High-toughness poly (p-dioxanone) absorbable silk yarn and preparation method thereof

A technology of polydioxanone and high toughness, which is applied in the field of biomedical polymer materials, and can solve the problem that the strength and modulus of PPDO threads cannot meet the requirements for the use of sutures, and the inability to obtain high-crystallinity PPDO threads and the crystallization rate of PPDO Slow and other problems, to avoid poor processing stability, easy to be identified, and convenient for surgical operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

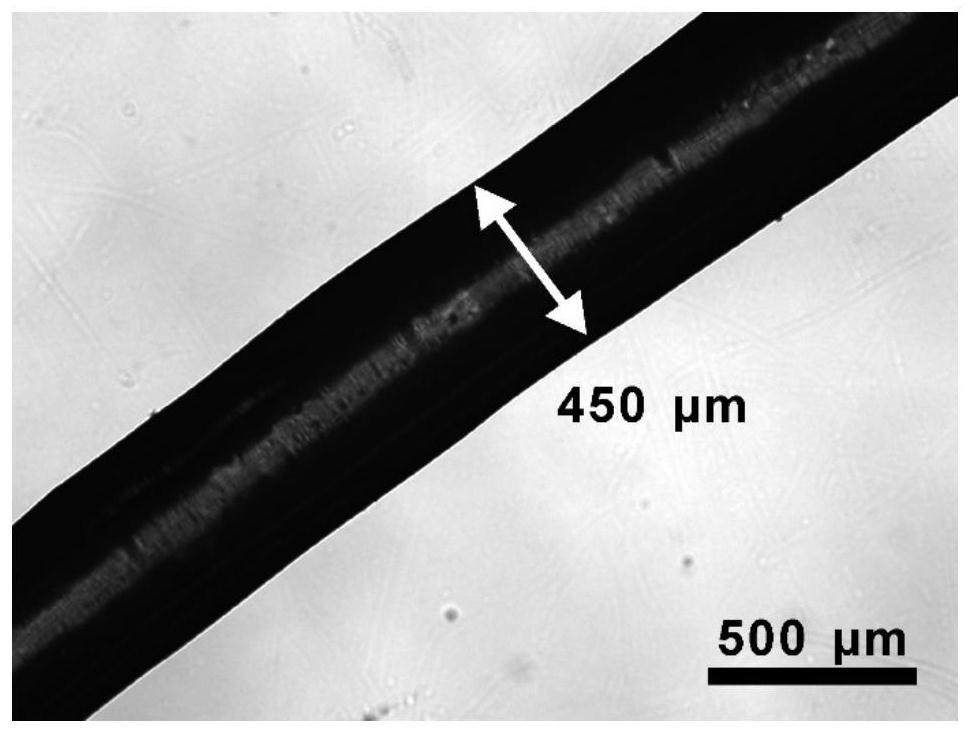

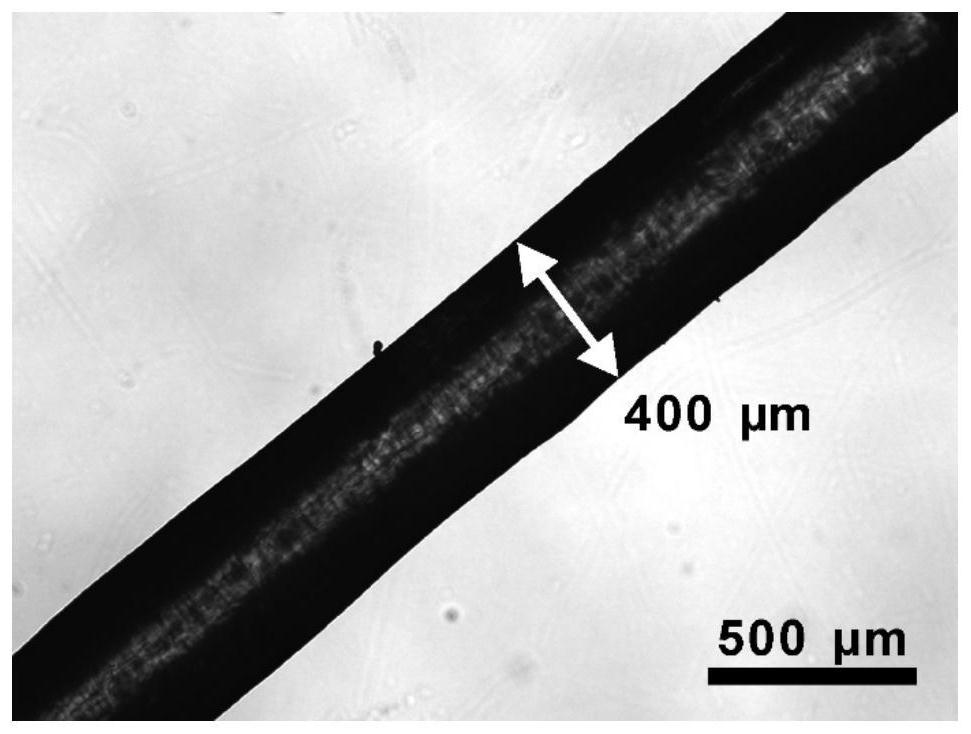

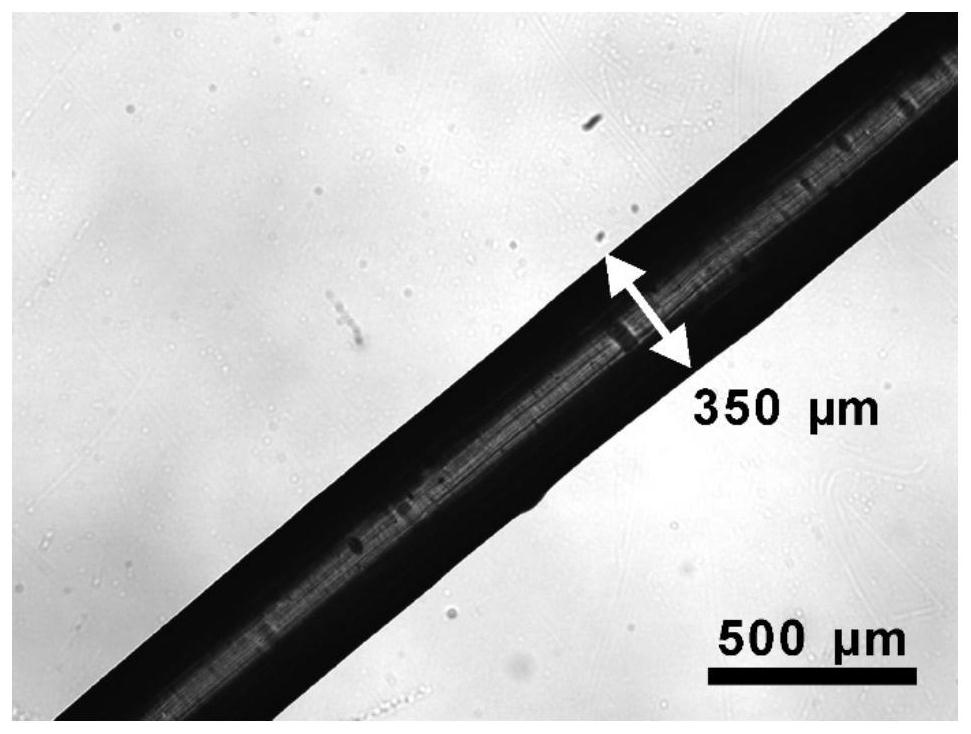

Image

Examples

preparation example Construction

[0033] A kind of preparation method of high tenacity polydioxanone absorbable thread of the present invention, concrete steps are as follows:

[0034] S1 In terms of mass fraction, 0.1% to 2.0% of pigment and 98% to 99.9% of PPDO raw material with high molecular weight and narrow distribution are mechanically mixed at 20 to 30°C for 30 to 90 minutes, and the stirring rate is 300 to 600r / min to obtain PPDO / Pigment raw material mixing system;

[0035] S2 Add the PPDO / pigment raw material mixing system into the twin-screw extruder at a feeding speed of 5-7r / min. The PPDO / pigment mixing system is melted and extruded through the conveying compression section, the melting section and the metering section of the twin-screw extruder. The extrudate is forced to cool to room temperature through circulating cooling water to obtain a PPDO / pigment blend;

[0036] S3 pelletize the PPDO / pigment blend, place the pellets in a vacuum drying oven, and dry at 60°C until the water content is les...

Embodiment 1

[0042] (1) Mechanical mixing of D&C Violet 2 and PPDO: mechanically mix D&C Violet powder with a mass percentage of 0.5% and PPDO with a mass percentage of 99.5%, and keep stirring at 30°C for 60 min;

