Chitosan/biochar composite aerogel ball as well as preparation method and application thereof

A composite airgel and composite hydrogel technology, applied in the field of chitosan/biochar composite airgel balls, to achieve the effects of simple and easy raw materials, superior adsorption performance, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

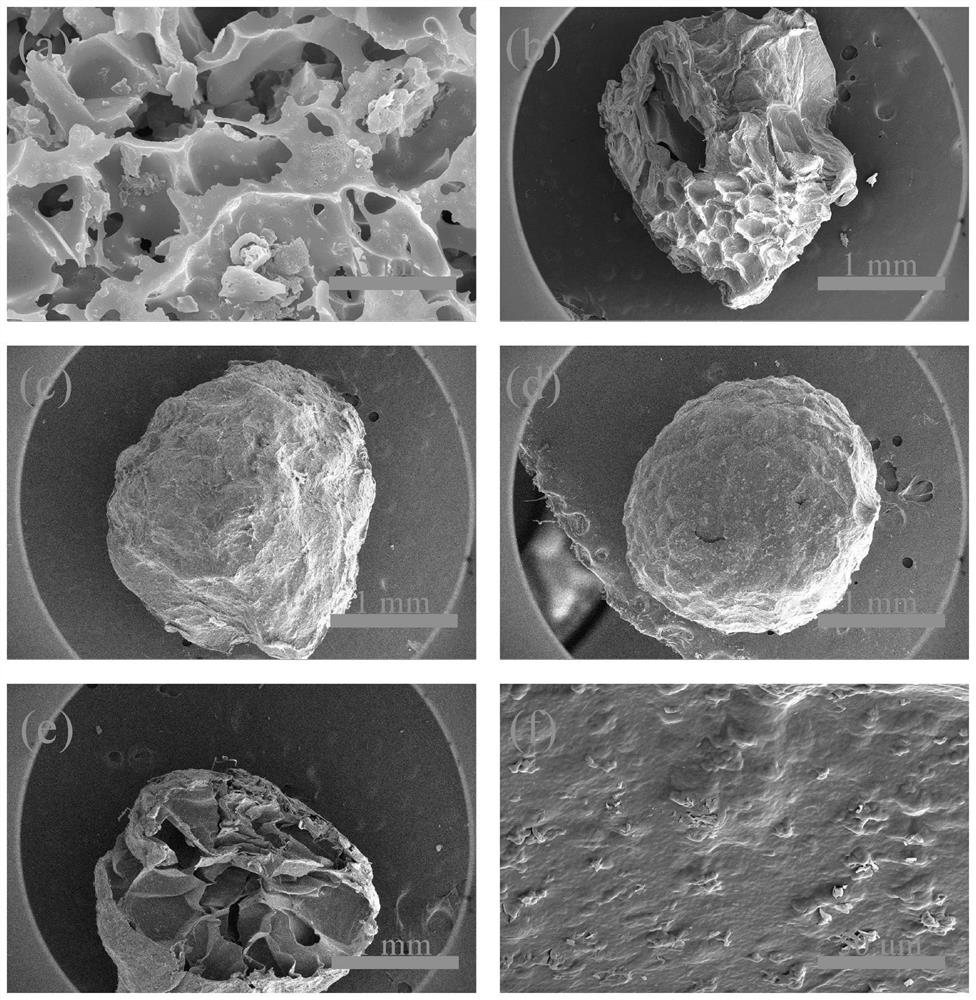

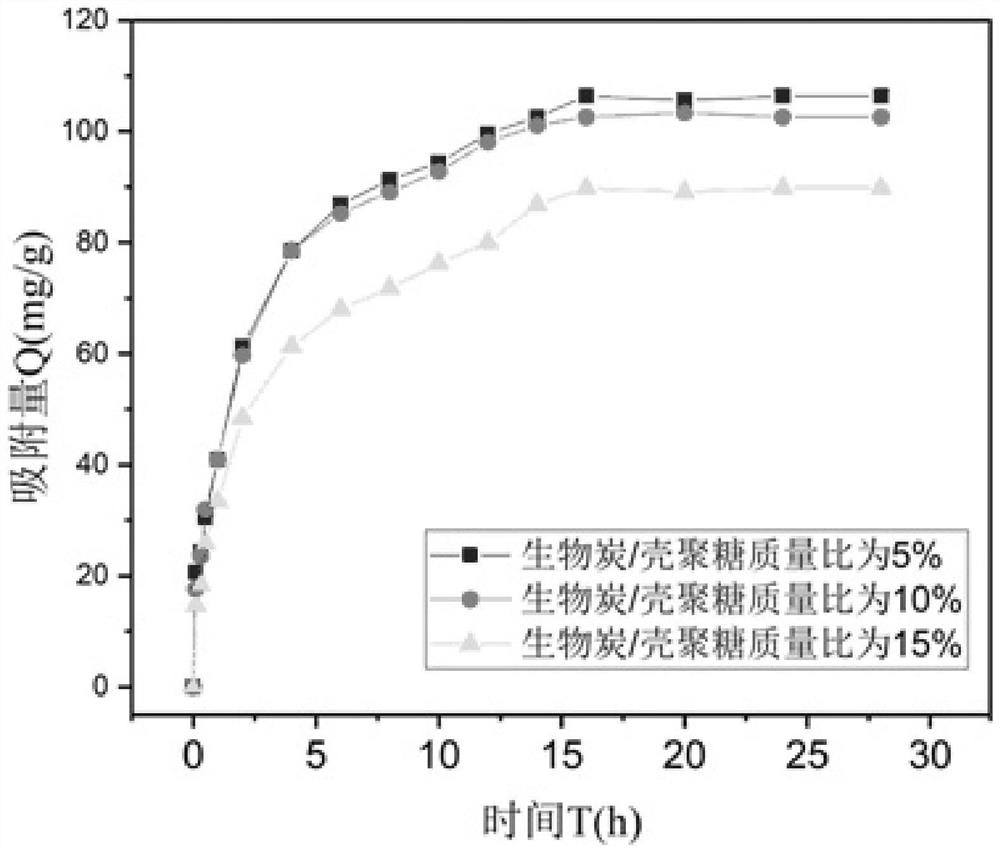

[0034] Embodiment 1: a kind of preparation method of chitosan / biochar composite airgel ball, its preparation process comprises: first utilize potassium hydroxide activation and high-temperature pyrolysis biomass corn cob to prepare biochar, then dissolve chitosan In the acetic acid solution, add the pre-prepared biochar and the cross-linking agent epichlorohydrin, fully disperse in the chitosan matrix, and then drop it into the alkaline coagulant through a syringe pump at an even speed to obtain The formed chitosan / biochar composite hydrogel is finally vacuum freeze-dried to make chitosan / biochar composite airgel balls;

[0035] The specific steps are:

[0036] (1) Prepare biochar; wash the surface of the collected biomass corncobs, dry them for use, mix 1.0g of biomass corncobs with 2.0g of potassium hydroxide solid and put them into a porcelain boat (50*20*20mm) , keep pyrolysis in a nitrogen medium in a tube furnace at 600°C (heating rate 4°C / min) for 1h, and then cool dow...

Embodiment 2

[0043]Embodiment 2: a kind of preparation method of chitosan / biochar composite airgel ball, comprises following preparation steps:

