Epoxy glue potting process method for tail-cover-free electric connector cable

A technology of electrical connectors and process methods, applied in the direction of connection, circuit/collector parts, circuits, etc., can solve the problems of low fatigue strength, long production cycle, weak bonding performance of potting glue, etc., and achieve fatigue strength. Large, short production cycle, high bonding performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

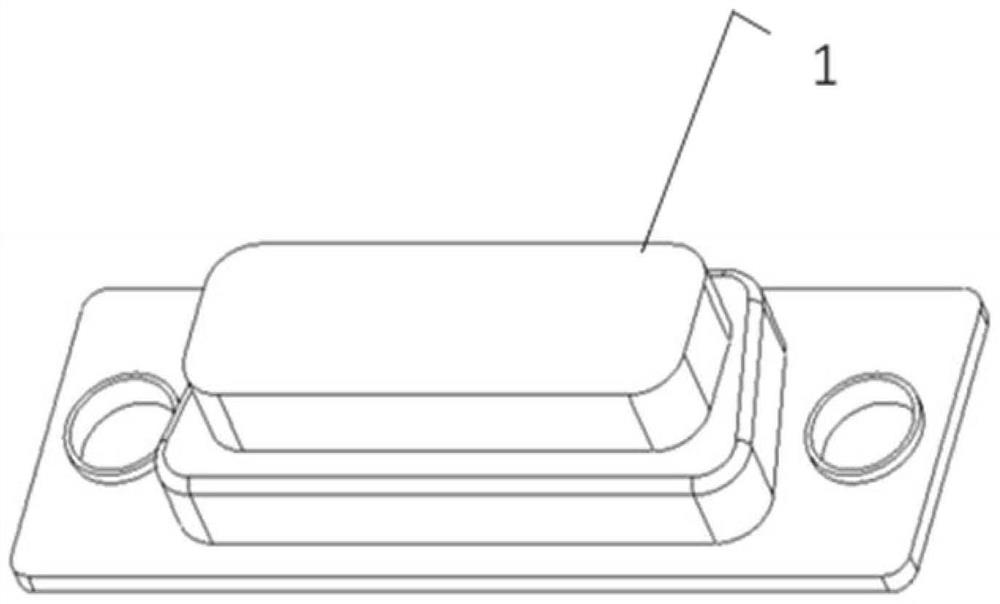

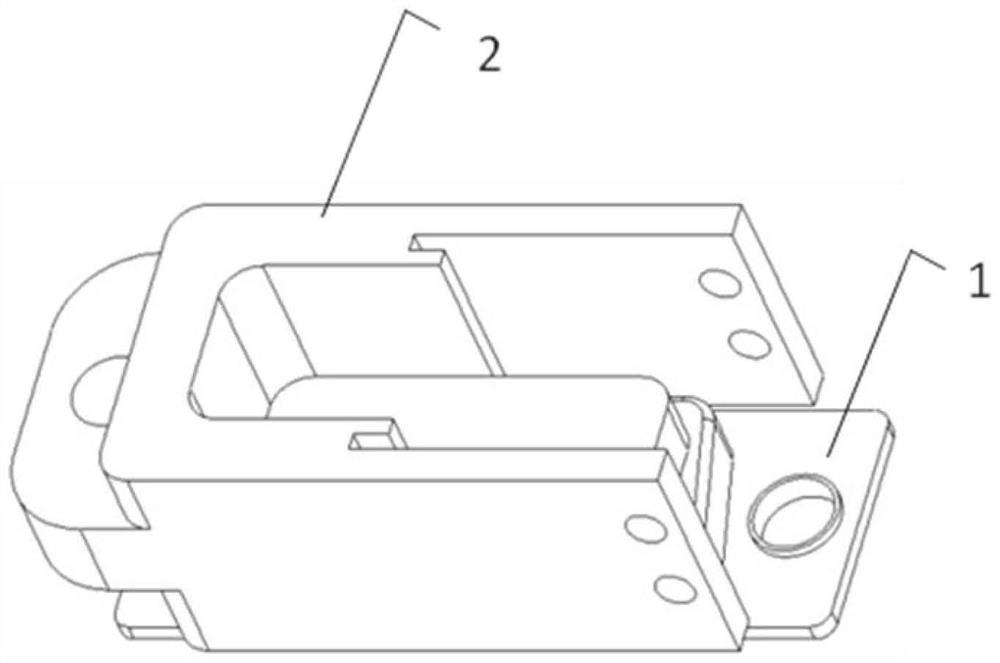

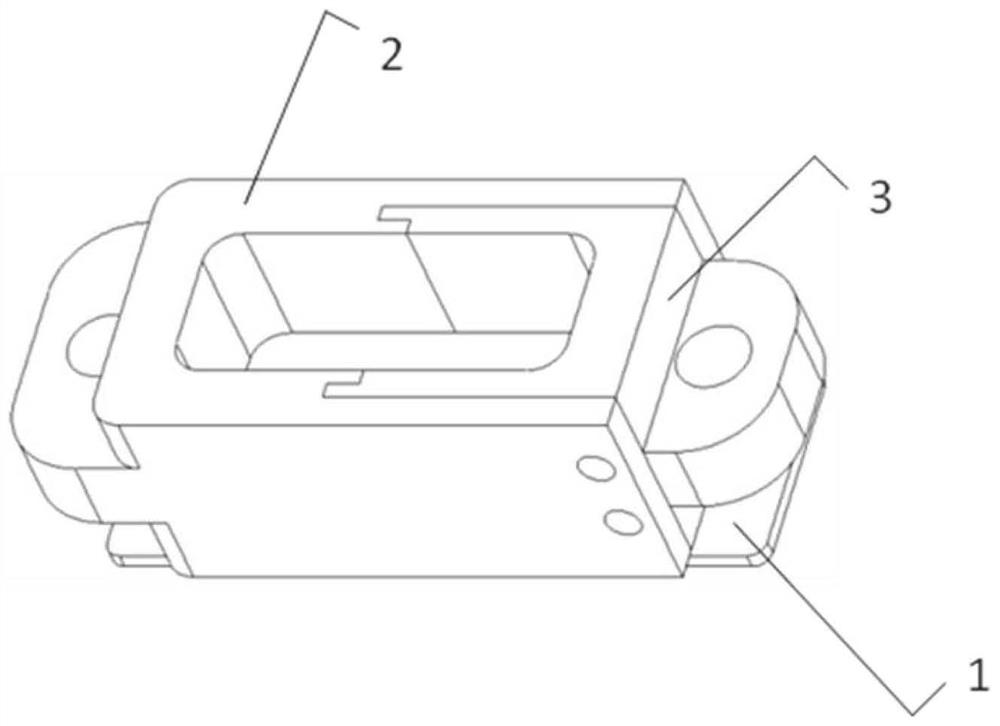

[0039] In order to facilitate environmental protection and biodegradation, polylactic acid is used as the material of the potting mold. Such as figure 1 As shown, the potting mold is designed according to the shape of the electrical connector 1 to be potted, including such as Figure 4 As shown on the left die 2 and as Figure 5 The right mold 3 shown has a matching snap-fit structure, can be combined into a potting mold, and is easy to disassemble. Use the 3D printing manufacturing method to print the left mold 2 and the right mold 3 respectively. After the left mold 2 and the right mold 3 are assembled and installed, they can be fixed on the outer surface with polyimide tape, or can be fixed with GD414 silicone rubber. Prepare the release paint, the composition of the release paint includes 7385 polyurethane varnish, 7312 polyurethane curing agent, and butyl acetate, and the mass ratio is 6:1:2; the release paint is evenly placed in the atomizing spray gun, and the atomi...

Embodiment 2

