Method for smelting ultra-low carbon stainless steel in vacuum induction furnace

A vacuum induction furnace and ultra-low carbon technology, which is applied in the field of vacuum induction furnace smelting, can solve the problems of smelting ultra-low carbon stainless steel without a vacuum induction furnace and other problems, and achieve the effect of ensuring the decarburization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

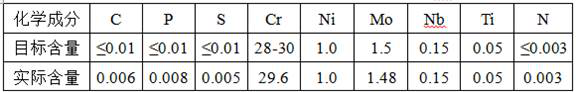

Embodiment 1

[0034] This embodiment adopts a vacuum induction furnace with a rated capacity of 50kg, its rated power is 140kw, and the ultimate vacuum degree is 6.67×10 -2 Pa, the chemical composition and target content of ultra-low carbon stainless steel are shown in Table 1. The smelting steps are as follows:

[0035] (1) Before smelting, bake and dry industrial pure iron, metal chromium, ferromolybdenum, iron ore, nickel plate, ferroniobium, and metal titanium at 120-180°C for 4-6 hours.

[0036] (2) Arrange 5kg of small pieces of industrial pure iron and 0.5kg of nickel plate at the bottom of the crucible, 1.25kg of ferromolybdenum with a molybdenum content of 60% is placed in the middle, and 28kg of industrial pure iron is placed in the upper part; 0.05kg of iron ore, 16kg of metal chromium, 0.02 kg of aluminum particles, 0.125kg of ferroniobium, and 0.025kg of titanium metal are put into the distribution bin.

[0037] (3) Vacuumize to 10Pa and power on, and all the raw materials in...

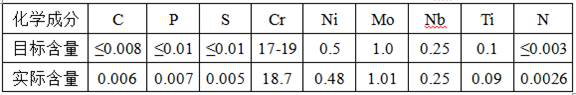

Embodiment 2

[0047] This embodiment adopts a vacuum induction furnace with a rated capacity of 500kg, its rated power is 400kw, and the ultimate vacuum degree is 6.67×10 -2 Pa, the chemical composition and target content of ultra-low carbon stainless steel are shown in Table 2. The smelting steps are as follows:

[0048](1) Before smelting, bake and dry industrial pure iron, metal chromium, ferromolybdenum, iron ore, nickel plate, ferroniobium, and metal titanium at 120-180°C for 4-6 hours.

[0049] (2) 50kg of small pieces of industrial pure iron and 2.5kg of nickel plate are arranged at the bottom of the crucible, 8.33kg of ferromolybdenum with a molybdenum content of 60% is placed in the middle, and 342.17kg of industrial pure iron is placed in the upper part; 0.5kg of iron ore, 98kg of metal chromium, 0.2kg of aluminum pellets, 2.08kg of ferroniobium, and 0.5kg of titanium metal are put into the distribution bin.

[0050] (3) Vacuumize to 8Pa and power on, and after 2.5 hours, all th...

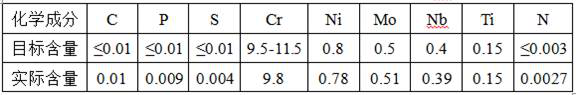

Embodiment 3

[0060] In this embodiment, a vacuum induction furnace with a rated capacity of 1t is used, with a rated power of 750kw and a limit vacuum of 0.1Pa. The chemical composition and target content of ultra-low carbon stainless steel are shown in Table 3. The smelting steps are as follows:

[0061] (1) Before smelting, bake and dry industrial pure iron, metal chromium, ferromolybdenum, iron ore, nickel plate, ferroniobium, and metal titanium at 120-180°C for 4-6 hours.

[0062] (2) 200kg of small pieces of industrial pure iron and 8kg of nickel plate are arranged at the bottom of the crucible, 8.34kg of ferromolybdenum with a molybdenum content of 60% is placed in the middle, and 675.26kg of industrial pure iron is placed in the upper part; 1.5kg of iron ore, 105kg of metallic chromium, 0.6 kg of aluminum particles, 6.67kg of ferroniobium, and 1.5kg of titanium metal are put into the distribution bin.

[0063] (3) Vacuumize to 5Pa and power on, and all the raw materials in the cruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com