Flame retardant and preparation method thereof

A technology of flame retardant and epoxy phosphate ester, which is applied in the field of organic chemical synthesis, can solve the problems of poor heat resistance of flame retardant epoxy resin, increase of epoxy resin, and difficult processing, etc., and achieve simple process, low cost and easy cost , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

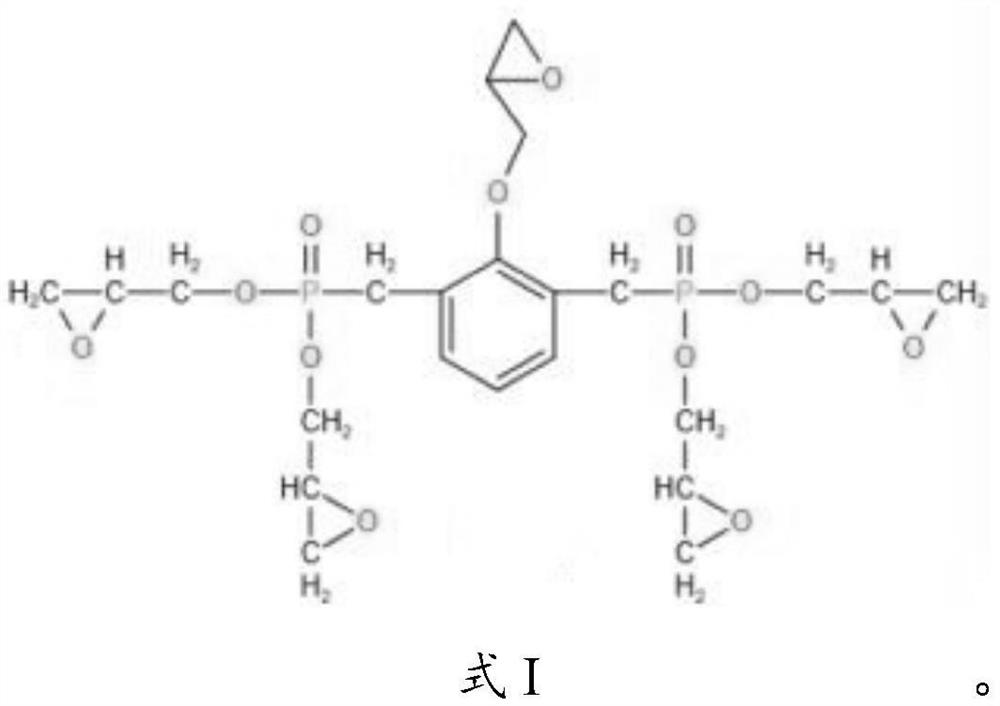

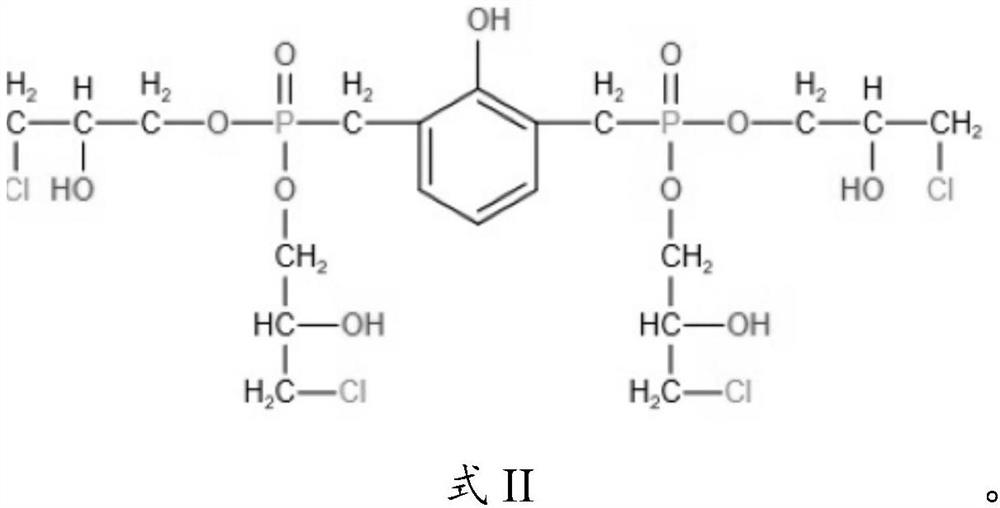

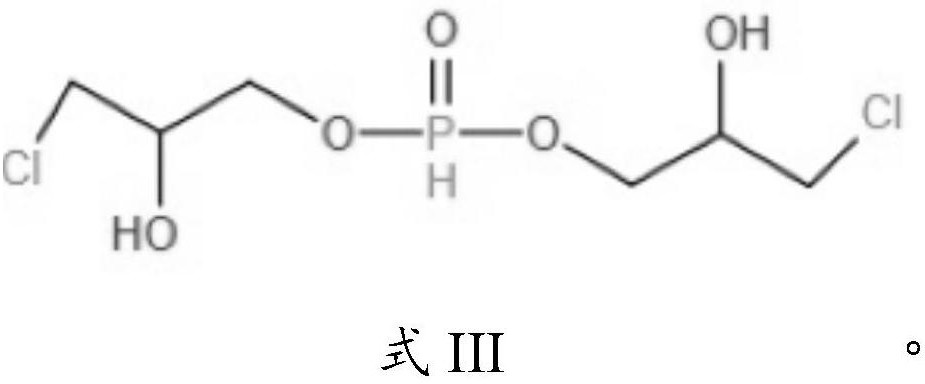

[0029] The synthetic route involved is as follows:

[0030]

[0031] The specific process steps are as follows:

[0032] (1) Put 3.5mol 3-chloropropanediol into the reactor and heat up to 105°C, turn on the vacuum pump to evacuate to 35torr, and dehydrate to below 0.05%; reduce the temperature of the reactor to 25°C, slowly drop the toluene solution of phosphorus trichloride Put it into the reaction kettle (the mass ratio of phosphorus trichloride and toluene is 3:1), the dropwise addition is an exothermic reaction, and the dropping rate is properly adjusted to keep the temperature between 25°C and 35°C; the reaction will release HCl, and the reaction will be connected to the tail pipe Collect HCl, slowly raise the temperature to 90°C after the dropwise addition, and keep it warm until there is no release; raise the temperature to 135°C and turn on the vacuum pump, and extract the by-products and toluene out of the reactor to obtain the intermediate product 1;

[0033] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com