All-organic composite material film and preparation method and application thereof

A composite material film and organic filler technology, applied in the field of all-organic composite material film and its preparation, can solve the problem of reduced breakdown field strength, inability to meet high dielectric constant, high breakdown strength, high energy density processing performance, composite Increased material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

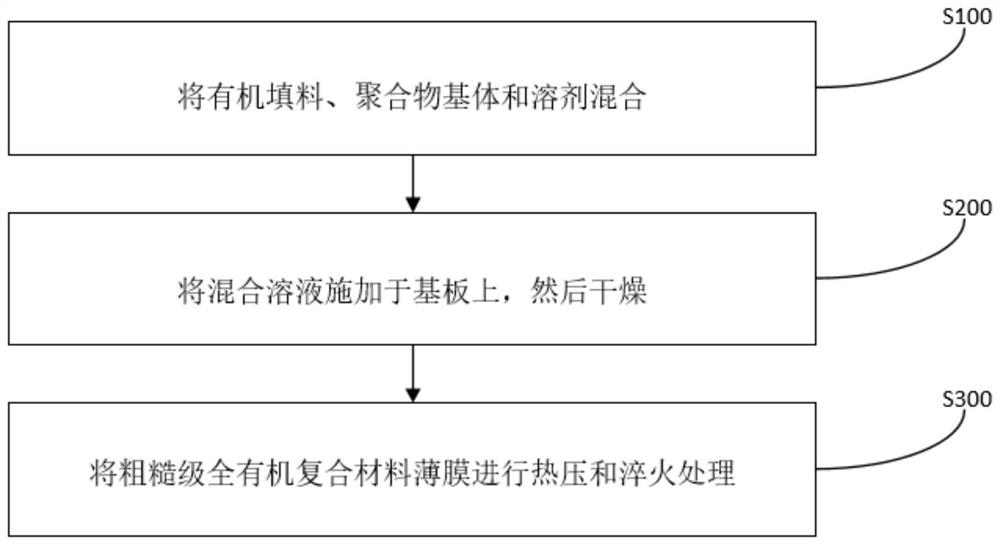

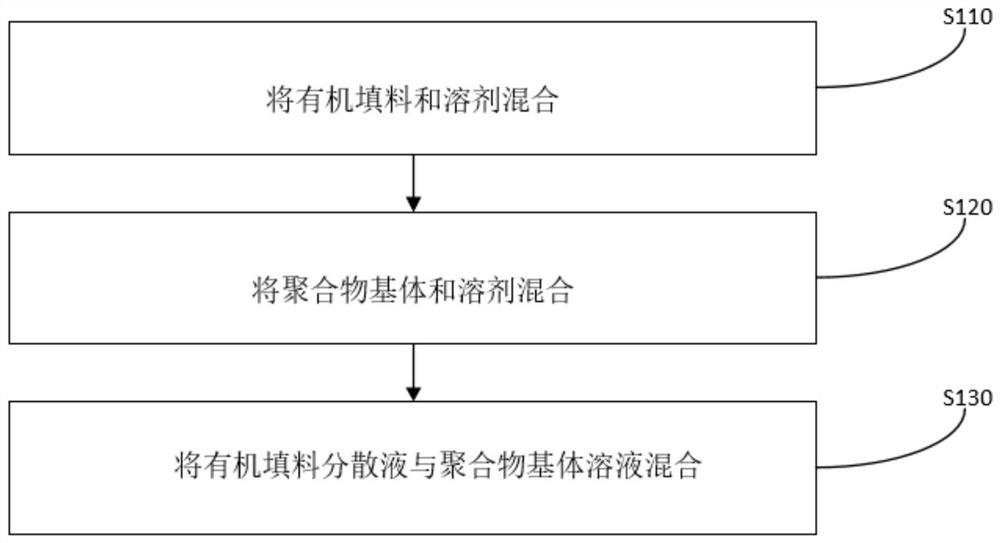

[0061] According to the method for preparing an all-organic composite film according to an embodiment of the present invention, by mixing an organic filler, a polymer matrix, and a solvent, an organic filler including nitrile rubber is dispersed in a polyvinylidene fluoride-co-hexafluoropropylene polymer In the material matrix, the polymer including polyvinylidene fluoride-co-hexafluoropropylene is used as the matrix, and the organic filler including nitrile rubber is used as the dispersed phase. As an organic material, nitrile rubber is mixed with polyvinylidene fluoride During the blending process of ethylene-co-hexafluoropropylene, the molecular chains can be cross-linked to form a cross-linked structure, and traps are introduced inside the composite material, which can play the role of trapping charges, and then the resulting mixed solution Applied on the substrate to prepare a rough-grade all-organic composite film, and then subject the rough-grade all-organic composite fi...

