Chromium-free low-temperature curing water-based zinc-aluminum coating as well as preparation method and application thereof

A zinc-aluminum coating, water-based technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as cracking, high energy consumption, and loss of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a preparation method for the chrome-free low-temperature curing water-based zinc-aluminum coating described in the above technical solution, comprising the following steps:

[0051] mixing the first co-solvent and thickener, and mixing the obtained first mixture, dispersant, defoamer and zinc-aluminum antirust powder to obtain the zinc-aluminum paste;

[0052] Mixing water, a second co-solvent and a passivator to obtain a second mixture;

[0053] Mixing the water-soluble silicone resin and the curing accelerator to obtain a third compound;

[0054] The second mixture and the third mixture are mixed to perform a hydrolysis reaction, and the obtained hydrolyzed material solution is mixed with an aqueous nano inorganic silicate to perform a hybridization reaction to obtain the aqueous silicon slurry.

[0055] In the present invention, each component in the preparation method is consistent with each component in the chromium-free low-tem...

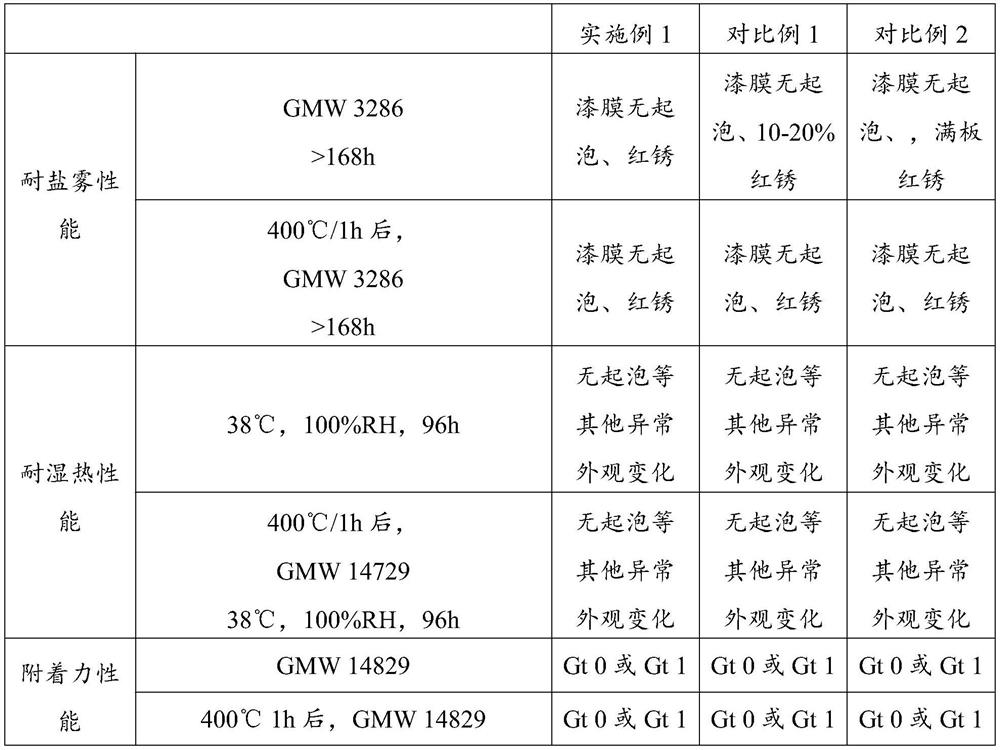

Embodiment 1

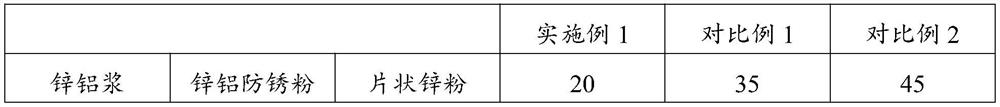

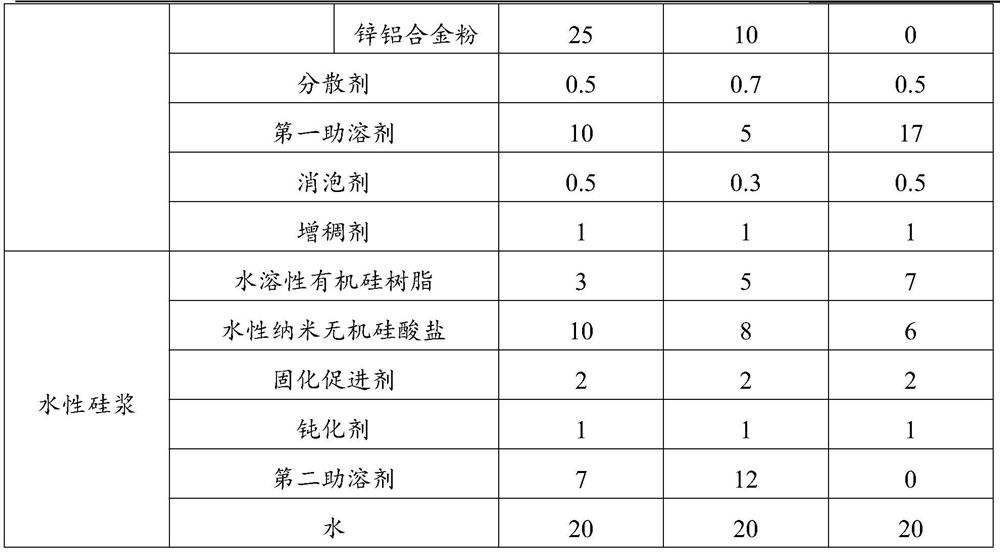

[0092] Carry out the preparation of chromium-free low-temperature curing water-based zinc-aluminum coating according to the substance consumption in Table 1:

[0093] Mix the first co-solvent and thickener at 25°C, and mix the obtained first mixture, dispersant, defoamer and zinc-aluminum antirust powder at 30°C to obtain the zinc-aluminum paste;

[0094] Mixing water, a second co-solvent and a passivating agent at 25°C to obtain a second mixture;

[0095] Mixing the water-soluble silicone resin and the curing accelerator to obtain a third compound;

[0096] Mix the second mixture with the third mixture, stir at room temperature for 3.5 hours to carry out a hydrolysis reaction, mix the obtained hydrolyzed feed solution with aqueous nano-inorganic silicate, and stir at room temperature for 1.5 hours to carry out a hybridization reaction to obtain the Water-based silicon paste;

[0097] The obtained zinc-aluminum paste and water-based silicon paste are mixed according to a mas...

Embodiment 2

[0109] Carry out the preparation of chromium-free low-temperature curing water-based zinc-aluminum coating according to the substance consumption of table 3:

[0110] Mix the first co-solvent and thickener at 25°C, and mix the obtained first mixture, dispersant, defoamer and zinc-aluminum antirust powder at 30°C to obtain the zinc-aluminum paste;

[0111] Mixing water, a second co-solvent and a passivating agent at 25°C to obtain a second mixture;

[0112] Mixing the water-soluble silicone resin and the curing accelerator to obtain a third compound;

[0113] Mix the second mixture with the third mixture, stir at room temperature for 3 hours to carry out hydrolysis reaction, mix the obtained hydrolyzed feed solution with aqueous nano-inorganic silicate, stir at room temperature for 1 hour to carry out hybridization reaction, and obtain the water-based silicon pulp;

[0114] The obtained zinc-aluminum paste and water-based silicon paste are mixed according to a mass ratio of 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com