Amino resin modified novolac epoxy resin anti-corrosion stain-resistant powder coating and metal precast slab anti-corrosion stain-resistant coating

A phenolic epoxy resin, amino resin modification technology, applied in epoxy resin coatings, powder coatings, anti-corrosion coatings, etc., can solve the problem of insufficient surface hardness of pure epoxy powder coatings and poor surface release properties of metal prefabricated boards , not resistant to sand and gravel scratches, etc., to achieve the effect of low friction coefficient, hydrophobicity, easy demoulding, and strong alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

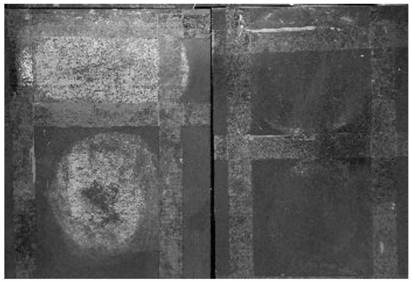

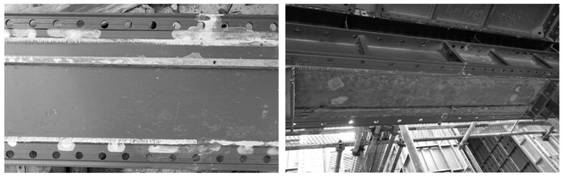

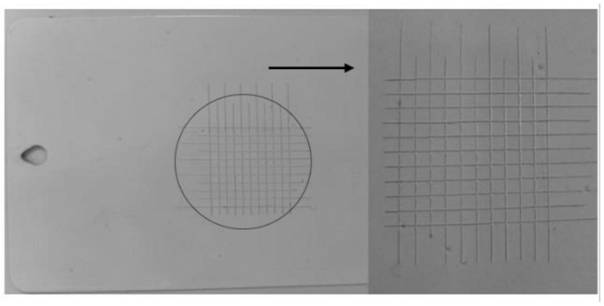

Image

Examples

preparation example Construction

[0037] In the present invention, the preparation method of described amino resin modified novolac epoxy resin preferably comprises the following steps:

[0038] The amino resin, the novolac epoxy resin, the quaternary ammonium salt catalyst and the organic solvent are mixed, and the modification reaction is carried out to obtain the amino resin modified novolak epoxy resin.

[0039] In the present invention, the quaternary ammonium salt catalyst is preferably one or more of benzyltriethylammonium chloride, benzyltrimethylammonium bromide and ethyltriphenylammonium bromide. In the present invention, the mass ratio of the novolac epoxy resin to the quaternary ammonium salt catalyst is preferably 100:0.1-2, more preferably 100:1.

[0040] In the present invention, the organic solvent is preferably one or more of toluene, xylene, dimethyl sulfoxide and n-hexane.

[0041] In the present invention, the mixing method is preferably stirring and mixing. In the present invention, the ...

Embodiment 1

[0078] A kind of anti-corrosion and stain-resistant coating for metal building prefabricated panels

[0079] Wherein anti-corrosion and stain-resistant powder coating formulation (parts by mass):

[0080]

[0081] The preparation of amino resin modified novolac epoxy resin:

[0082] Add 50 parts of o-cresol novolac epoxy resin to a 500ml three-necked flask, continue to add 150 parts of toluene solution, and continue stirring to dissolve at a speed of 500r / min. After the system is completely dissolved, add a total of 33 parts of melamine formaldehyde resin in three times, add 11 parts each time, keep stirring at a constant speed until completely dissolved, continue adding 0.5 parts of benzyltriethylammonium chloride catalyst to the three-necked flask, linear Raise the temperature to 90°C, control the heating rate at 5°C / min, continue the reaction for 2 hours, and the reaction ends. The reaction product is removed from the solvent by vacuum, which is the desired amino resin...

Embodiment 2

[0086] A kind of anti-corrosion and stain-resistant coating for metal building prefabricated panels

[0087] Wherein anti-corrosion and stain-resistant powder coating formulation (parts by mass):

[0088]

[0089]

[0090] The preparation of amino resin modified novolac epoxy resin:

[0091] Add 50 parts of phenol novolac epoxy resin into a 500ml three-necked flask, continue to add 150 parts of toluene solution, and continue stirring to dissolve at a speed of 500r / min. After the system is completely dissolved, add a total of 30 parts of urea-formaldehyde resin three times, adding 10 parts each time, keep stirring at a constant speed until it is completely dissolved, continue to add 0.5 parts of benzyltriethylammonium chloride catalyst to the three-necked flask, and raise the temperature linearly To 90°C, the heating rate was controlled at 5°C / min, the reaction was continued for 2 hours, and the reaction ended. The reaction product is removed from the solvent by vacuum,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com