A kind of anti-formaldehyde self-cleaning wall paint and preparation method thereof

A self-cleaning, wall paint technology, applied in the field of self-cleaning wall paint and its preparation, can solve the problem of difficult curing and removal of formaldehyde, and achieve the effect of realizing biomass killing, improving process performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Polychromic acid can be prepared by known electrochemical polymerization method, using aqueous solution of chromotropic acid as electrolyte, sodium hydroxide as supporting electrolyte, glassy carbon electrode as working electrode, and reacting according to conventional electrochemical polymerization process.

[0037] The present invention also adds 10-15 parts of diatomite, diatomaceous earth is a porous substance, and mixing it with film-forming substances and fusion chromic acid can increase the specific surface area of the wall paint surface, and the fusion chromatic acid can be attached in the pores And acrylate film-forming substances can better absorb formaldehyde on the surface of wall paint and provide a place for curing reaction. At the same time, diatomite itself can shorten the drying time, enhance the feel of the film, and increase the wear resistance, scratch resistance and permeability of the coating film.

Embodiment 1

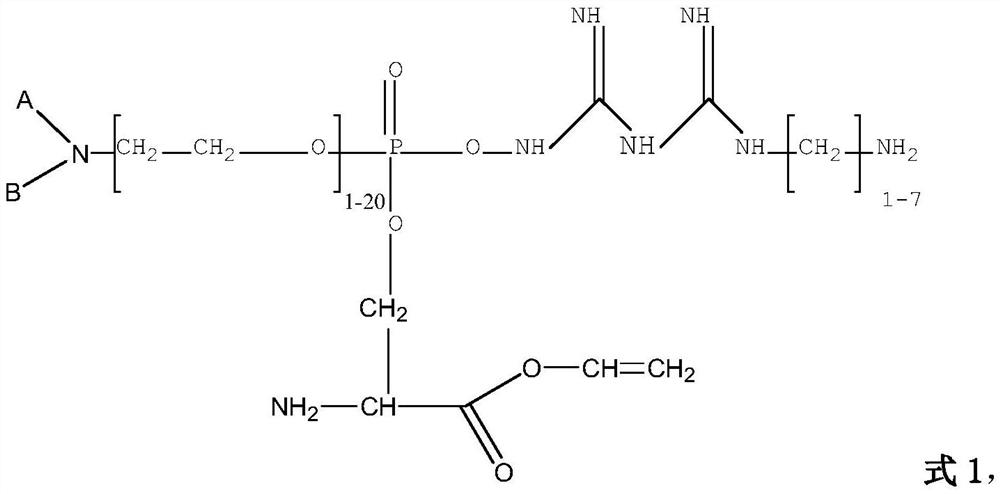

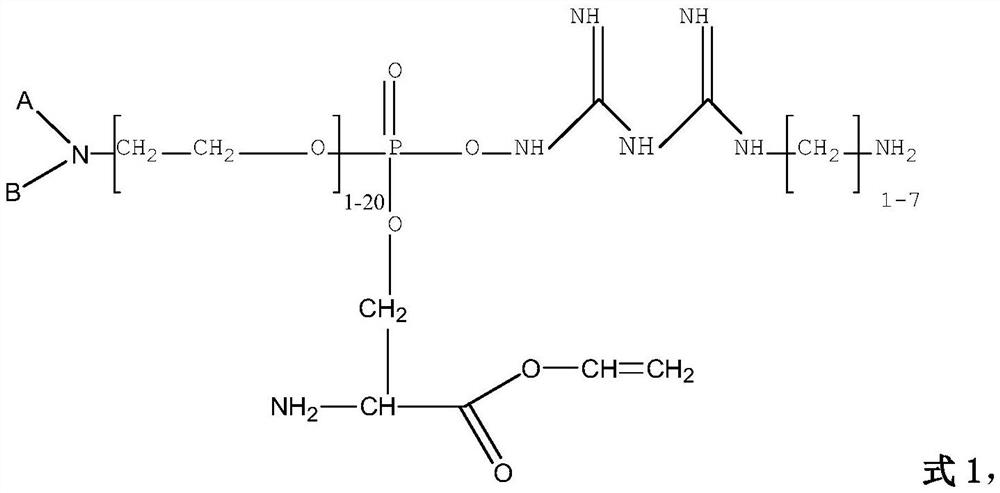

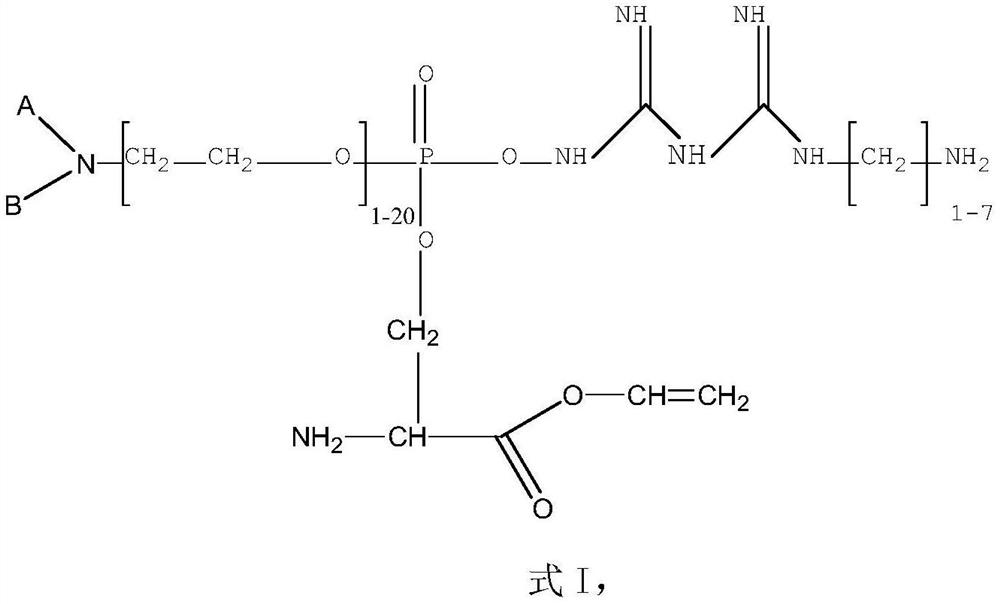

[0056] Embodiment 1: Preparation of guanidine-containing hydrophilic compound

