A kind of nano-ceramic composite 6201 aluminum alloy, its ultrasonic-assisted low-temperature synthesis method and its application

A nano-ceramic and ultrasonic-assisted technology, which is applied in the field of aluminum alloys, can solve problems such as multiple side reactants, complex processes, and environmental pollution, and achieve the effects of accelerating chemical reactions, simple chemical reaction processes, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

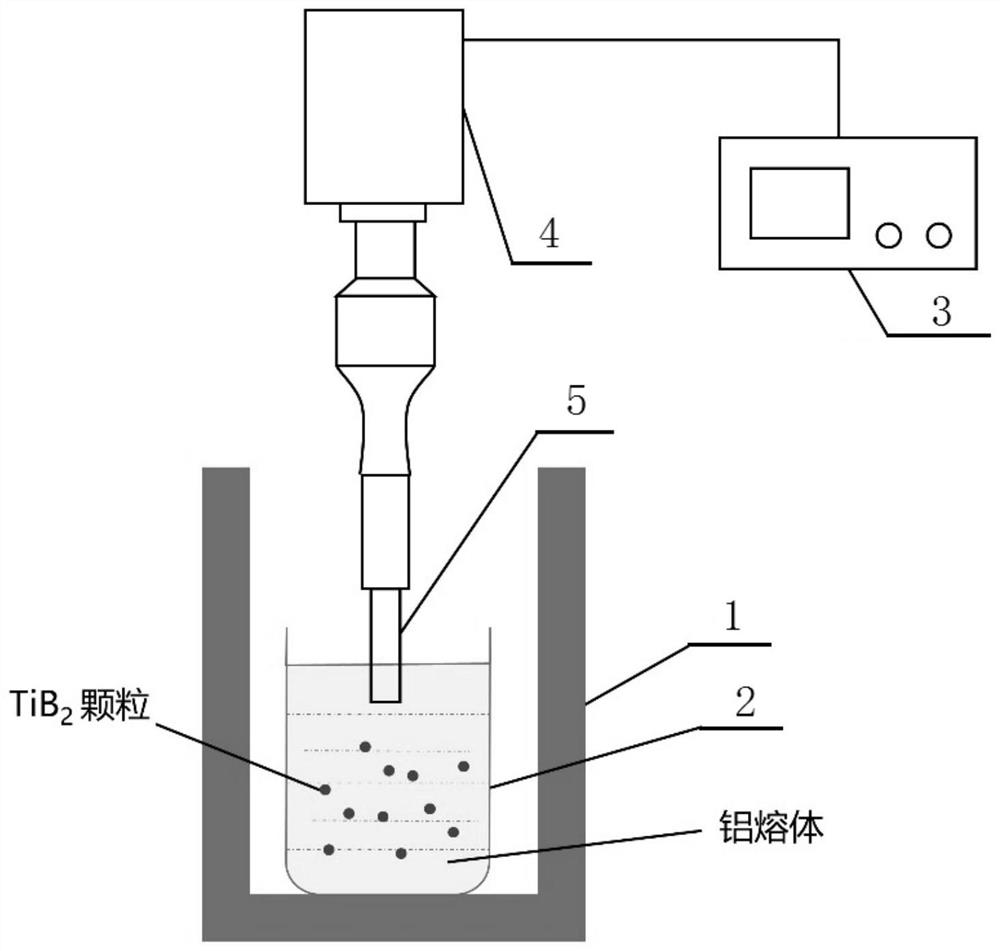

[0045] This embodiment discloses the ultrasonic-assisted low-temperature synthesis method of five kinds of nano-ceramic composite 6201 aluminum alloys. The device used in this method is as follows: figure 2 As shown, it includes a resistance furnace 1 and an ultrasonic device, wherein the resistance furnace is used to heat and insulate the melt in the crucible 2, and the ultrasonic device is composed of a generator 3, a converter 4, a horn and a TC4 probe 5, and the generator is directly connected The power supply and the horn are connected by threads.

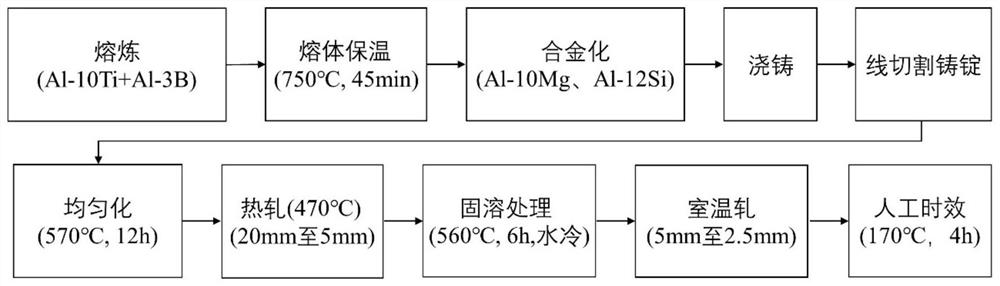

[0046] The ultrasonic-assisted low-temperature synthesis method of nano-ceramic composite 6201 aluminum alloy in this embodiment is as follows: figure 1 shown, including the following steps:

[0047] Step 1. Prepare raw materials Al-10wt.%Ti, Al-3wt.%B, Al-10wt.%Mg and Al-12wt.%Si master alloys, and generate TiB according to the complete reaction of raw materials 2 The premise is to carry out the ratio calculation, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com