A kind of nanometer tool coating and preparation method thereof

A tool and coating technology, applied in the field of nano-tool coating and its preparation, to increase the specific surface area and surface energy, reduce the internal stress of the coating, and enhance the bending/fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

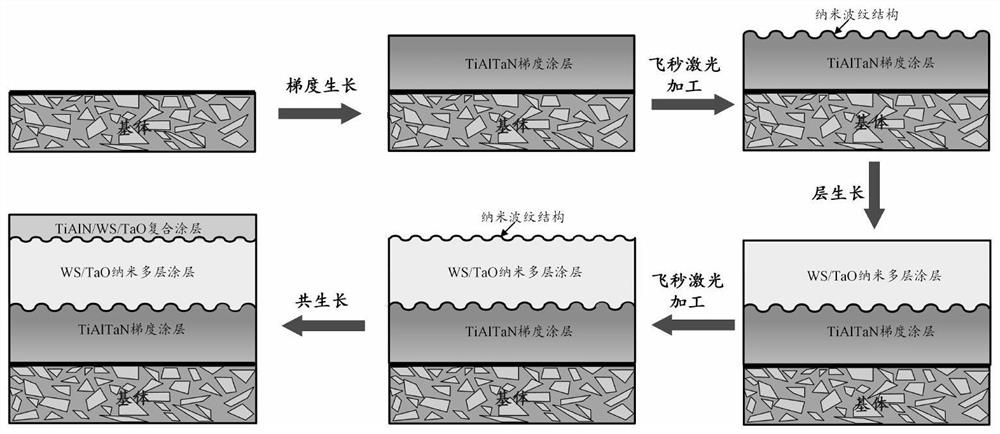

[0039] refer to figure 2 As shown, a nano-tool coating and preparation method thereof, the specific steps are as follows:

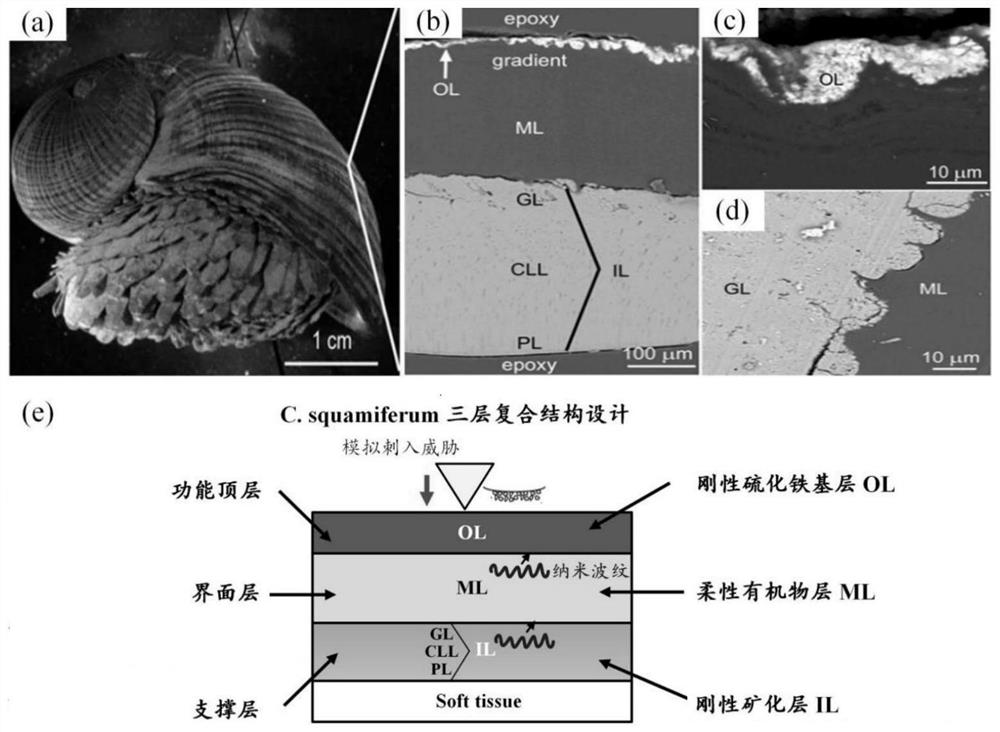

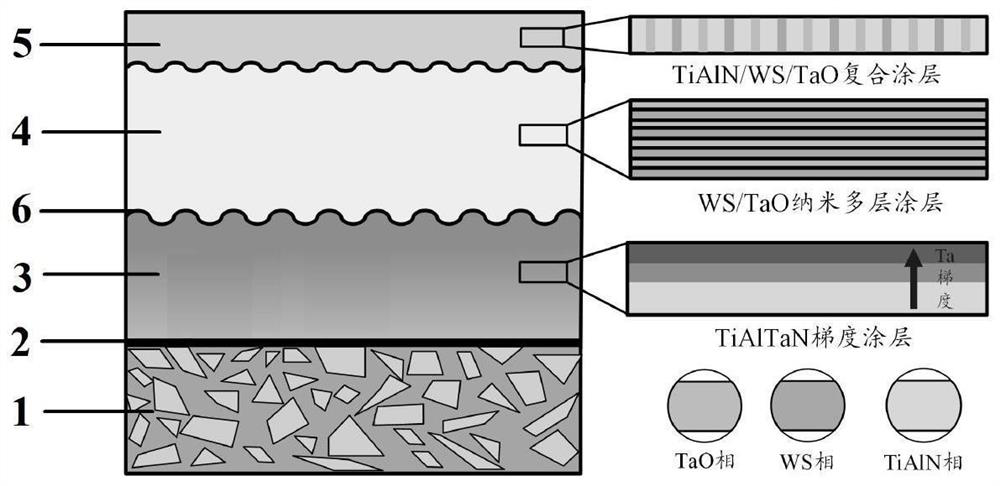

[0040] The base material of the tool is WC / Co cemented carbide, and the multi-scale bionic structure of the tool coating is designed according to the microstructure of C. squamiferum, that is, three layers of micron-scale are formed by sputtering target particle gradient growth, layer growth and co-growth. Functionally graded coating, and the nano-scale corrugated structure is introduced between the interfaces of each layer to control the bonding strength between layers, so that the overall tool coating presents a "hard-tough-hard" three-layer composite structure. Its specific preparation process steps are as follows:

[0041] (1) Matrix grinding and polishing, ultrasonic cleaning: Prepare metallographic samples on the surface of the tool matrix on an automatic metallographic grinding machine, then grind with 1000# sandpaper with absolute ethanol, and t...

Embodiment 2

[0048] refer to figure 2 As shown, a nano-tool coating and preparation method thereof, the specific steps are as follows:

[0049] The base material of the tool is high-speed steel, and the multi-scale bionic structure of the tool coating is designed according to the microstructure of C. squamiferum, that is, a three-layer functionally graded coating with a micron scale is formed through the gradient growth, layer growth and co-growth of the sputtering target material. , and the nano-scale corrugated structure is introduced between the interfaces of each layer to control the interlayer bonding strength, so that the overall tool coating presents a "hard-tough-hard" three-layer composite structure. Its specific preparation process steps are as follows:

[0050] (1) Matrix grinding and polishing, ultrasonic cleaning: Prepare metallographic samples on the surface of the tool matrix on an automatic metallographic grinding machine, then grind with 1000# sandpaper with absolute eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com