8°C / min, keep warm for 4h, keep stirring during heating and keeping warm;

[0037] S2, then lower the temperature to 170°C, add xylene, raise the temperature to 245°C, reflux and divide water for 3 hours, until the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com