Pure-crystalline-phase high-quality-factor nano-sized calcium magnesium titanate ceramic powder and preparation method thereof

A calcium magnesium titanate ceramic with a high quality factor technology, which is applied in the field of material preparation, can solve the problems of limiting the development and application of calcium magnesium titanate ceramic materials, agglomerated crystal phases, large particles, etc., and achieve good particle dispersion and particle size Relatively, the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

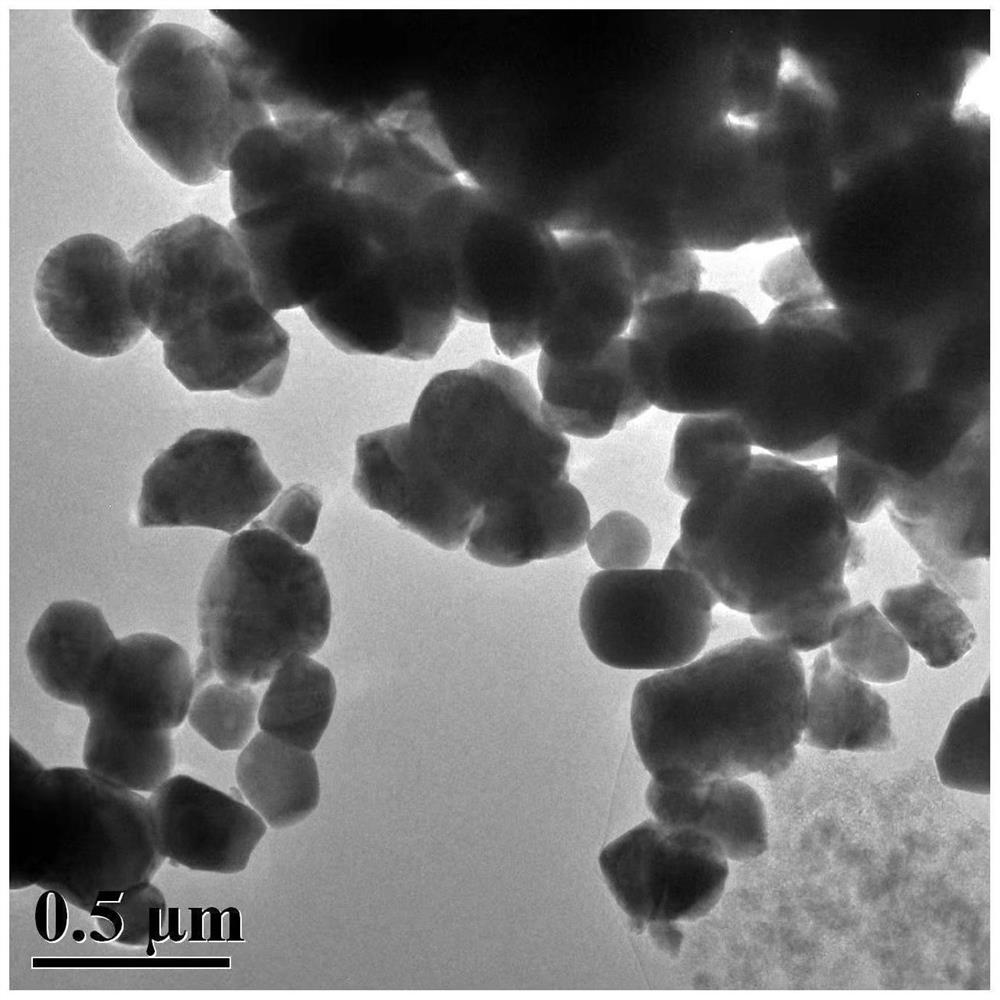

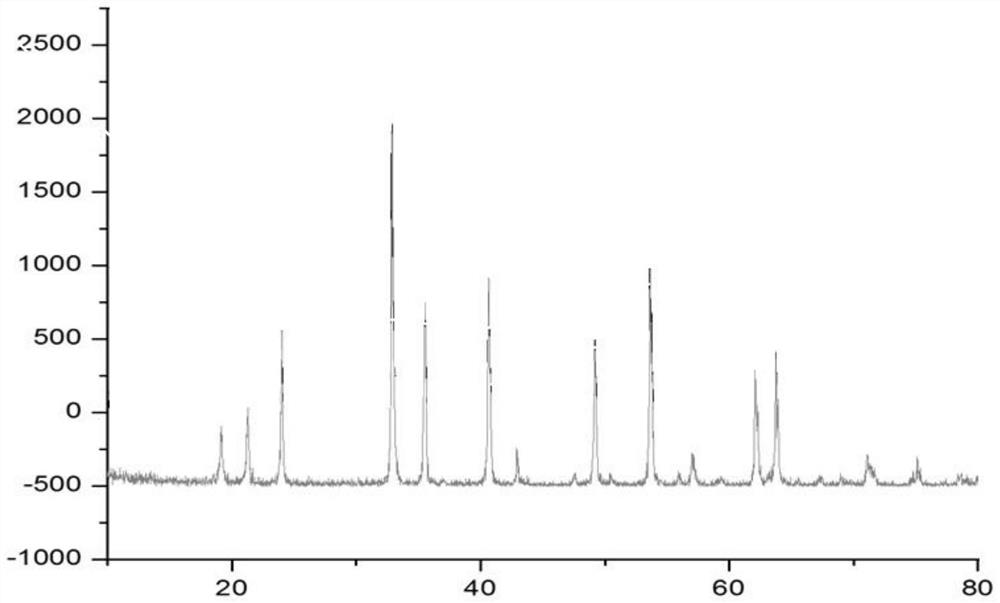

[0027] 10 g of magnesium carbonate, 0.5 g of calcium carbonate and 1.0 g of PEG-10000 were dissolved with 500 ml of water and ethanol mixed solvent (water and organol than 1: 0.1), and 100 ml was stirred with 40 g of titanium tetrachloride after stirring for half an hour. The solution was added to the above solution by a peristaltic pump. After stirring for 12 h, the resulting gel solution product was separated at 11000 rpm to give a gel for 5 minutes, and then washed twice with water and ethanol, and after drying at 80 ° C for 12h after air. After 4 hours by 1100 ° C, the gas pressure is 8.0 MPa gaseous pulverizer, and the cyclone is collected from the powder sample, which can obtain D50 70 nm, pure crystal phase nanometer titanate calcium ceramic powder, dielectric Constant test results are 20.6, and the quality factor can reach 110,000. Its morphology and characteristics Figure 1 - Figure 2 Indicated.

Embodiment 2

