Protective coating capable of resisting erosion of solid particles and preparation method of protective coating

A technology of protective coating and solid particles, which is applied in the field of protective coatings against erosion of solid particles and its preparation, and can solve the problem of poor adhesion of aero-engine substrates, which affects the anti-erosion performance of coatings, and cannot play an anti-erosion role. Effectiveness and other issues, to achieve reliable solid particle erosion protection performance, avoid spalling failure, and facilitate large-area uniform deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

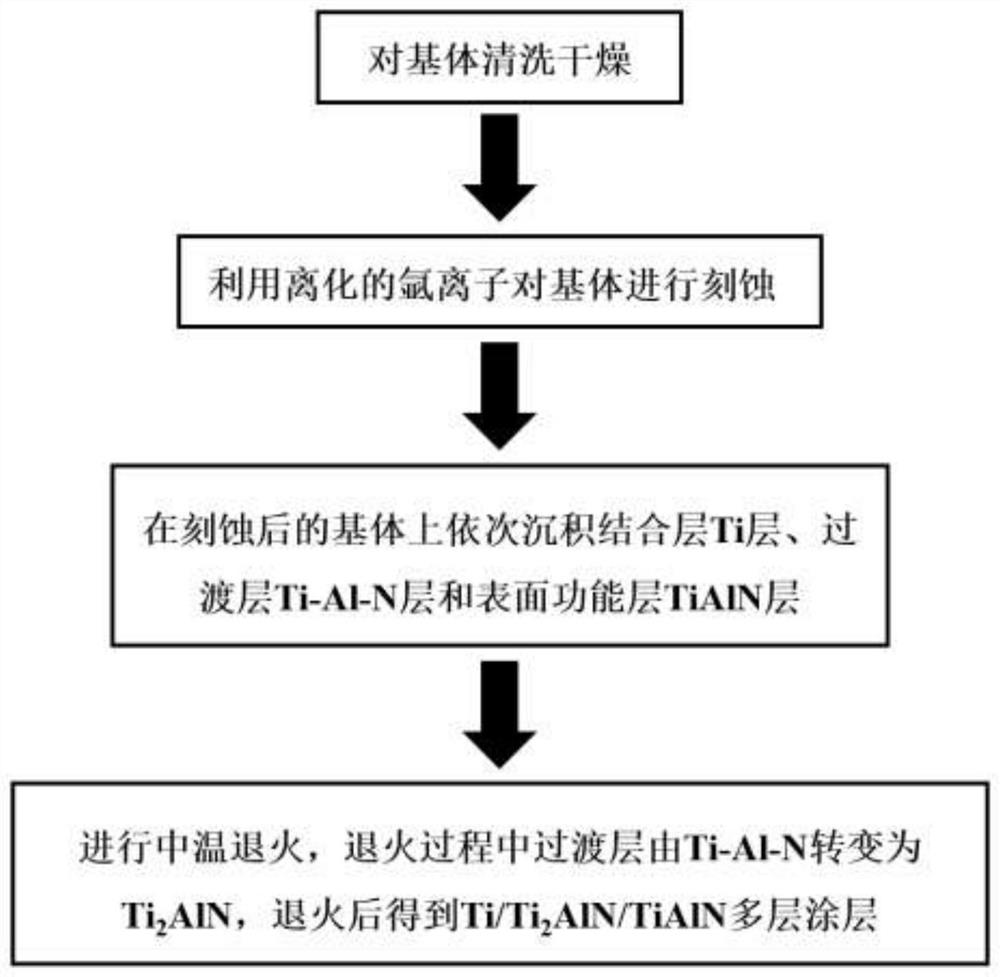

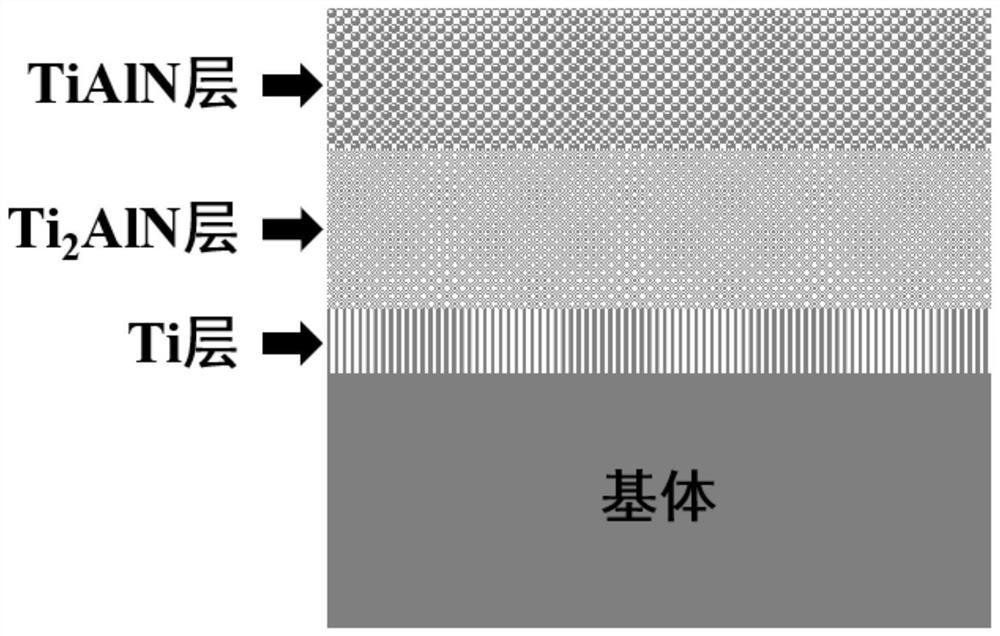

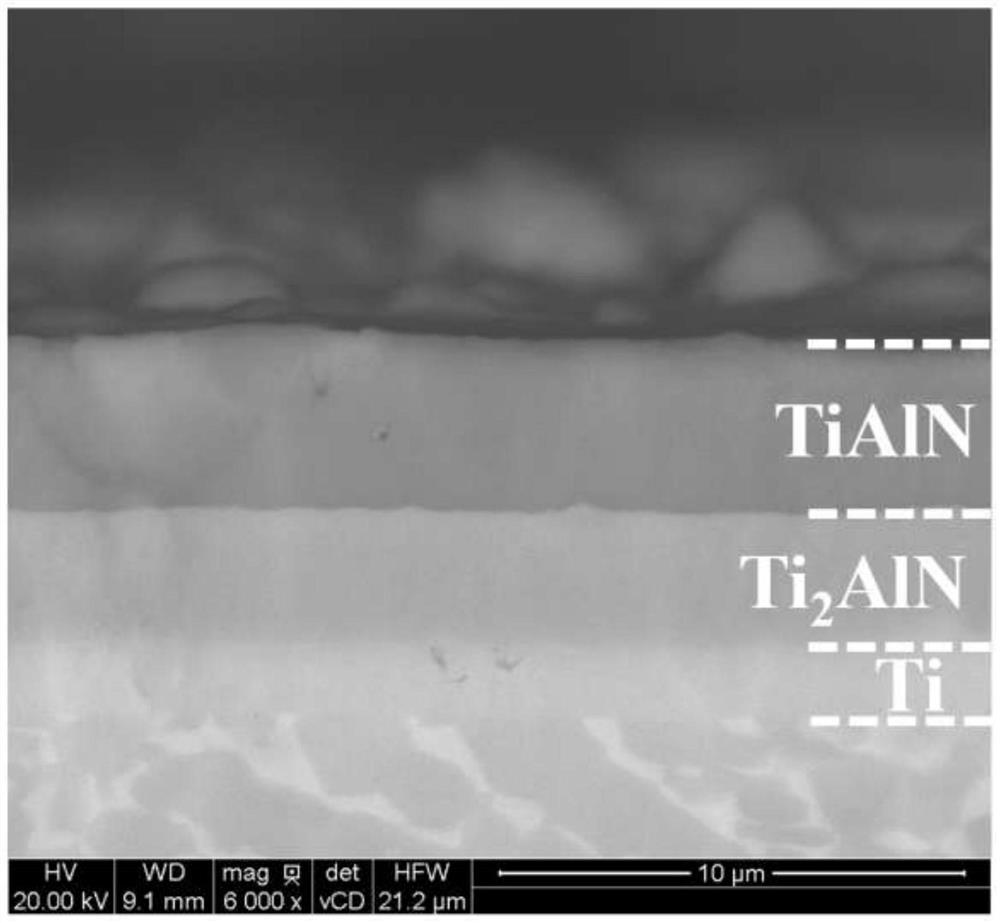

[0045] Such as figure 1 As shown, the titanium alloy substrate is cleaned with degreasing agent, acetone and absolute ethanol in sequence, and the cleaned and dried titanium alloy substrate is put into the vacuum chamber, and argon gas of 35.0 sccm is first introduced into the vacuum chamber. , set the current of the linear anode ion source to 0.2A, and the chamber pressure to 0.2Pa, use ionized argon ions to etch the substrate for 30min; The bias voltage is -70V, the arc current is 70A, the Ar