Closed-pore ceramic microsphere filled gradient ceramic coating and preparation method thereof

A technology of ceramic coating and ceramic microspheres, which is applied in the field of ceramic coating, can solve the problem of unstable closed pores of porous ceramics, achieve low thermal conductivity, good high temperature chemical stability, and avoid the effect of connecting pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

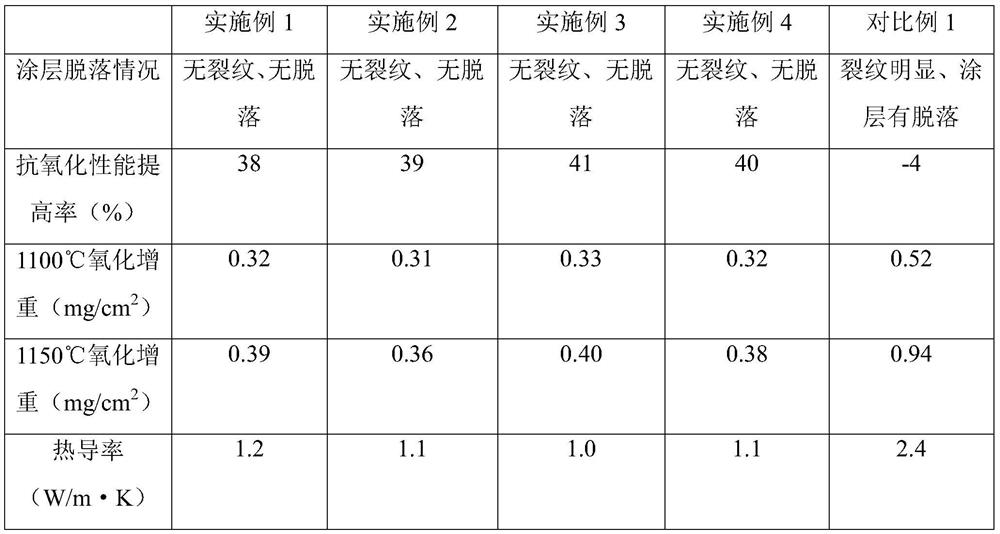

Examples

preparation example Construction

[0027] The present invention designs a kind of preparation method of gradient ceramic coating filled with closed-cell ceramic microspheres, and the specific steps are as follows:

[0028] S1. Preparation of solid microspheres

[0029] A Use aluminum salt as the precursor, add solvent, and prepare alumina sol by heating and hydrolyzing; the mass ratio of alumina sol to silica sol is (2-5):1, add silica sol and mix evenly, at 35-60°C Treat under the same conditions for 2-5 hours to obtain a silicon-aluminum composite sol with a viscosity of 16.8-45.0mPa·s;

[0030] B. Immerse organic resin microspheres with a particle size of 10-30 μm in the composite sol for 10-30 minutes, take them out and keep them in an oven at 100-120°C for 12-24 hours, then impregnate the microspheres in the composite sol, heat-preserve and dry, according to The thickness of the microspheres is repeated 2 to 5 times to obtain solid microspheres with a particle size of 40-80 μm;

[0031] S2, preparation o...

Embodiment 1

[0039] S1. Preparation of solid microspheres

[0040] A Take an appropriate amount of aluminum isopropoxide, add it to a three-necked bottle, add distilled water with a molar ratio of 110:1 to aluminum isopropoxide, stir it magnetically, and slowly add nitric acid dropwise after reflux at a constant temperature of 85°C for 4 hours to control the pH value of the solution. Between 3.5 and 5.5, reflux at constant temperature for 24 hours to obtain alumina sol;

[0041] According to the mass ratio of alumina sol to silica sol is 3:1, add silica sol and mix evenly, and treat at 55°C for 3 hours to obtain a silica-alumina composite sol with a viscosity of 28.0-33.0mPa·s;

[0042] B. Immerse polystyrene microspheres with a particle size of 20 μm in the composite sol for 30 minutes, take them out and keep them in an oven at 105 ° C for 12 hours, then soak the microspheres in the composite sol, heat and dry them, and repeat the operation 3 times to obtain the particle size Solid micro...

Embodiment 2

[0050] S1. Preparation of solid microspheres

[0051] A Take an appropriate amount of aluminum isopropoxide, add it to a three-necked bottle, add distilled water with a molar ratio of 110:1 to aluminum isopropoxide, stir it magnetically, and slowly add nitric acid dropwise after reflux at a constant temperature of 85°C for 4 hours to control the pH value of the solution. Between 3.5 and 5.5, reflux at constant temperature for 24 hours to obtain alumina sol;

[0052] According to the mass ratio of alumina sol to silica sol is 3:1, add silica sol and mix evenly, and treat at 55°C for 3 hours to obtain a silica-alumina composite sol with a viscosity of 28.0-33.0mPa·s;

[0053] B. Immerse silicone resin microspheres with a particle size of 20 μm in the composite sol for 30 minutes, take them out and keep them in an oven at 105 ° C for 12 hours, then soak the microspheres in the composite sol, heat and dry them, and repeat the operation 4 times to obtain the particle size Solid mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com