Continuous coating process for fuel cell membrane electrode (CCM)

A fuel cell membrane and coating process technology, applied in battery electrodes, devices for coating liquid on surfaces, coatings, etc., can solve the problem of uneven distribution of polymer proton conductors, uneven mixing and dispersion of catalyst slurry, and catalyst utilization. rate loss and other problems, to achieve the effect of improving the use efficiency and electrochemical performance, increasing the porosity and catalytic efficiency, and improving the dispersion efficiency and dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

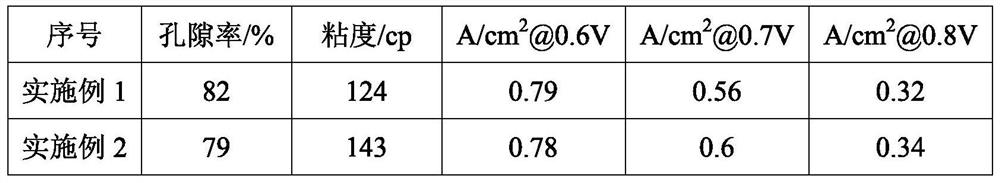

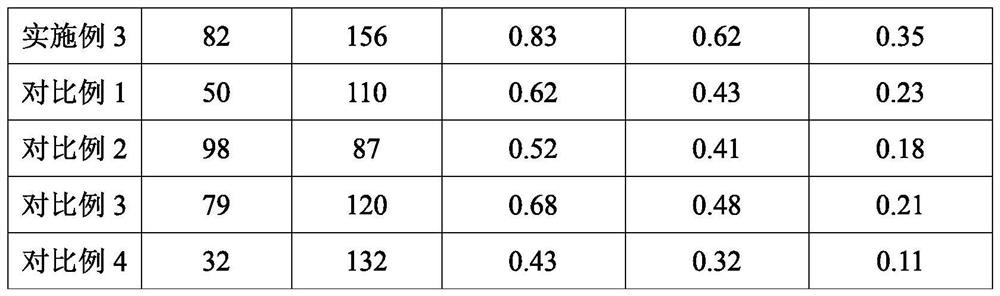

Examples

Embodiment 1

[0030] (1) Take by weighing 10g 5% Nafion resin liquid, 40g Virahol and 1g ammonium bicarbonate and mix together, ultrasonic 10min, ultrasonic frequency is 10Hz, disperses evenly, obtains the colloidal form dispersion liquid that particle size is 20nm;

[0031] (2) Under vacuum anaerobic condition, take by weighing 2g 10% Pt / C solid particles and add in the colloidal dispersion obtained in step (1), first carry out ultrasonic mixing for 10min, then carry out ultrasonic-assisted high-speed stirring and disperse for 15min, the ultrasonic frequency is 50Hz, the stirring speed is 10000RPM. During the ultrasonic-assisted high-speed stirring process, the ultrasonic oscillation equipment adopts high and low temperature water bath circulation to keep the dispersion temperature of the catalyst slurry at 25°C;

[0032] (3) Use roll-to-roll continuous coating equipment to uniformly coat the catalyst slurry prepared by step (2) on the proton exchange membrane, control the dry thickness of ...

Embodiment 2

[0039] (1) Take by weighing 20g20% Nafion resin liquid, 80g Virahol and 8g Polyethylene Glycol and mix together, ultrasonic 10min, ultrasonic frequency is 50Hz, obtains the colloidal form dispersion liquid that particle diameter is 50nm;

[0040] (2) Under vacuum anaerobic condition, take by weighing 30g 90% Pt / C solid particles and add in the colloidal dispersion obtained in step (1), first carry out ultrasonic mixing for 10min, then carry out ultrasonic-assisted high-speed stirring and disperse for 15min, and the ultrasonic frequency is 100Hz, the stirring speed is 20000RPM. During the process of ultrasonic-assisted high-speed stirring, the ultrasonic oscillation equipment adopts high and low temperature water bath circulation to keep the dispersion temperature of the catalyst slurry at 25°C;

[0041] (3) Use roll-to-roll continuous coating equipment to uniformly coat the catalyst slurry prepared by step (2) on the proton exchange membrane, control the dry thickness of the ca...

Embodiment 3

[0048] (1) Take by weighing 15g 10% Nafion resin liquid, 60g isopropanol and 4g lithium carbonate and mix together, ultrasonic 10min, ultrasonic frequency is 80Hz, obtains the colloidal form dispersion liquid that particle size is 50nm;

[0049] (2) Under vacuum anaerobic condition, take by weighing 10g 40% Pt / C solid particle and add in the colloidal dispersion liquid gained in step (1), carry out ultrasonic mixing 10min first, carry out ultrasonic assisted high-speed stirring and disperse 15min again, ultrasonic frequency is 90Hz, the stirring speed is 15000RPM. During the ultrasonic-assisted high-speed stirring process, the ultrasonic oscillation equipment adopts high and low temperature water bath circulation to keep the dispersion temperature of the catalyst slurry at 25°C;

[0050] (3) Use roll-to-roll continuous coating equipment to uniformly coat the catalyst slurry prepared by step (2) on the proton exchange membrane, control the dry thickness of the catalytic layer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com