Composite coating agent for ammonium perchlorate ultrafine particles and preparation method thereof

A technology of composite coating agent and ultrafine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

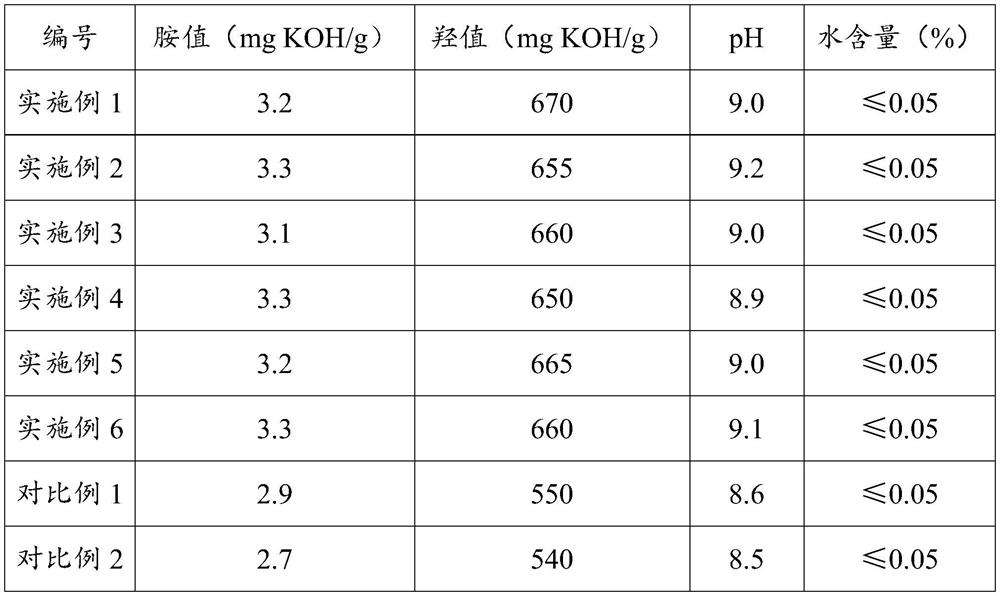

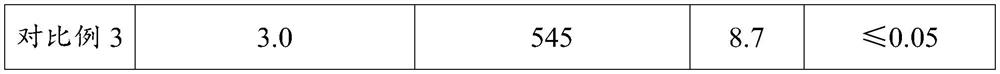

Examples

Embodiment 1

[0024] A composite coating agent for ammonium perchlorate superfine particles is composed of 100 parts by weight of polyalkyl sodium sulfate, 7.0 parts by weight of triethanolamine and 1.5 parts by weight of isopropanolamine.

[0025] The polyalkyl sodium sulfate in this embodiment can be any one of R=12-16.

Embodiment 2

[0027] A composite coating agent for ammonium perchlorate superfine particles, which consists of 100 parts of polyalkyl sodium sulfate, 7.0 parts of triethanolamine and 2.0 parts of isopropanolamine.

[0028] The polyalkyl sodium sulfate in this embodiment can be any one of R=12-16.

Embodiment 3

[0030] A composite coating agent for ammonium perchlorate superfine particles, which consists of 100 parts of polyalkyl sodium sulfate, 7.0 parts of triethanolamine and 2.5 parts of isopropanolamine.

[0031] The polyalkyl sodium sulfate in this embodiment can be any one of R=12-16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com