Preparation method of PDMS in-situ wrinkled antireflection film and preparation method of white organic light-emitting diode

A technology of light-emitting diodes and anti-reflection coatings, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices. It can solve problems such as unsuitable flexible substrates, harsh reaction conditions, and expensive equipment, and achieve improved display quality and cost. Low, soft output light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this example,

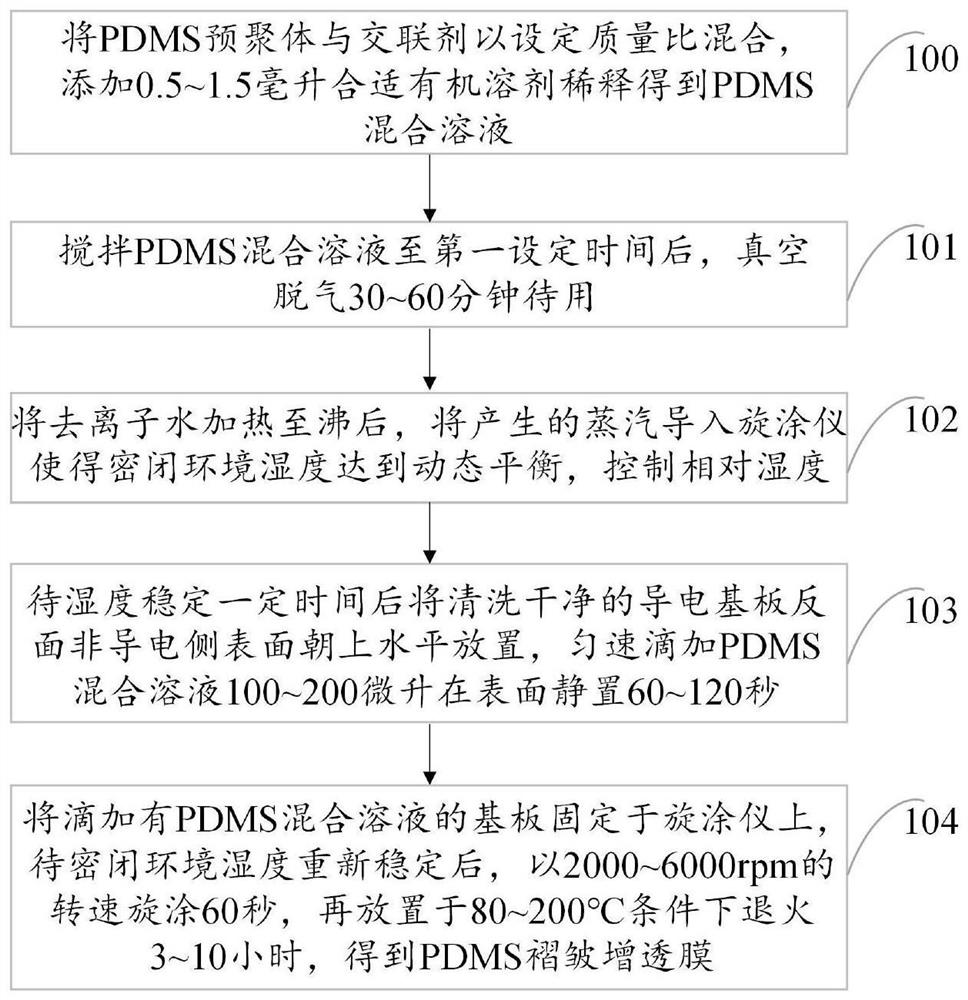

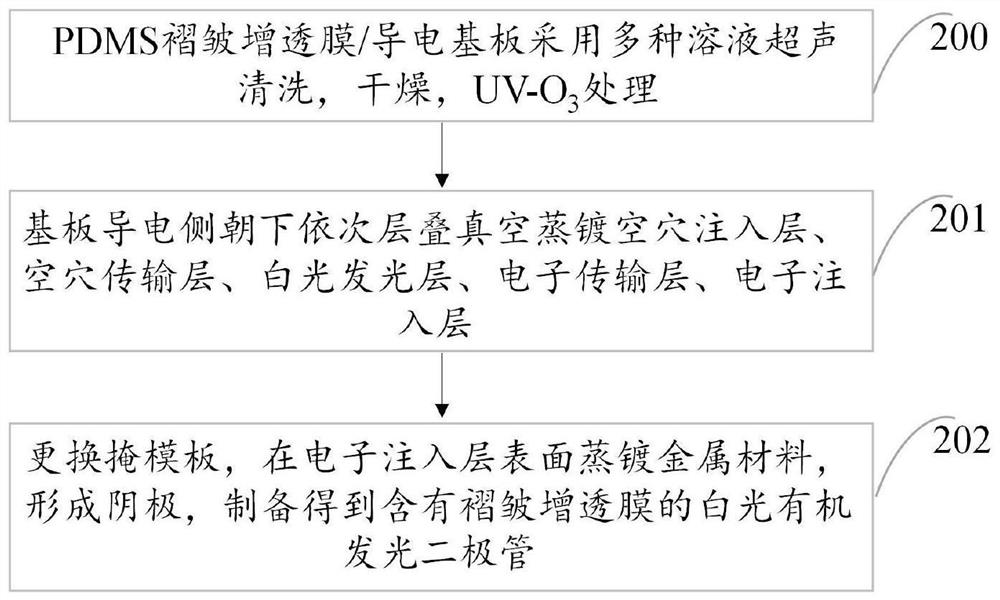

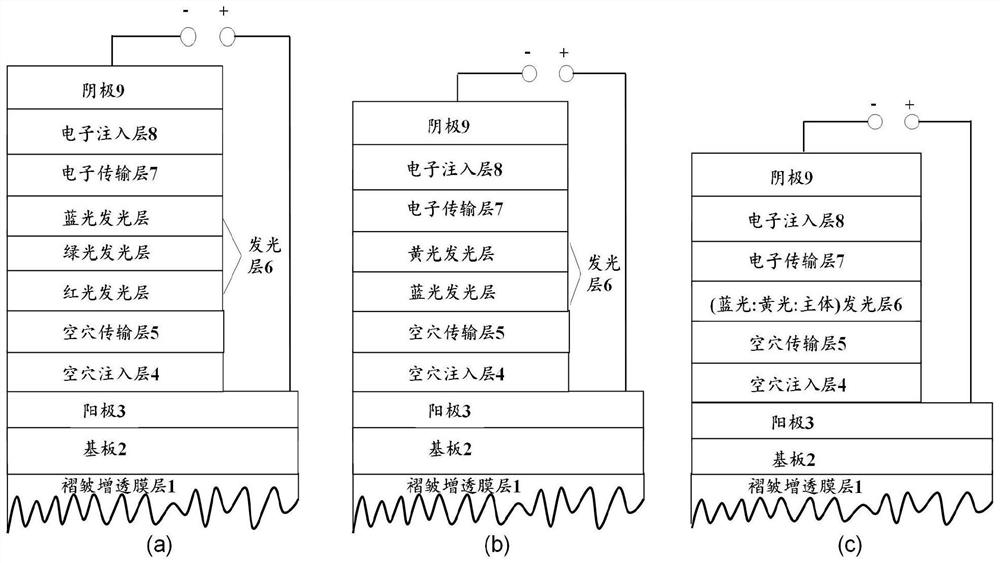

[0065] see figure 1 and figure 2 , a method for preparing a PDMS in-situ wrinkled anti-reflection film and a white light organic light-emitting diode, comprising the steps of:

[0066] Step 100: According to the mass ratio (w / w) of DMS prepolymer and crosslinking agent mixed at 10:1, weigh 3.3g of PDMS prepolymer and PDMS crosslinking agent, and add them into a clean transparent reagent bottle , respectively take 0.5mL, 1.0mL and 1.5mL of chloroform and mix with PDMS solution;

[0067] Step 101: Stir evenly, seal, and place the mixed solution in a moderate vacuum environment for degassing for 1 hour;

