Lithium ion battery negative electrode current collector and preparation method thereof

A technology for lithium-ion batteries and current collectors, applied in battery electrodes, electrode carriers/current collectors, non-aqueous electrolyte battery electrodes, etc., can solve problems such as poor electron transmission performance, low mass ratio, and complicated preparation methods, and achieve simple equipment , reduce the mass ratio, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

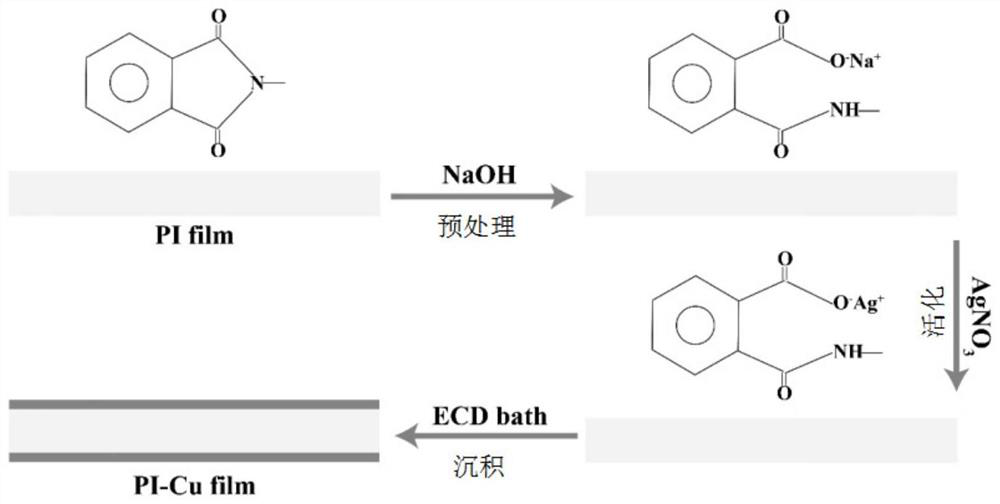

[0044] The present invention also provides a preparation method of a lithium ion battery negative electrode current collector, comprising the steps of:

[0045] S1, immersing the polyimide film in a concentrated sodium hydroxide solution to obtain a pretreated polyimide film;

[0046] S2, immersing the pretreated polyimide film in a silver nitrate solution to obtain an activated polyimide film;

[0047] S3, immersing the activated polyimide film in an electroless copper plating solution and contacting it for a predetermined time to obtain a lithium ion battery negative electrode current collector.

[0048] Specifically, the present invention prepares polyimide copper-plated film by electroless plating and mainly comprises three steps: pretreatment, activation and copper deposition (as figure 1 shown). In step S1, after the polyimide is pretreated with sodium hydroxide, the imide rings on its surface are opened and hydrolyzed to form carboxyl groups, and the generated carboxy...

Embodiment 1

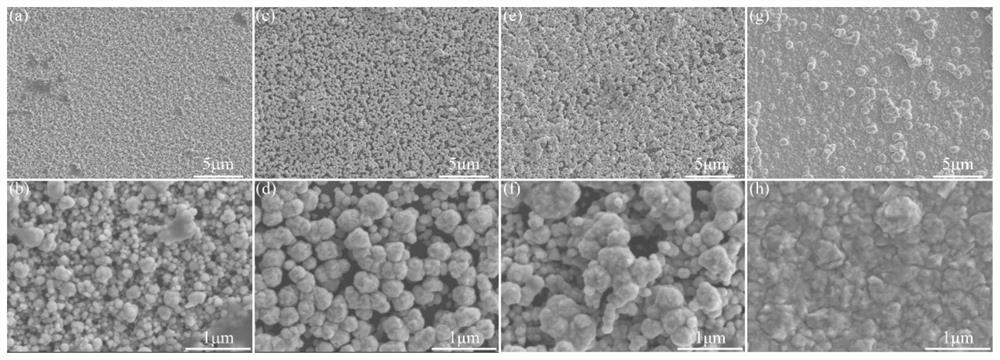

[0059] 1. Preparation of current collector: First, immerse the polyimide film in a concentrated sodium hydroxide solution (15% by mass) for 60 minutes, then rinse it with deionized water and then immerse it in a silver nitrate solution (1g / L) 10 minutes, and finally immersed in the electroless copper plating solution for 5 minutes to obtain a polyimide copper plating film. Wherein, the electroless copper plating solution is copper sulfate pentahydrate (15g / L), potassium sodium tartrate (14g / L), disodium edetate (20g / L), sodium hydroxide (15g / L), Potassium ferricyanide (10mg / L), 2,2-bipyridine (20mg / L) and formaldehyde solution (15mL / L) were dissolved in deionized water at room temperature to obtain the lithium ion battery negative electrode current collector.

[0060] 2. Preparation of lithium titanate electrode: First, the active material lithium titanate, carbon black conductive agent and polymer binder polyvinylidene fluoride are mixed and stirred with an appropriate amount...

Embodiment 2

[0063] On the basis of Example 1, the time of immersion in the electroless copper plating solution was adjusted to 10, and the rest of the preparation process parameters and process steps were the same as in Example 1, and the lithium ion battery negative electrode current collector, lithium titanate electrode and button battery were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com