[0029] 10 g of oxalic acid, 1 g of calcium chloride and 1.0 g of PEG-40000 were dissolved with 500 ml of water and ethanol mixed solvent (the volume ratio of water and the organol was 1: 0.1), and 100 ml was 10 g of a hydracelide solution of 50 g of chloride solution after stirring for half an hour. The above solution was added to the peristaltic pump. After stirring for 12 h, the resulting gel solution product was separated at 11000 rpm to give a gel for 5 minutes at 11000 rpm, and then washed twice with water and ethanol, after 12 hours of dry 12 hours, After 4 hours of calcination at 900 ° C, D50 is 90 nm, and the pure crystal phase high quality factor nano-sized titanate calcium ceramic powder can be obtained.

Embodiment 3

[0031]10 g of magnesium carbonate, 1 g of calcium carbonate and 1.0 g of PEG-10000 were dissolved with 500 ml of water and ethanol mixed solvent (water and organol than 1: 0.2), and after stirring for half an hour, the above solution was slowly dripped with a peristaltic pump. After adding 400 mL of a titanium titanium tetrachloride solution, after stirring for 12 h, the resulting gel solution product was separated at 8000 rpm to give a gel for 5 minutes, and then washed twice with water and ethanol, dry 100 ° C in the air. After 12 hours, after 4 hours of calcination at 1000 ° C, the gas pressure was 1.0 MPa gaseous pulverizer, the cyclone separator collected the obtained powder sample, which can obtain D50 to 105 nm, pure crystal phase high quality factor nanometer titanate magnesium titanate Calcium ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com