High-thermal-conductivity corrosion-resistant CuFe alloy, plate strip and preparation method of high-thermal-conductivity corrosion-resistant CuFe alloy

A high thermal conductivity, alloy plate technology, applied in heat treatment equipment, manufacturing tools, heat treatment furnaces, etc., can solve the problems of affecting the thermal conductivity of Cu-Fe alloys, weakening the corrosion resistance of Cu-Fe alloys, and shortening the service life of alloys. To achieve the effect of reasonable alloy composition, short production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

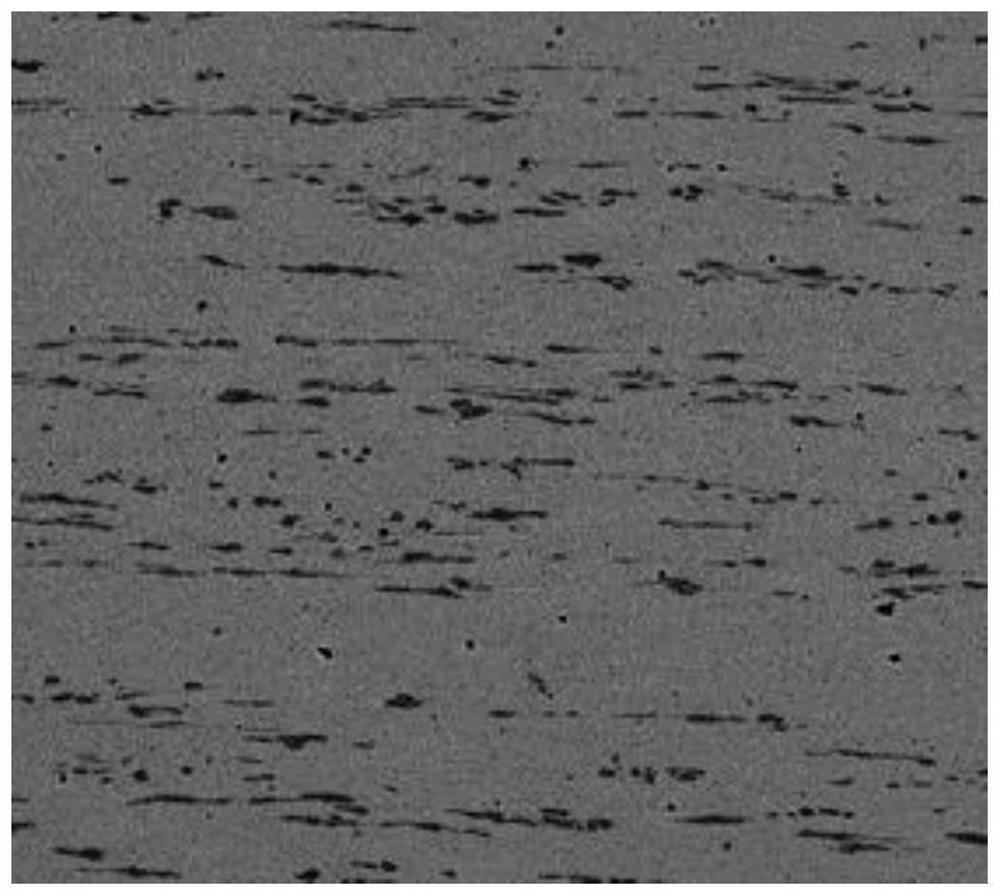

Image

Examples

Embodiment 1

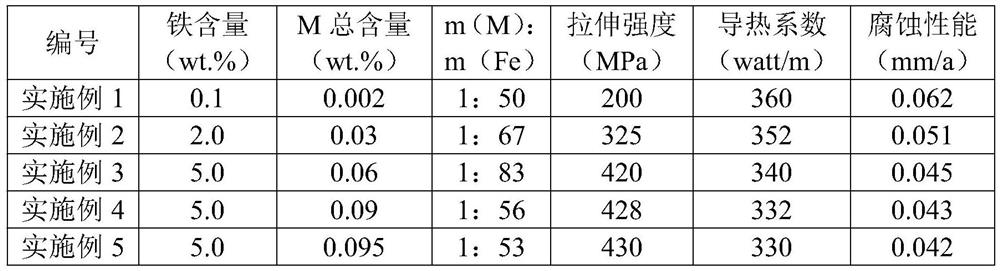

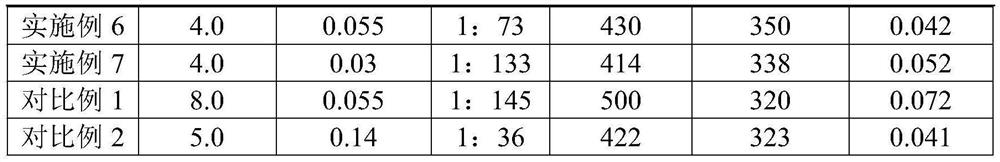

[0033] A high thermal conductivity and corrosion resistant CuFe alloy, in terms of mass percentage, the high thermal conductivity and corrosion resistant CuFe alloy contains the following components in mass content: Fe 0.1%, Si 0.001%, P 0.001%, and the total content of M elements is 0.002 %, the mass ratio of the total mass percentage of each element in the M element to Fe is 1:50; the rest is Cu and unavoidable impurities.

[0034] The high thermal conductivity and corrosion resistant CuFe alloy plate and strip of this embodiment is prepared from the above high thermal conductivity and corrosion resistant CuFe alloy by melting and casting.

[0035]The preparation method of the high thermal conductivity and corrosion-resistant CuFe alloy strip of the present embodiment comprises the following steps:

[0036] (1) Prepare materials according to the weight percentage of the element composition, first put the raw materials with good ratio into the heating furnace and melt them, t...

Embodiment 2

[0043] A high thermal conductivity and corrosion resistant CuFe alloy, in terms of mass percentage, the high thermal conductivity and corrosion resistant CuFe alloy contains the following components in mass content: Fe 2.0%, Sn 0.01%, Cr 0.01%, Al 0.01%, M element The total content is 0.03%, and the mass ratio of the total mass percentage of each element in the M element to Fe is 1:67; the rest is Cu and unavoidable impurities.

[0044] The high thermal conductivity and corrosion resistant CuFe alloy plate and strip of this embodiment is prepared from the above high thermal conductivity and corrosion resistant CuFe alloy by melting and casting.

[0045] The preparation method of the high thermal conductivity and corrosion-resistant CuFe alloy of the present embodiment comprises the following steps:

[0046] (1) Prepare materials according to the weight percentage of the element composition. First put the copper source, iron source, tin source, chromium source and aluminum sour...

Embodiment 3

[0053] A high thermal conductivity and corrosion resistant CuFe alloy, in weight percentage, the high thermal conductivity and corrosion resistant CuFe alloy contains the following components in mass content: Fe 5.0%, Si 0.01%, Ge 0.01%, V 0.02%, Ni 0.02% , The total content of M element is 0.06%, the mass ratio of the total mass percentage of each element in M element to Fe is 1:83; the rest is Cu and unavoidable impurities.

[0054] The high thermal conductivity and corrosion resistant CuFe alloy plate and strip of this embodiment is prepared from the above high thermal conductivity and corrosion resistant CuFe alloy by melting and casting.

[0055] The preparation method of the high thermal conductivity and corrosion-resistant CuFe alloy of the present embodiment comprises the following steps:

[0056] (1) Prepare materials according to the weight percentage of the element composition. Firstly, put the copper source, iron source, silicon source, germanium source, vanadium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com