Composite system glass powder for secondary gate electrode silver paste of crystalline silicon solar cell

A solar cell and glass powder technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of inability to erode anti-reflection films, etc., to increase the effective contact area and improve Effect of open circuit voltage, good wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention discloses a composite system glass powder for the silver paste of the sub-gate electrode of crystalline silicon solar cells, which is applied to monocrystalline silicon SE-PERC cells.

[0029]First, glass powders of tellurite T1, borate B1 and silicate S1 were prepared respectively, and the specific steps were as follows.

[0030] (1) Batching and mixing: Weigh the raw materials of tellurite T1, borate B1 and silicate S1 according to the oxides and ratios listed in Table 1-3, and then use a mixer to fully mix them for 40 minutes .

[0031] (2) Melting glass: Put the raw materials of tellurite T1, borate B1 and silicate S1 into a corundum crucible and place them in a high-temperature resistance furnace for melting. The melting temperature of tellurite T1 is 950 o C, the time is 30 minutes; the melting temperature of borate B1 is 1050 o C. The time is 40 minutes; the melting temperature of silicate S1 is 1200 o C, the time is 50 minutes.

[0032] (3) Wa...

Embodiment 2

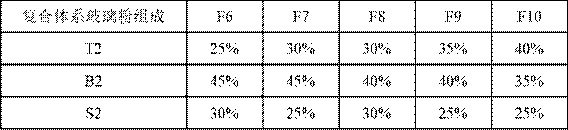

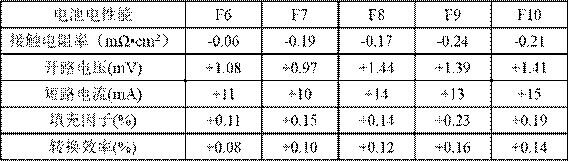

[0052] The invention discloses a composite system glass powder for the silver paste of the sub-gate electrode of crystalline silicon solar cells, which is applied to high square resistance monocrystalline silicon PERC cells.

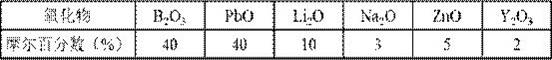

[0053] First, glass powders of tellurite T2, borate B2 and silicate S2 were prepared respectively, and the specific steps were as follows.

[0054] (1) Batching and mixing: Weigh the raw materials of tellurite T2, borate B2 and silicate S2 according to the oxides and ratios listed in Table 6-8, and then use a mixer to fully mix them for 40 minutes .

[0055] (2) Melting glass: Put the raw materials of tellurite T2, borate B2 and silicate S2 into a corundum crucible and place them in a high-temperature resistance furnace for melting. The melting temperature of tellurite T2 is 900 o C, the time is 30 minutes; the melting temperature of borate B2 is 1000 o C, the time is 40 minutes; the melting temperature of silicate S2 is 1150 o C, the time is 50 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com