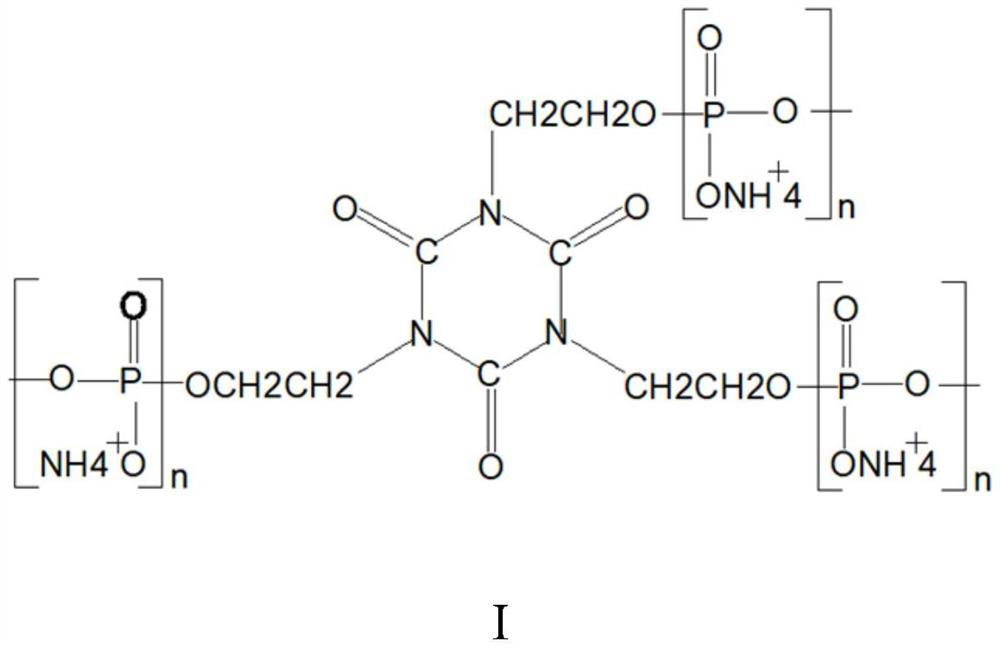

Ammonium polyphosphate flame retardant as well as preparation method and application thereof

A technology of ammonium polyphosphate and flame retardant, which is applied in the field of flame retardant materials to achieve the effects of good thermal stability, stable viscosity and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of preparation method of ammonium polyphosphate flame retardant, comprises the steps:

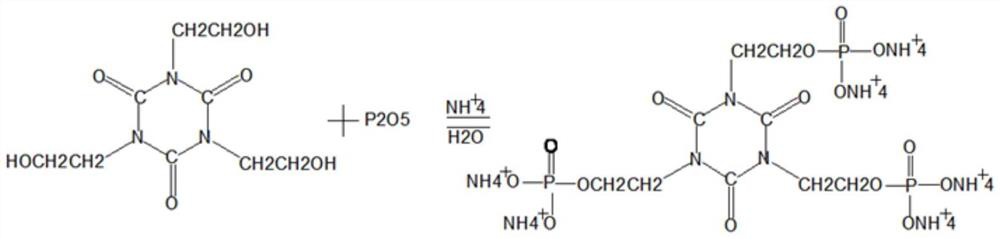

[0039] Preparation of ammonium phosphate salt containing triazine ring in S1:

[0040] Replace the air in the reactor with nitrogen for 15 minutes, put 55.2kg of trishydroxyethyl isocyanurate and 44.8kg of phosphorus pentoxide into the reactor, stir and raise the temperature to 80°C; open the ammonia flow, the ammonia flow is 6.5m 3 / h, the ammonia passing time is 4h; at the same time as the ammonia passing, open the interval spray to add water, the interval time is 5 minutes, the amount of water added each time is 50g, and the total amount of water added is 2kg; after the reaction is completed, the ammonium phosphate salt containing the triazine ring is prepared, and then opened Reactor, the material is cooled and crushed for later use.

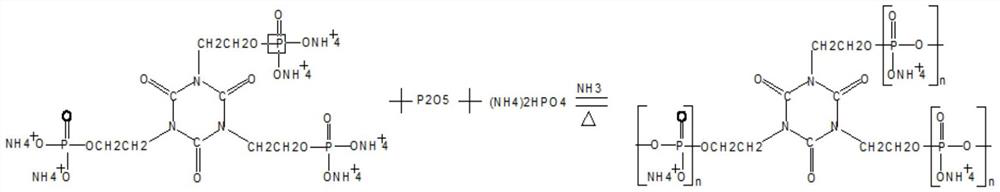

[0041] S2 Polymerization:

[0042] Replace the air in the kneader with nitrogen for 10 minutes, put into ...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of ammonium polyphosphate flame retardant, comprises the steps:

[0046] Preparation of ammonium phosphate salt containing triazine ring in S1:

[0047] Replace the air in the reactor with nitrogen for 15 minutes, put 55.2kg of trishydroxyethyl isocyanurate and 44.8kg of phosphorus pentoxide into the reactor, stir and raise the temperature to 80°C; open the ammonia flow, the ammonia flow is 6.5m 3 / h, the ammonia passing time is 4h; open the spray and add water while passing the ammonia, open the interval spray and add water while passing the ammonia, the interval time is 5 minutes, the amount of water added each time is 50g, and the total amount of water added is 2.0kg; The ammonium phosphate salt of oxazine ring, then open the reaction kettle, the material is cooled and crushed for later use.

[0048] S2 Polymerization:

[0049] Replace the air in the kneader with nitrogen for 10 minutes, put into the knea...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of ammonium polyphosphate flame retardant, comprises the steps:

[0053] Preparation of ammonium phosphate salt containing triazine ring in S1:

[0054] Replace the air in the reactor with nitrogen for 15 minutes, put 55.2kg of trishydroxyethylisocyanurate and 44.8kg of phosphorus pentoxide into the reactor, stir and heat up to 100°C; open the ammonia flow, the amount of ammonia flow is 5.0m 3 / h, the time of passing ammonia is 5h; when passing ammonia, open interval spraying and add water, the interval time is 5 minutes, the amount of water added each time is 50g, and the total amount of water added is 2.0kg; the reaction is completed and the ammonium phosphate salt containing triazine ring is obtained, Open the reaction kettle, the material is cooled and crushed for later use.

[0055] S2 Polymerization:

[0056] Replace the air in the kneader with nitrogen for 10 minutes, put into the kneader 25 kg of amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com