[0043] (2) Preparation of D&C Violet 2 / PPDO blend: put the mixed D&C Violet 2 / PPDO in a twin-screw extruder for melt blending and extrusion, and the extruder conveys the temperature of the compression section, the melting section and the metering section Set at 100°C, 120°C and 110°C, set the speed of the main engine at 100r / min, and the feeding speed at 5r / min, then extrude the blend into strands for forced cooling and pelletizing, and dry at 60°C to a water content not higher than 0.01% of its own weight;

[0044] (3) Preparation of PPDO absorbable yarn by melt spinning: Melt spinning the above dried D&C Purple 2 / PPDO extruded pellets, setting the extrusion temperature at 105°C, preheating time for 10 minutes, and drawing The stretch ratio is 10 / 1, the extrusion rate is 0.5mm / ...

Embodiment 2

[0046] (1) Mechanical mixing of D&C Violet 2 and PPDO: mechanically mix D&C Violet powder with a mass percentage of 0.1% and PPDO with a mass percentage of 99.9%, and keep stirring at 30°C for 90 min;

[0047] (2) Preparation of D&C Violet 2 / PPDO blend: put the mixed D&C Violet 2 / PPDO in a twin-screw extruder for melt blending and extrusion, and the extruder conveys the temperature of the compression section, the melting section and the metering section Set at 100°C, 130°C and 120°C, set the speed of the main engine at 110r / min, and the feeding speed at 6r / min, then extrude the blend into filaments, force cooling and pelletizing, and dry at 60°C to a water content not higher than 0.01% of its own weight;

[0048] (3) Preparation of PPDO absorbable yarn by melt spinning: Melt spinning the above dried D&C purple 2 / PPDO extruded pellets, setting the extrusion temperature at 115°C, preheating time for 8 minutes, and drawing The stretch ratio is 20 / 1, the extrusion rate is 1mm / s, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com