Cyclodextrin derivative and preparation method thereof

A technology of cyclodextrin and derivatives, which is applied in the field of organic polymer compounds, can solve the problems of long time-consuming dissolution, affecting the use of materials, and decreasing cleanliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

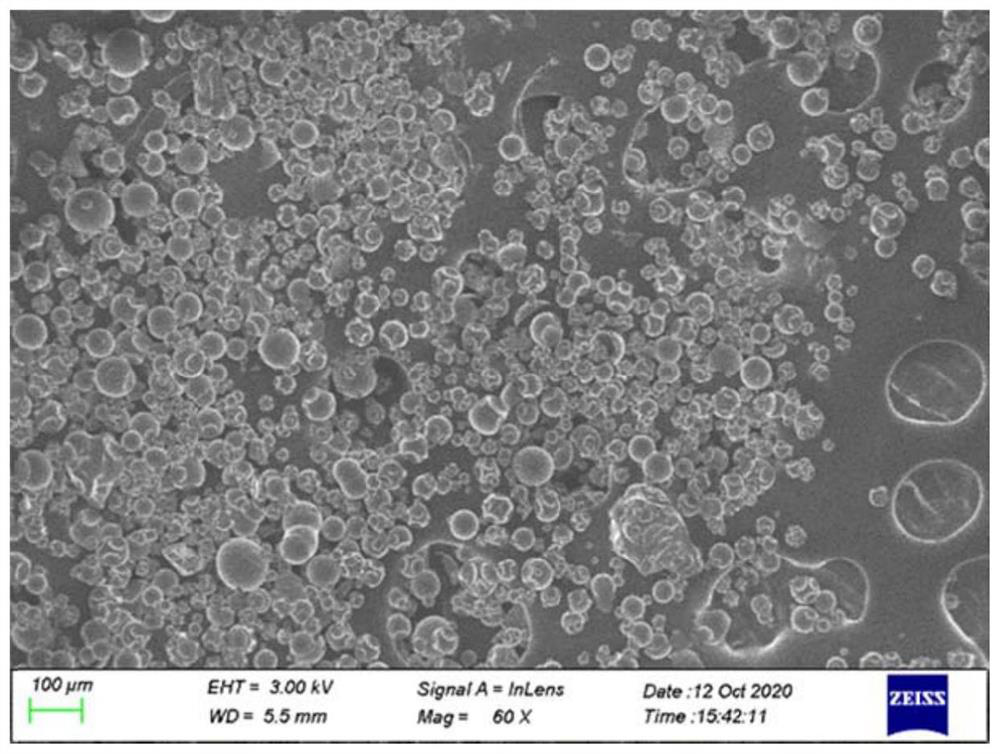

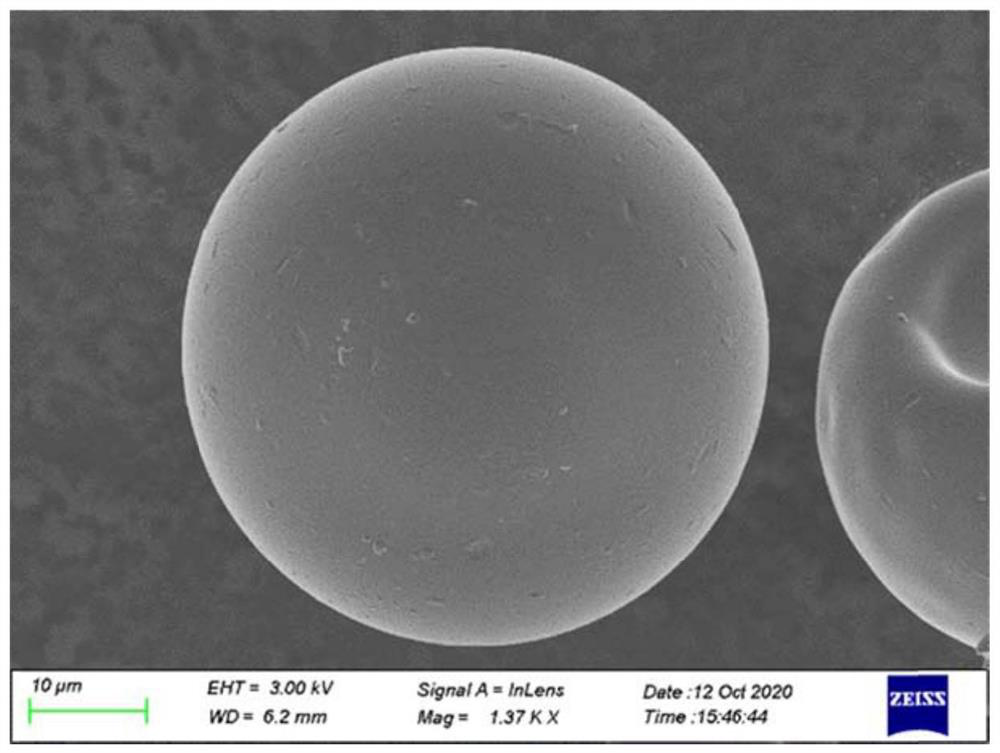

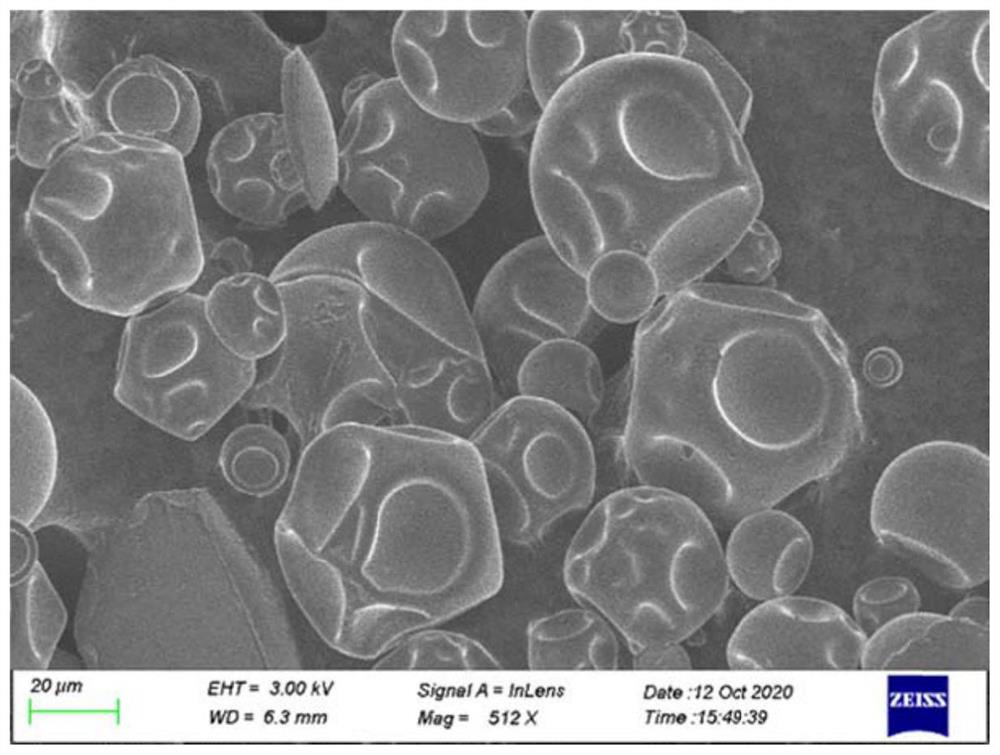

Image

Examples

Embodiment 1

[0042] A. Add 200kg of deionized water, 30kg of β-cyclodextrin, 33.5kg of 1,4-butane sultone, and 8.75kg of sodium hydroxide into a 300L reactor, raise the temperature to 70°C and stir for 24 hours. The pH of the detection system is no longer Decrease, stop the reaction and cool down to room temperature. Add 30% hydrochloric acid to adjust the pH to 7. Add 2.5 kg of powdered activated carbon and continue to stir for 3 hours to carry out decolorization. After the decolorization is completed, remove the activated carbon by filtration to obtain the crude product liquid of sodium sulfobutylbeta cyclodextrin.

[0043] B. The crude product liquid is removed by ultrafiltration to remove macromolecular impurities, and nanofiltration (molecular weight cut-off: 1500) to remove small molecule impurities to obtain a refined solution of sulfobutylbeta cyclodextrin sodium, and determine sulfobutylbeta cyclodextrin by weight loss on drying The solid content in the sodium refined solution is...

Embodiment 2

[0053] A. Add 200kg of deionized water, 30kg of β-cyclodextrin, 33.5kg of 1,4-butane sultone, and 8.75kg of sodium hydroxide into a 300L reactor, raise the temperature to 70°C and stir for 24 hours. The pH of the detection system is no longer Decrease, stop the reaction and