Process for preparing Teflon high-temperature cloth based on impregnation method

A Teflon, high temperature cloth technology, applied in textiles and papermaking, etc., can solve the problems of complex impregnation process, poor high temperature resistance, long time consumption, etc., and achieves retention of existing characteristics, excellent high temperature resistance, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment prepares a kind of modified graphene oxide, and the steps are as follows:

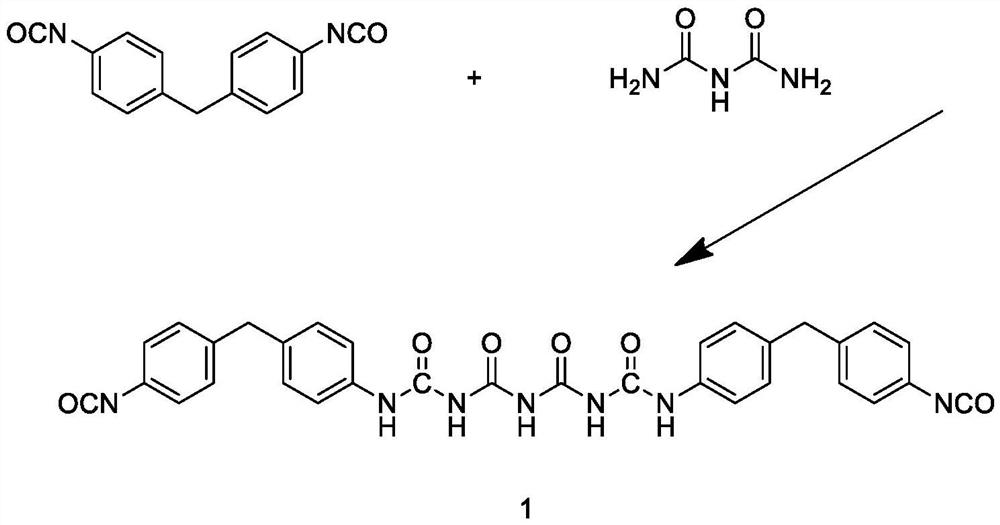

[0031] Step A1. Add 0.05 mol of diphenylmethane diisocyanate and 58 mL of benzene into a three-necked flask in a water bath, stir for 10 minutes, add 0.025 mol of biuret, and stir at 80°C for 1 hour. After the reaction, remove the solvent benzene by rotary evaporation , to obtain intermediate 1;

[0032]Step A2: Add 1.3g of graphene oxide and 65.8mL of DMF into a three-necked flask, ultrasonically disperse at a frequency of 40kHz for 10min, then add 0.3g of intermediate 2 and dibutyltin dilaurate to the three-necked flask, heat up to reflux for 2h, After the reaction, cool to room temperature, transfer the reaction product to ice water, stir at 100r / min for 20min, centrifuge, wash the precipitate with acetone and distilled water three times in sequence, and finally dry it in an oven at 60°C to constant weight to obtain an intermediate product ; The consumption of dibutylt...

Embodiment 2

[0035] The present embodiment prepares a kind of modified graphene oxide, and the steps are as follows:

[0036] Step A1. Add 0.05mol of diphenylmethane diisocyanate and 60mL of benzene into a three-necked flask in a water bath, stir for 10 minutes, add 0.025mol of biuret, and stir at 80°C for 1 hour. After the reaction, remove the solvent benzene by rotary evaporation , to obtain intermediate 1;

[0037] Step A2: Add 1.4g of graphene oxide and 70.5mL of DMF into a three-necked flask, ultrasonically disperse at a frequency of 45kHz for 10min, then add 0.4g of intermediate 2 and dibutyltin dilaurate to the three-necked flask, heat up to reflux for 3h, After the reaction, cool to room temperature, transfer the reaction product to ice water, stir at 150r / min for 20min, centrifuge, wash the precipitate with acetone and distilled water three times in sequence, and finally dry it in an oven at 60°C to constant weight to obtain an intermediate product ; The consumption of dibutyl ti...

Embodiment 3

[0040] The present embodiment prepares a kind of modified graphene oxide, and the steps are as follows:

[0041] Step A1. Add 0.06 mol of diphenylmethane diisocyanate and 64 mL of benzene into a three-necked flask in a water bath, stir for 10 minutes, add 0.025 mol of biuret, and stir at 80°C for 1 hour. After the reaction, remove the solvent benzene by rotary evaporation , to obtain intermediate 1;

[0042] Step A2: Add 1.5g of graphene oxide and 72.4mL of DMF into a three-necked flask, ultrasonically disperse at a frequency of 50kHz for 10min, then add 0.5g of intermediate 2 and dibutyltin dilaurate to the three-necked flask, heat up to reflux for 4h, After the reaction, cool to room temperature, transfer the reaction product to ice water, stir at 200r / min for 20min, centrifuge, wash the precipitate with acetone and distilled water three times in sequence, and finally dry it in an oven at 60°C to constant weight to obtain an intermediate product ; The consumption of dibutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com