Embodiment 1

[0065] (1) Add 0.0051 g of nitrile rubber into 10 mL of dimethylformamide solution, then magnetically stir at 50° C. for 30 minutes, and then ultrasonically vibrate for 60 minutes with a power of 400 W to obtain a nitrile rubber solution;

[0066] (2) Add 0.5 g of polyvinylidene fluoride-co-hexafluoropropylene into 10 mL of dimethylformamide solution, and stir at 50° C. for 60 minutes to obtain a polyvinylidene fluoride-co-hexafluoropropylene solution;

[0067] (3) Mix the nitrile rubber solution with the polyvinylidene fluoride-co-hexafluoropropylene solution, and stir magnetically at 50° C. for 5 hours to obtain a mixed solution;

[0068] (4) Using the solution scraping method, the mixed solution is coated on a glass plate, and then dried at 70° C. for 12 hours to obtain a rough-grade all-organic composite film;

[0069] (5) Hot-press the rough-grade all-organic composite film at 200°C and 5MPa for 5 minutes, and finally put it into an ice-water mixture for quenching treatme...

Embodiment 2

[0071] The quality of nitrile rubber is replaced by 0.0102g, and all the other processes are the same as in Example 1.

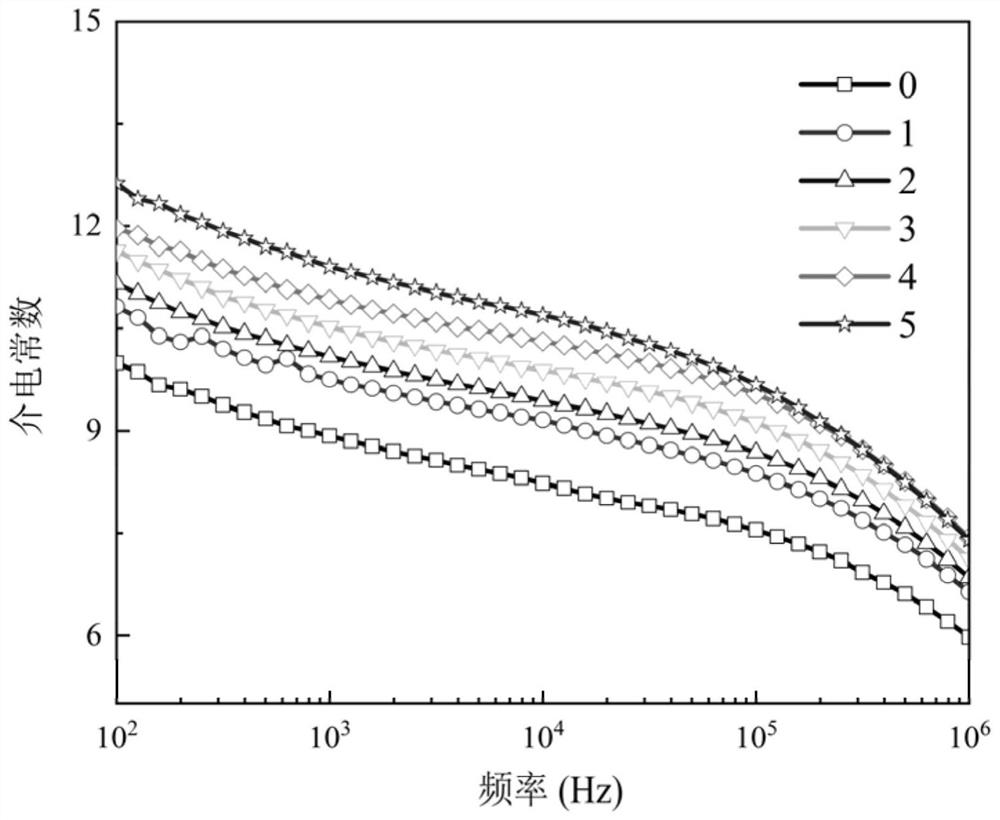

[0072] The dielectric constants, breakdown field strengths and discharge energy densities of the obtained all-organic composite films at room temperature under different frequency conditions are as follows: image 3 , 4 , Curve 2 in 5. Such as Figure 4 , 5 As shown, when the NBR content is 2wt%, the breakdown strength and discharge energy density of the composite film material are the largest, and the distribution energy reaches 510MV / m and 11.3J / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com