[0042] Such asfigure 1 As shown, the potting mold is designed according to the shape of the electrical connector 1 to be potted, and the potting mold includes such as Figure 4 As shown on the left die 2 and as Figure 5 The right mold 3 shown uses the 3D printing manufacturing method to print the potting mold. The material of the potting mold is polylactic acid. After the left mold and the right mold are made, polyimide tape is pasted on the outer surface to connect the two together. It can also be glued together by GD414 silicone rubber; prepare the release paint, the composition of the release paint includes 7385 polyurethane varnish, 7312 polyurethane curing agent, and butyl acetate, and the mass ratio is 6:1:3; put the release paint evenly In the atomizing spray gun, use the atomizing spray gun to spray the release paint on the combined potting mold, and the release paint is evenly distributed on the surface of the potting mold; put the potting mold in a dry and dust-free...

Embodiment 3

[0045] Such as figure 1 As shown, the potting mold is designed according to the shape of the electrical connector 1 to be potted, and the potting mold includes such as Figure 4 As shown on the left die 2 and as Figure 5 The right mold 3 shown uses the 3D printing manufacturing method to print the potting mold. The material of the potting mold is polylactic acid. After the left mold and the right mold are made, polyimide tape is pasted on the outer surface to connect the two together. It can also be glued together by GD414 silicone rubber; prepare the release paint, the composition of the release paint includes 7385 polyurethane varnish, 7312 polyurethane curing agent, and butyl acetate, and the mass ratio is 6:1:5; put the release paint evenly In the atomizing spray gun, use the atomizing spray gun to spray the release paint on the combined potting mold, and the release paint is evenly distributed on the surface of the potting mold; put the potting mold in a dry and dust-fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com