A kind of resin composition and the copper clad board made thereof

A resin composition, epoxy resin technology, applied in layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of high price and high cost, achieve high Tg value, excellent flexural performance, The effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

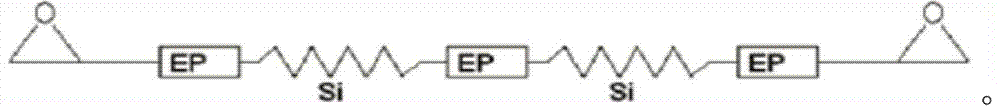

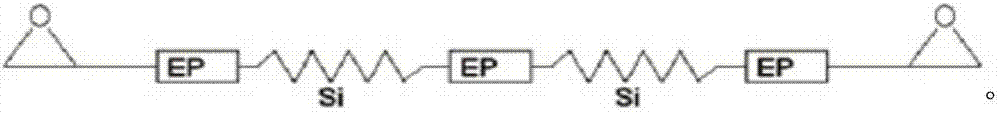

Method used

Image

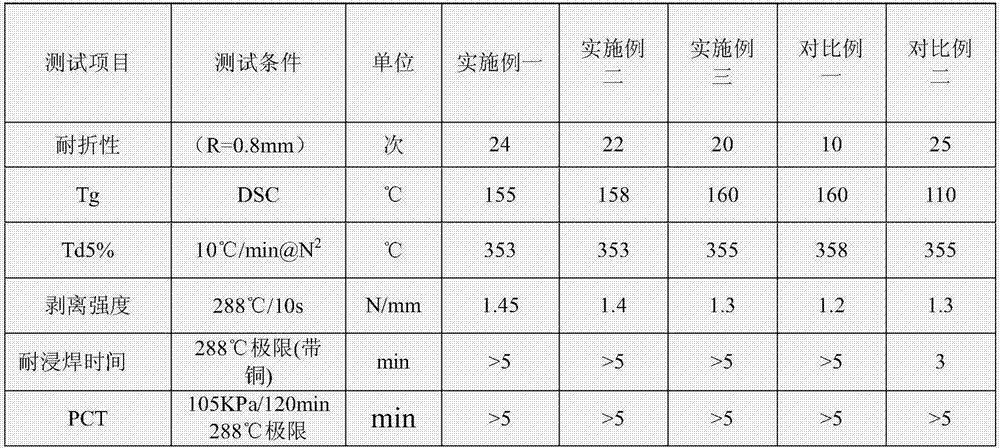

Examples

Embodiment 1

[0020] A resin composition, comprising the following components by weight: 50 parts of phosphorus-containing epoxy resin (Dow Chemical, XZ92530), 10 parts of novolac epoxy resin (HEXION, EPR627), silicone rubber core-shell structure modification 16 parts of epoxy resin (Evonik Hans, ALBIDUR EP2240A), 20 parts of silicone-epoxy block copolymer (Evonik Hans, ALBIFLEX296), 4 parts of dicyandiamide.

[0021] Described resin composition prepares the method for prepreg, comprises the steps:

[0022] Add an imidazole accelerator and a solvent to the composition to form a glue solution, stir and mix evenly, soak 1080 glass fiber cloth in the glue solution, bake in an oven at 155°C for 5 minutes to remove the solvent, and obtain a prepreg.

[0023] Preparing a copper clad laminate with the prepreg comprises the following steps:

[0024] Use a single prepreg, cover the top and bottom with a 18μ electrolytic copper foil, and laminate in a vacuum press. The lamination conditions are 190°...

Embodiment 2

[0027] A resin composition, comprising the following components by weight: 60 parts of phosphorus-containing epoxy resin (Dow Chemical, XZ92530), 7 parts of novolak epoxy resin (HEXION, EPR627), silicone rubber core-shell structure modification 20 parts of epoxy resin (Evonik Hans, ALBIDUR EP2240A), 10 parts of silicone-epoxy block copolymer (Evonik Hans, ALBIFLEX296), 3 parts of dicyandiamide.

[0028] Described resin composition prepares the method for prepreg, comprises the steps:

[0029] Add an imidazole accelerator and a solvent to the composition to form a glue solution, stir and mix evenly, soak 1080 glass fiber cloth in the glue solution, bake in an oven at 155°C for 5 minutes to remove the solvent, and obtain a prepreg.

[0030] Preparing a copper clad laminate with the prepreg comprises the following steps:

[0031] Use a single prepreg, cover the top and bottom with a 18μ electrolytic copper foil, and laminate in a vacuum press. The lamination conditions are 190°C...

Embodiment 3

[0034] A resin composition, comprising the following components by weight: 70 parts of phosphorus-containing epoxy resin (Dow Chemical, XZ92530), 5 parts of novolak epoxy resin (HEXION, EPR627), silicone rubber core-shell structure modification 10 parts of epoxy resin (Evonik Hans, ALBIDUR EP2240A), 13 parts of silicone-epoxy block copolymer (Evonik Hans, ALBIFLEX296), 2 parts of dicyandiamide.

[0035] Described resin composition prepares the method for prepreg, comprises the steps:

[0036] Add an imidazole accelerator and a solvent to the composition to form a glue solution, stir and mix evenly, soak 1080 glass fiber cloth in the glue solution, bake in an oven at 155°C for 5 minutes to remove the solvent, and obtain a prepreg.

[0037] Preparing a copper clad laminate with the prepreg comprises the following steps:

[0038] Use a single prepreg, cover the top and bottom with a 18μ electrolytic copper foil, and laminate in a vacuum press. The lamination conditions are 190°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com