[0057] Dissolve phosphorus trichloride in tetrahydrofuran solution, lower the temperature to 0°C, slowly add dimethylamino-terminated PEG-600 into the solution, stir the solution at 5°C for 5min, then add 2,6-lutidine , stirring reaction at 5°C; at the same time, serine was added to the tetrahydrofuran solution, and then 2,6-lutidine was added for stirring, and the mixed solution was added to the above reaction solution containing phosphorus trichloride and PEG, at 5°C Stir the reaction, after reacting for 2 hours, add aminopropyl biguanide to the reaction solution, then lower the temperature to 0°C, add sodium bromide and keep the temperature at 0°C, after the addition is complete, raise the temperature to room temperature at room temperature, and stir reaction. Detect that the reaction is complete by TLC, add sodium metabisulfite to consume unreacted oxidant after the reaction is complete, add e...

Embodiment 2

[0060] Heat a mixture of 15 parts by weight of water, 1 part of ammonium persulfate and 0.4 part of sodium dodecylsulfonate to 50°C, add 15 parts of methyl methacrylate, 10 parts of butyl acrylate, and 10 parts of 2-hydroxypropyl acrylate, 1 part of guanidine-containing hydrophilic compound prepared in Example 1, carry out emulsion polymerization reaction 6h under the speed of stirring at 200r / min to obtain polymerized emulsion; 0.5 part of polychromic acid, defoamer Add 0.4 parts, 2 parts of propylene glycol, and 1 part of dodecyl alcohol ester to the polymerized emulsion, stir at a stirring speed of 500r / min to obtain a mixed solution; stir each of 5 parts of kaolin and heavy calcium, 10 parts of diatomaceous earth and 10 parts of deionized water Evenly, add to the above mixture, stir at 900r / min to obtain the mixture; measure pH, 0.4 parts of hydroxyethyl cellulose and 0.1 part of 2-amino 2-methyl-1 propanol are finally added to the mixture, and stir Uniformly, obtain the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com