cool down to room temperature. Add 30% hydrochloric acid to adjust the pH to 7. Add 2.5 kg of powdered activated carbon and continue to stir for 3 hours to carry out decolorization. After the decolorization is completed, remove the activated carbon by filtration to obtain the crude product liquid of sodium sulfobutylbeta cyclodextrin.

[0054] B. The crude product liquid is removed by ultrafiltration to remove macromolecular impurities, and nanofiltration (molecular weight cut-off: 1500) to remove small molecule impurities to obtain a refined solution of sulfobutylbeta cyclodextrin sodium, and determine sulfobutylbeta cyclodextrin by weight loss on drying The solid content in the sodium refined solution is...

Embodiment 3

[0060] A. Add 200kg of deionized water, 30kg of β-cyclodextrin, 33.5kg of 1,4-butane sultone, and 8.75kg of sodium hydroxide into a 300L reactor, raise the temperature to 70°C and stir for 24 hours. The pH of the detection system is no longer Decrease, stop the reaction and cool down to room temperature. Add 30% hydrochloric acid to adjust the pH to 7. Add 2.5 kg of powdered activated carbon and continue to stir for 3 hours to carry out decolorization. After the decolorization is completed, remove the activated carbon by filtration to obtain the crude product liquid of sodium sulfobutylbeta cyclodextrin.

[0061]B. The crude product liquid is removed by ultrafiltration to remove macromolecular impurities, and nanofiltration (molecular weight cut-off: 1500) to remove small molecule impurities to obtain a refined solution of sulfobutylbeta cyclodextrin sodium, and determine sulfobutylbeta cyclodextrin by weight loss on drying The solid content in the sodium refined solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com