Low-temperature curing low-dielectric high-toughness cyanate ester resin and preparation method thereof

A cyanate resin, low dielectric technology, applied in the fields of organic polymer synthesis and thermosetting resin modification, can solve the problems of poor dimensional stability, high residual stress of products, and high curing temperature of cyanate resin, and achieve excellent Mechanical properties, fast curing rate, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

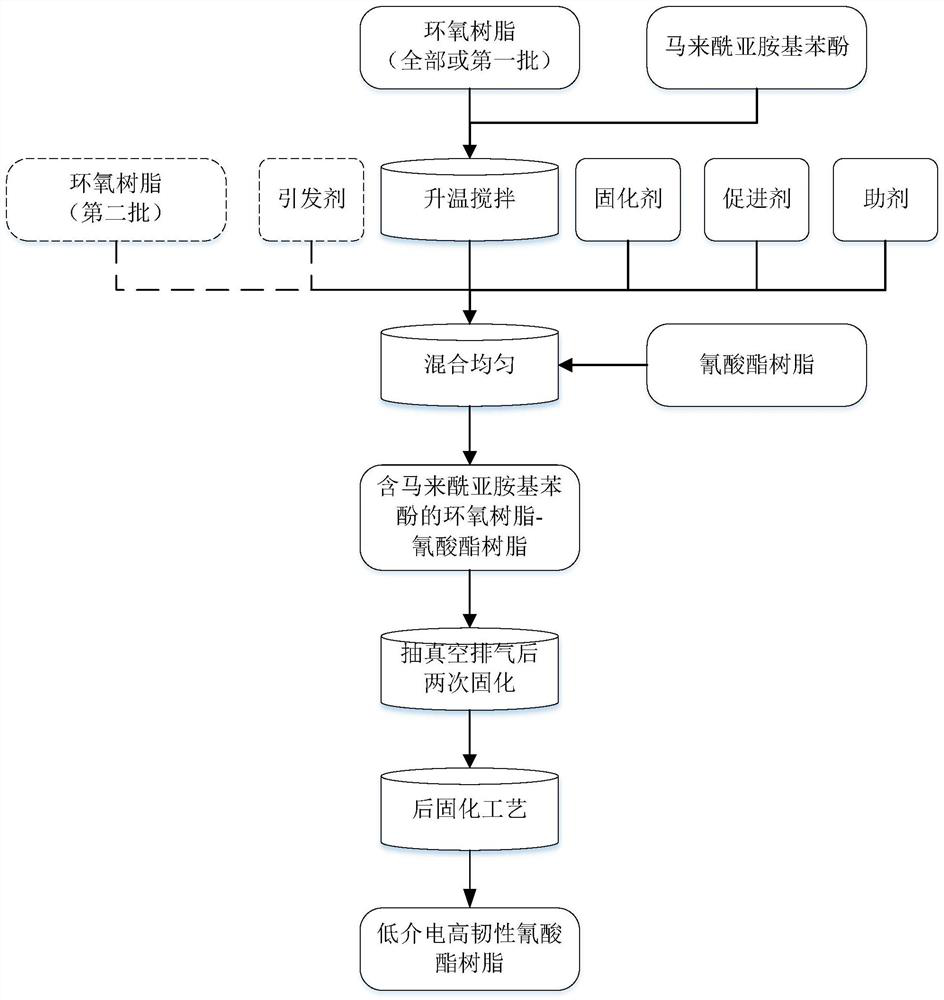

Method used

Image

Examples

Embodiment 1

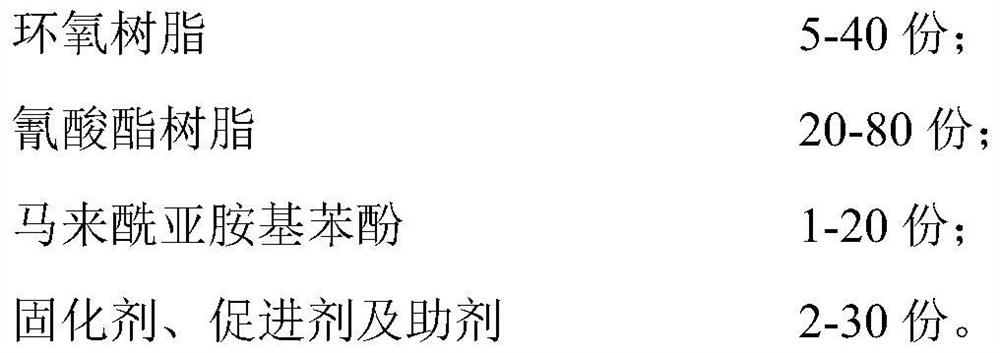

[0038] Take 20 parts of bisphenol A epoxy resin E51, add 5 parts of 4-maleimidophenol (structural formula 2), add 5 parts of dicyandiamide, 3 parts of substituted urea, 1 part of 9920 defoamer, and stir well Finally, add 16 parts of E20 epoxy resin, add 50 parts of bisphenol A type cyanate (CE01), stir and mix evenly at 90°C, then pour it into a mold at 100°C, vacuumize for 15 minutes, and then heat it at 90°C, 110°C ℃ for 2 hours each, and 130 ℃ for 4 hours to obtain low-dielectric and high-toughness cyanate ester resin.

[0039] The dielectric and mechanical properties of the prepared cyanate resin are listed in Table 1.

Embodiment 2

[0041] Take 20 parts of bisphenol A type epoxy resin E51, add 2 parts of 4-maleimide phenol (structural formula 2), add 2 parts of m-maleimido phenol (structural formula 1), add 1 part of ortho Position 4-maleimidophenol (structural formula 3), add 5 parts of dicyandiamide, 1 part of substituted urea, 0.5 part of 530 defoamer, add 1 part of free radical initiator tert-butyl peroxybenzoate, stir After uniformity, add 15 parts of E20 epoxy resin, add 50 parts of bisphenol A type cyanate (CE01), stir and mix evenly at 90 ° C, then pour into a mold at 100 ° C, vacuumize for 15 minutes, and then at 90 ° C, Keep at 110°C for 2 hours each, and at 130°C and 180°C for 4 hours each to obtain a low-dielectric and high-toughness cyanate ester resin.

[0042] The dielectric and mechanical properties of the prepared cyanate resin are listed in Table 1.

Embodiment 3

[0044] Take 9 parts of bisphenol A epoxy resin E51, add 3 parts of 4-maleimide phenol (structural formula 2), add 4 parts of dicyandiamide, 3 parts of substituted urea, 1 part of 530 defoamer, and stir well Finally, add 80 parts of bisphenol A cyanate (CE01), stir and mix evenly at 90°C, then pour into a mold at 100°C, vacuumize for 15 minutes, then keep at 80°C, 115°C for 4 hours, and at 140°C 6h, you can get low dielectric high toughness cyanate ester resin.

[0045] The dielectric and mechanical properties of the prepared cyanate resin are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com