[0068] Step 102: After heating the deionized water to boiling, the generated steam is introduced into the spin coater so that the humidity in the airtight environment reaches a dynamic balance, and the relative humidity is controlled to be 75%;

[0069] Step 103: After ultrasonically cleaning the ITO glass substrate with detergent, acetone, deioniz...

Embodiment 2

[0077] This embodiment is basically the same as Embodiment 1, and the special features are:

[0078] In this embodiment, a method for preparing a PDMS in-situ wrinkled anti-reflection film and a white light organic light-emitting diode includes the following steps:

[0079] Step 100: According to the mass ratio (w / w) of DMS prepolymer and crosslinking agent mixed at 10:1, weigh 3.3g of PDMS prepolymer and PDMS crosslinking agent, and add them into a clean transparent reagent bottle , take 1.0mL chloroform and mix it with PDMS solution;

[0080] Step 101 to step 200: this step is the same as that of Embodiment 1;

[0081] Step 201: Place the conductive side of the substrate in step 200 down in a vacuum evaporation chamber to sequentially evaporate various functional layers, including NPB:rubrene (2wt%, 50nm) / BCP (8nm) / Alq3 (30nm) / Liq ( 1nm);

[0082] Step 202: Finally, replace the mask to vapor-deposit cathode metal Al to prepare an electrode cathode layer with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com