gas pressure is 6.0Pa, and the deposition thickness is 2.0μm; then the Ti-Al-N transition layer is deposited by arc ion plating technology combined with DC magnetron sputtering technology, and the reaction gas is introduced Nitrogen and argon, the mixed gas pressure is 2.7Pa, the proportion of nitrogen to the total gas flow is 8%, the arc current is 70A, the DC magnetron sputtering power is 3000W, the bias voltage is -200V, and the thickness is 6.0μm; the third In the first step, arc i...

Embodiment 2

[0048] Put the cleaned and dried titanium alloy substrate into the vacuum chamber, firstly pass argon gas 35.0sccm into the vacuum chamber, set the current of the linear anode ion source to 0.2A, and the chamber pressure to 0.2Pa. The substrate was etched with argon ions for 30 minutes; then the Ti bonding layer was deposited by arc ion plating technology, the target material was Ti target, the negative bias voltage of the substrate was -70V, the arc current was 70A, the Ar gas pressure was 6.0Pa, and the deposition thickness was 1.5 μm; then use the arc ion plating technology combined DC magnetron sputtering technology to deposit the Ti-Al-N transition layer, feed the reaction gas nitrogen and argon, the mixed gas pressure is 2.7Pa, and the proportion of nitrogen to the total gas flow is 8% , the arc current is 70A, the DC magnetron sputtering power is 3000W, the bias voltage is -200V, and the thickness is 5.5μm; the third step adopts the arc ion plating technology to deposit ...

Embodiment 3

[0051] Put the cleaned and dried titanium alloy substrate into the vacuum chamber, firstly pass argon gas 35.0sccm into the vacuum chamber, set the current of the linear anode ion source to 0.2A, and the chamber pressure to 0.2Pa. The substrate was etched with argon ions for 30 minutes; then the Ti bonding layer was deposited by arc ion plating technology, the target was a Ti target, the negative bias of the substrate was -70V, the arc current was 70A, the Ar gas pressure was 6.0Pa, and the deposition thickness was 2.0 μm; then use the arc ion plating technology combined DC magnetron sputtering technology to deposit the Ti-Al-N transition layer, feed the reaction gas nitrogen and argon, the mixed gas pressure is 2.7Pa, and the proportion of nitrogen to the total gas flow is 8% , the arc current is 70A, the DC magnetron sputtering power is 3000W, the bias voltage is -200V, and the thickness is 6.0μm; the third step is to use arc ion plating technology to deposit the TiAlN surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com