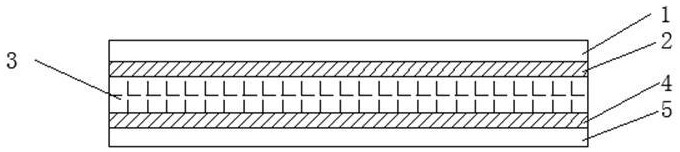

Wall panel composed of composite boards and preparation method of wall panel

A technology for composite panels and wall panels, applied in chemical instruments and methods, synthetic resin layered products, household walls, etc., can solve the problems of noise pollution, failure to meet use requirements, and poor fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

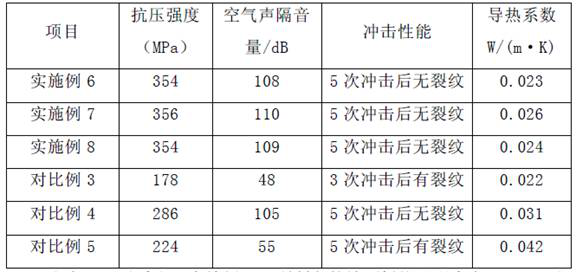

Examples

Embodiment 1

[0041] This embodiment provides a temperature control material, which is made by the following steps:

[0042] Step B1, put kaolin in a muffle furnace at 800°C for 2 hours, then cool naturally to room temperature to obtain metakaolin; stir and mix metakaolin and cetyltrimethylammonium bromide solution with a mass fraction of 2% After 20 minutes, add sodium hydroxide solution with a mass fraction of 40% to adjust the pH value to 12.0, then raise the temperature to 90°C, perform ultrasonic treatment at a frequency of 40kHz for 3h, then filter with suction, wash the filter cake until the washing liquid is neutral, and dry at 100°C 2h, roasting at 540°C for 5h to obtain the wall material, the dosage ratio of metakaolin and cetyltrimethylammonium bromide solution is 3.5g: 60mL;

[0043] Step B2: Add paraffin wax and stearic acid to a three-necked flask, treat in a constant temperature water bath at 75°C for 20 minutes, then add wall materials, heat in a water bath at 90°C, stir mag...

Embodiment 2

[0045] This embodiment provides a temperature control material, which is made by the following steps:

[0046] Step B1, put kaolin in a muffle furnace at 800°C for 2 hours, then cool naturally to room temperature to obtain metakaolin; stir and mix metakaolin and cetyltrimethylammonium bromide solution with a mass fraction of 2% After 30 minutes, add sodium hydroxide solution with a mass fraction of 40% to adjust the pH value to 12.0, then raise the temperature to 90°C, perform ultrasonic treatment at a frequency of 50kHz for 3h, then filter with suction, wash the filter cake until the washing liquid is neutral, and dry at 100°C 2h, roasted at 540°C for 5h to obtain the wall material, the dosage ratio of metakaolin and cetyltrimethylammonium bromide solution is 4.2g: 60mL;

[0047] Step B2: Add paraffin wax and stearic acid into a three-necked flask, treat in a constant temperature water bath at 75°C for 20 minutes, then add wall materials, heat in a water bath at 90°C, stir ma...

Embodiment 3

[0049] This embodiment provides a polyurethane foam board, which is made by the following steps:

[0050] Step A11, prepare the following raw materials in parts by weight: 85 parts of polyether polyol, 75 parts of polyester polyol, 25 parts of isophorone diisocyanate, 8 parts of the temperature control material of Example 1, 10 parts of metal filler, foaming agent 4 parts, 8 parts of 2,2-dimethylol butyric acid;

[0051] Step A12, prepare the foam board frame mold, put metal fillers into the mold, and arrange the metal fillers in a circular array shape, mix polyether polyol and polyester polyol evenly, and then add foaming agent and chain extender , temperature control material, stir evenly at room temperature, finally add isophorone diisocyanate, stir evenly to get the premix, then inject the premix into the foam board frame mold, the injection pressure is 14MPa, the injection time is 10s, and at 40 Foaming and curing at ℃ for 10 minutes, trimming the leftovers, and obtainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com