[0044] (1) Preparation of biochar; rinse the surface of the collected biomass corncobs, and dry them for later use. Mix 1.0g of biomass corn cob with 2.0g of potassium hydroxide solid and put it into a porcelain boat (50*20*20mm), keep the heat in a 600°C tube furnace (heating rate of 4°C / min) in a nitrogen medium Solution for 1h, then cool down naturally. The resulting pyrolysis product is washed (deionized water and 95% ethanol solution), ground and dried to obtain porous biochar;

[0045] (2) prepare chitosan / biochar composite airgel ball;

[0046] 1) Add 0.2g chitosan to 3.8mL acetic acid solution (2wt.%), stir until completely dissolved to obtain a 5% chitosan solution;

[0047] 2) Add 0.02 g of biochar and 0.1 g of epichlorohydrin to the above chitosan solution according to a certain ratio (the mass ratio of biochar / chitosan is 10%), and...

Embodiment 3

[0052] (1) prepare biochar;

[0053] Rinse the surface of the collected biomass corncobs and dry them for later use. Mix 1.0g of biomass corn cob with 2.0g of potassium hydroxide solid and put it into a porcelain boat (50*20*20mm), keep the heat in a 600°C tube furnace (heating rate of 4°C / min) in a nitrogen medium Solution for 1h, then cool down naturally. The resulting pyrolysis product is washed (deionized water and 95% ethanol solution), ground and dried to obtain porous biochar;

[0054] (2) prepare chitosan / biochar composite airgel ball;

[0055] 1) Add 0.2g chitosan to 3.8mL acetic acid solution (2wt.%), stir until completely dissolved to obtain a 5% chitosan solution;

[0056] 2) Add 0.03 g of biochar and 0.1 g of epichlorohydrin to the above chitosan solution according to a certain ratio (the mass ratio of biochar / chitosan is 15%), and mix by ultrasonication for 3 hours at 65° C.;

[0057] 3) After the above mixed solution is cooled to room temperature, add (5mL) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com